Maintenance (continued) – Shindaiwa GP344 User Manual

Page 13

13

IMPORTANT!

If a new gasket is not available and/

or the old gasket is not damaged, the

old gasket may be reused. Never use

cracked or damaged gaskets!

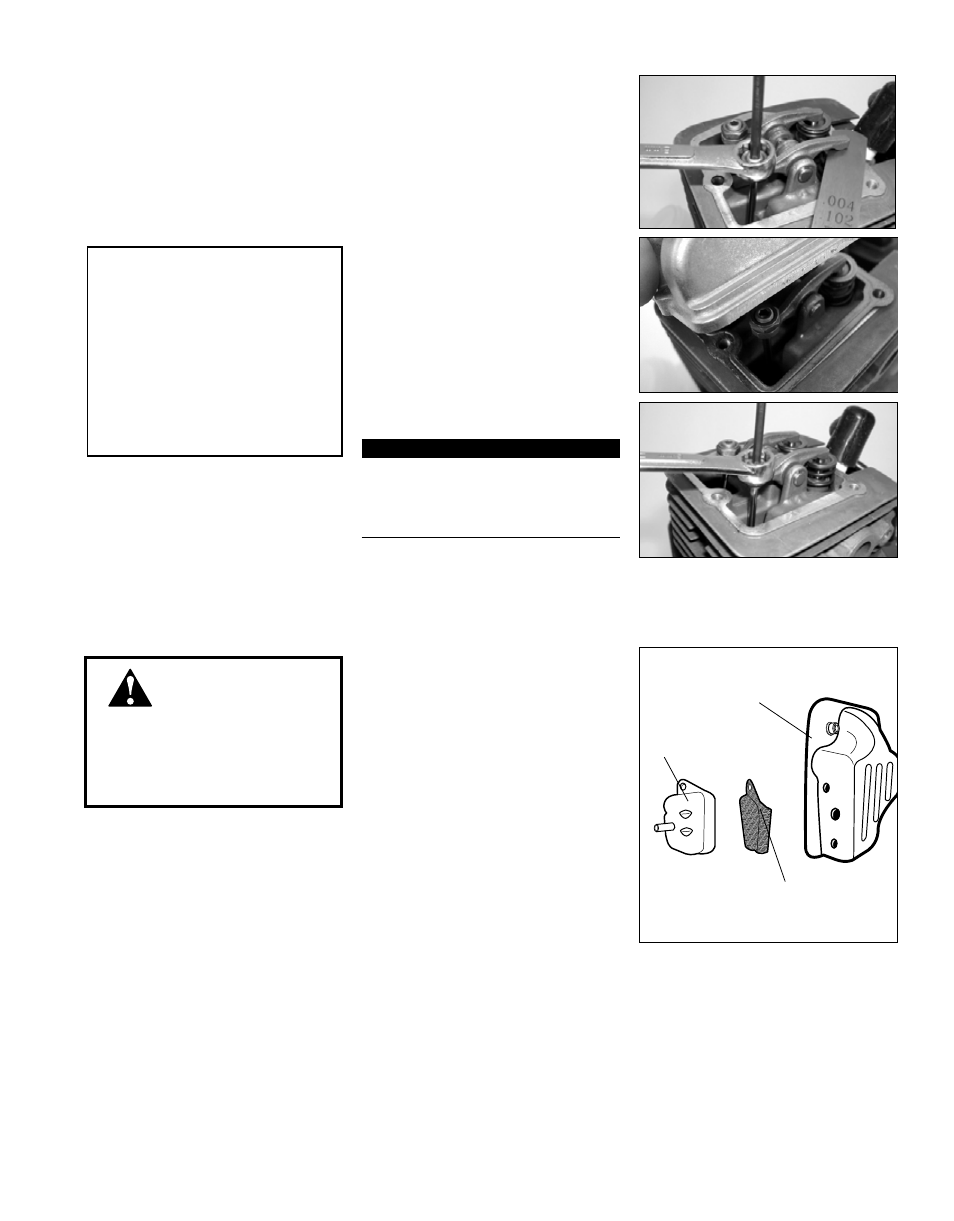

Turn adjustment screw (clockwise =

4.

tighter, counter-clockwise = looser)

until feeler gauge is almost snug.

Back off just enough to allow gauge

to slip out with limited resistance.

While holding the adjustment

5.

screw in place with the Allen driver,

tighten the locknut with a wrench.

Turn engine over several times, and

6.

returnthe to TDC-compression.

Recheck with proper feeler gauge

to make sure clearance adjust-

ment did not change as a result of

tightening the locknut. Readjust as

necessary.

Replace rocker arm cover gasket

7.

to assure proper sealing and install

cover.

Remove cylinder cover, rocker arm

1.

cover, and spark plug. Rotate the

crankshaft while observing the piston

through the spark plug opening. When

the piston is at the top of the compres-

sion stroke (TDC), the valves can be

adjusted.

Loosen adjuster locknut so that the

2.

2.5 mm Allen socket head adjust-

ment screw can turn freely.

Insert 0.10 mm feeler gauge

3.

between valve stem tip and rocker

arm.

CAUTION!

Performing a valve adjustment

■

incorrectly may cause hard

starting and/or can damage the

engine.

If you are unfamiliar with this

■

engine or uncomfortable with

this procedure, consult with an

authorized Shindaiwa servicing

dealer.

Valve Adjustment

Spark Arrester Maintenance

Hard starting or a gradual loss of perfor-

mance can be caused by carbon deposits

lodged in the spark arrester screen. For

maximum performance, the spark arrester

screen should be periodically cleaned as

follows.

Remove engine cover to expose

1.

muffler. Remove the spark arrester

from the muffler. The arrester is

press-fit in place; there are three

screws to remove.

Muffler

Spark Arrester

Screen

Figure 19

Spark Arrester

Screen Cover

Use a plastic scraper or wire brush

2.

to remove carbon deposits from

the arrester screen and wipe clean

exhaust base.

Inspect the screen carefully, and

3.

replace any screen that has been

perforated, distorted, or is otherwise

unserviceable.

Press the spark arrester into the

4.

exhaust base.

If carbon accumulation in the muffler

or cylinder are severe, or if you do not

notice an improvement in performance

after servicing, have the unit inspected

by an authorized servicing Shindaiwa

dealer.

WARNING!

Never operate this unit

with a damaged or missing muffler

or spark arrester! Operating with

missing or damaged exhaust com-

ponents is a fire hazard, and can

also damage your hearing!

Maintenance (continued)