Adjustments, Warning, Speed selector pivot adjustment – Snapper 555M User Manual

Page 23: Traction drive clutch cable adjustment

22

Adjustments

SPEED SELECTOR PIVOT ADJUSTMENT

The speed selector is factory set for optimal performance

at each forward and reverse speed setting. However, if

drive system components have been replaced, adjust-

ment may be necessary.

Adjust as follows:

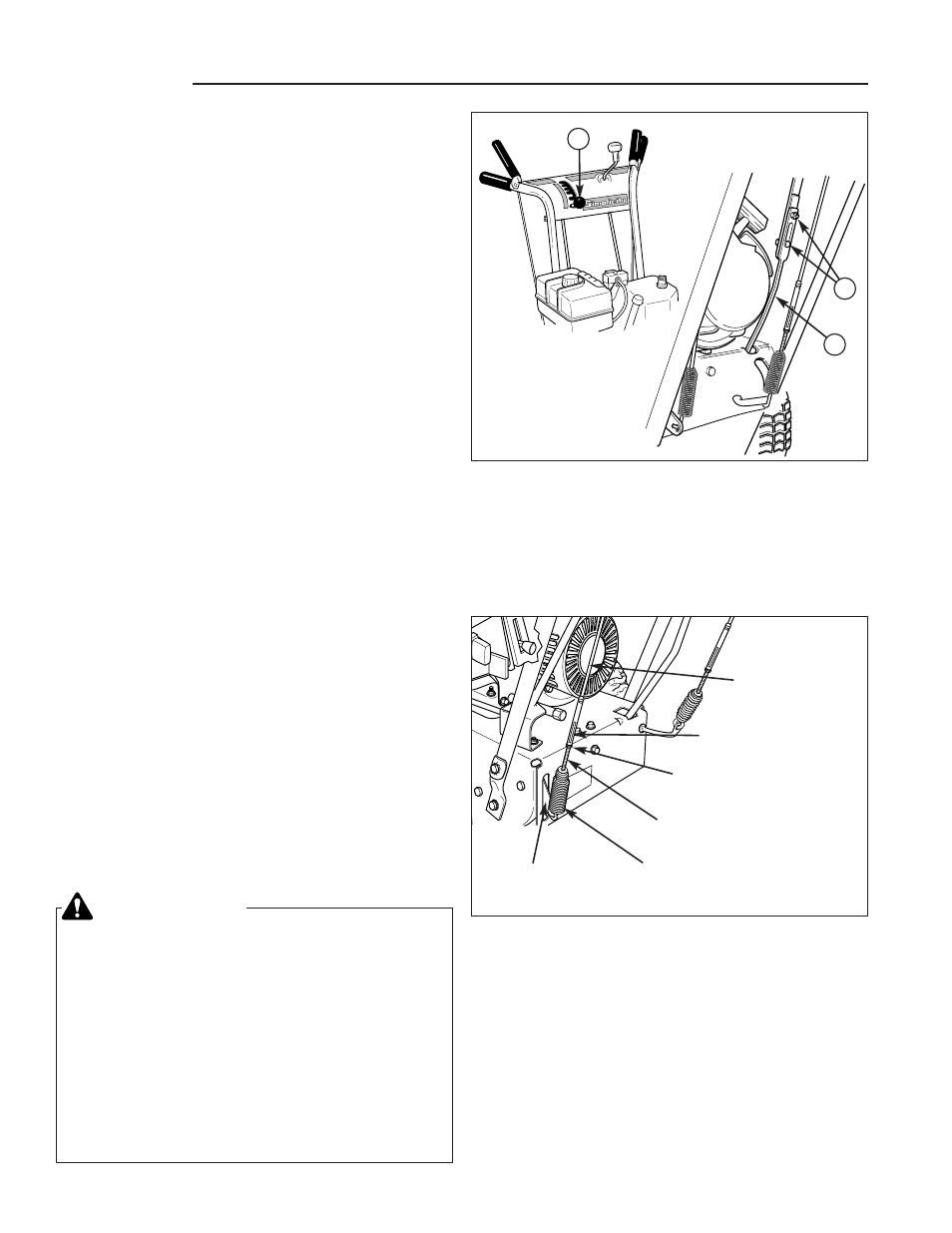

1. Move the ground speed control (A, Figure 19) fully

forward.

2. Loosen the hardware (B) securing the upper and

lower shift rods.

3. Push the lower rod (C) down fully (into the housing).

4. Make sure the ground speed control (A) is in the full

forward (5th gear) position. Pull the two rods apart

and tighten the shift rod hardware (B).

Figure 19. Speed Selector Linkage Adjustment

A. Ground Speed Lever

B. Shift Rod Hardware

C. Lower Shift Rod

TRACTION DRIVE CLUTCH CABLE

ADJUSTMENT

Initial Adjustment

The traction drive clutch cable should initially be adjusted

so that there is no slack in the cable when moved slightly

from side to side, but bellcrank arm remains in fully down

position. To adjust tension on the cable:

1. Loosen adjustment hex nut (Figure 20) by holding the

adjusting flats and turning adjustment hex nut.

2. Tighten adjustment screw by turning adjustment flats

and holding screw. The adjustment screw is a

phillips screw and the head can be held or turned by

inserting a screwdriver through the traction drive

clutch cable spring. Tighten just until slack in cable

is removed.

3. Tighten hex nut securely. The unit should able to be

pushed forward and back freely.

Figure 20. Traction Drive Clutch Cable Adjustment

Traction Drive

Clutch Cable

Traction Drive

Clutch Cable Spring

Adjustment

Screw

Traction Drive

Bellcrank Arm

Run-In Adjustment

1. After 5 hours of use, check for proper adjustment.

Readjust clutch cable if necessary by increasing ten-

sion on cable. A small amount of bellcrank arm

movement is permissible if unit passes operating

checks described in the Caution at left. Optimal

adjustment provides 3/16" clearance between

traction drive disc and rubber ring on friction disc

when drive lever is released (see Figure 15 for fric-

tion disk location).

WARNING

Do not over-tighten, as this may cause traction

drive to engage without depressing the traction

drive control (bellcrank arm must remain in down

position).

Verify that the cables are not over-tightened: With

speed selector in position 1 and traction drive

control fully released, push snowthrower forward.

The unit should move forward freely.

If unit does not move forward freely, the cable has

been over-tightened. To remedy, loosen tension

on clutch cable slightly, and recheck.

A

B

C

Adjustment

Flats

Adjustment

Hex Nut