Maintenance, Lubrication – Snapper 555M User Manual

Page 19

18

Maintenance

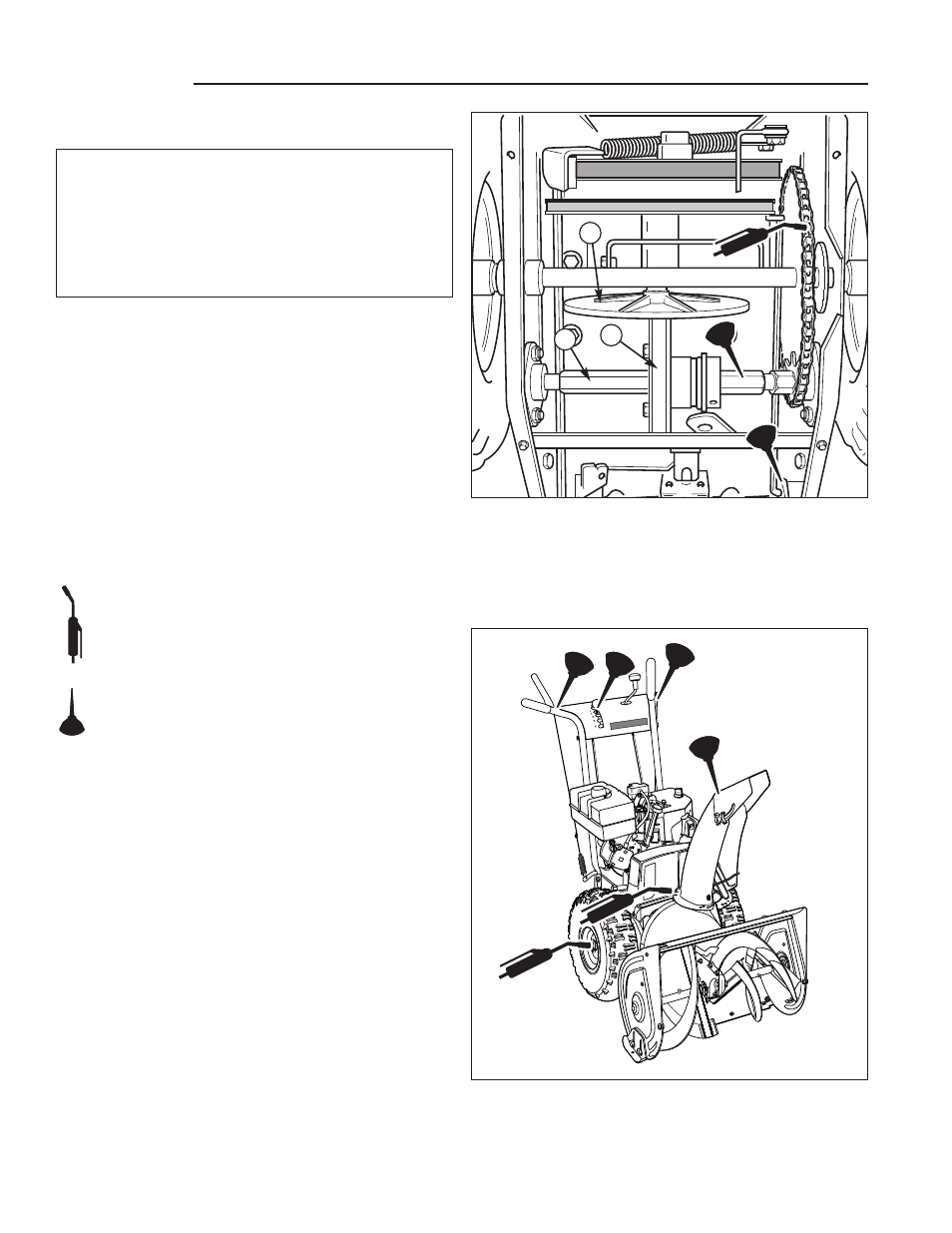

Figure 15. Drive Area Lubrication Points

(Bottom Cover Removed)

A. Drive Disc

C. Hex Shaft

B. Friction Disc

Figure 16. Snowthrower General Lubrication Points

A

B

C

Remove wheels and grease axles once each year.

There are two grease fittings on the auger shaft. Wipe

the fittings clean and apply grease, using a grease gun.

Also apply grease on other points indicated.

Apply medium weight (10W) oil to points shown (See

Figures 15 - 18).

Apply 5W-50 synthetic motor oil to the friction disc hex

shaft (see Figure 15).

Generally, all moving metal parts should be oiled where

contact is made with other parts. Keep oil and grease off

belts, pulley grooves, drive disc, and friction disc.

IMPORTANT NOTE

It is very important that grease fittings on the auger shaft

are lubricated regularly. If auger rusts to shaft, damage to

worm gear may occur if shear pins do not break.

To prevent wheels rusting to axles, it is also necessary

to remove the wheels and grease the axles regularly.

LUBRICATION

LUBRICATION NOTES:

Grease locations indicated by grease gun symbol.

Use grease fittings when present. Disassemble

parts to apply grease to moving parts when grease

fittings are not installed.

Oil locations indicated by oil can symbol. Do not

allow oil to drip onto traction drive or friction disc.