Installation / operation 4 – Simer Pumps 5020B-04 User Manual

Page 4

Installation / Operation

4

For parts or assistance, call Simer Customer Service at

1-800-468-7867

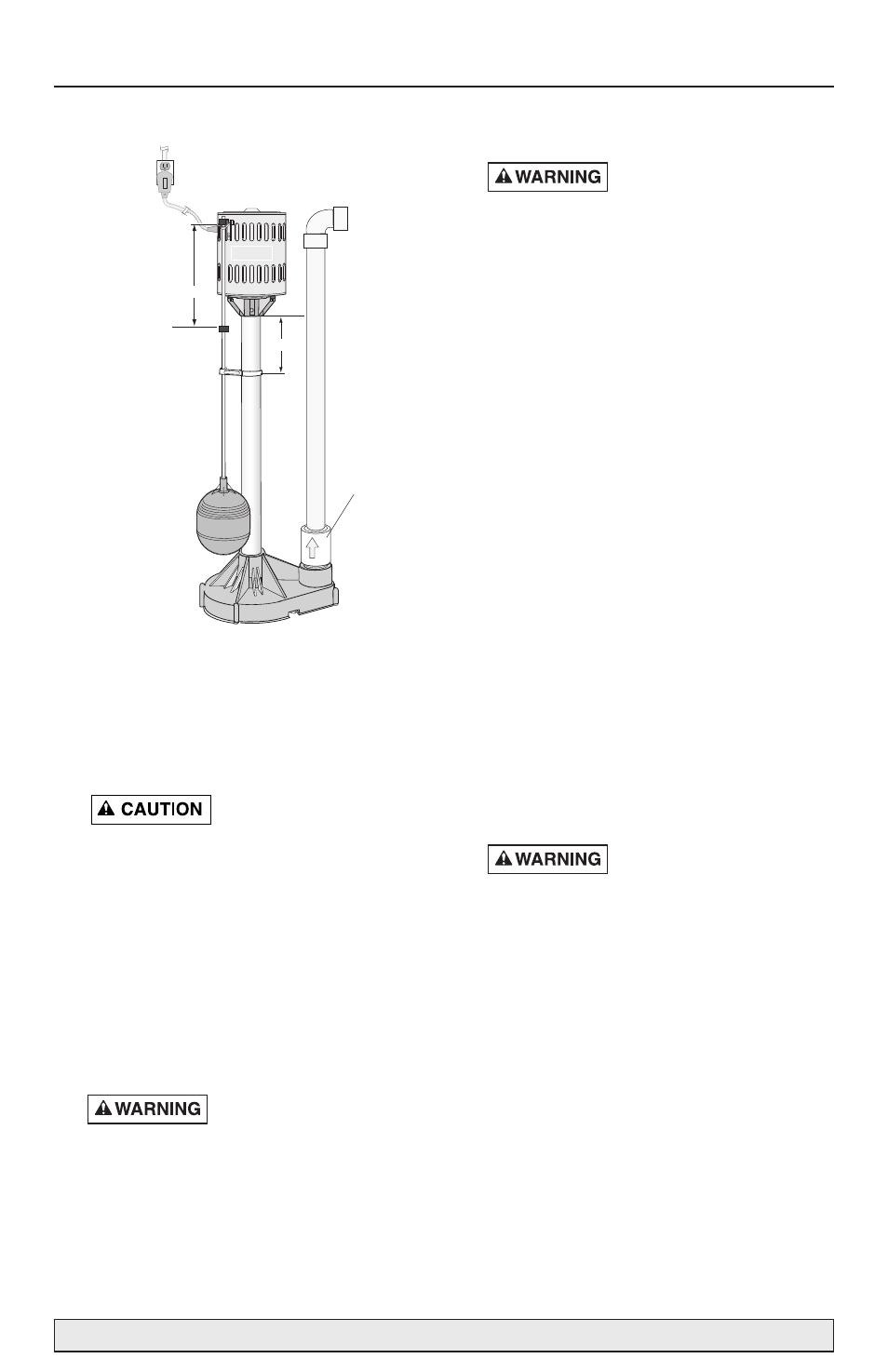

INSTALLATION

1.

This unit can be installed in sump pit with min-

imum diameter of 12"(30cm) and depth of 12"

(30cm). Sump pit may be constructed of tile,

concrete, steel or plastic. Check local codes for

approved materials.

2.

Install pump on solid, level foundation, as near

as possible to center of sump pit. Do not hang

pump from discharge pipe or power cord.

Pump must be level (column

must be vertical) when oper-

ating. If motor is tilted, internal start/run switch

may overheat and damage motor.

3.

Pump should not be installed on clay, earth or

sand surfaces. Clean sump pit of small stones

and gravel which could clog the pump. Keep

pump inlet screen clear.

4.

Thread discharge pipe into pump body careful-

ly to avoid stripping or crossing threads.

NOTICE: Do not use ordinary pipe joint com-

pound on plastic pipe or pump. Pipe joint com-

pound can attack plastics and damage pump.

5.

To reduce motor noise and vibrations, a short

length of rubber hose (1-5/8"(41mm) I.D., e.g.

radiator hose) can be connected into discharge

line near pump using suitable clamps.

Risk of electric shock. Pump

is designed for 115V., 60 HZ

operation and requires an individual branch

circuit of 15 amperes capacity. It is supplied

with a 3-wire cord set with grounding-type

plug for use in a 3-wire, grounded outlet. Do

not cut off the round grounding prong. For

safety, outlet must always be electrically

grounded to a suitable electrical ground such

as a grounded water pipe or a properly

grounded metallic raceway or ground wire sys-

tem.

6.

Locate Float Rod Guide (Key No. 6) about 6"

(16cm) below motor. Clamp guide to column

with screw provided.

Risk of flooding. Be sure that

guide is securely clamped so

that float rod is vertical and can move up and

down freely. If float is angled or binds, pump

may not start, allowing flooding to occur.

7.

Screw float onto threaded end of rod. Threads

on rod will cut threads into corrosion resistant

float.

8.

Insert plain end of float rod up through eye of

rod guide.

9.

Slide one rod stop on float rod before passing

rod through eye of pump switch. Slide 2nd rod

stop on rod after passing through eye of switch.

Position 2nd rod stop flush with top of rod.

10. Position lower rod stop to within 8"(20cm) of

switch lever arm. With lower rod stop in this

position, pump will automatically cycle at

approximately 2-1/2"(6cm) off and 10-12"(25-

30cm) on. For faster cycling, move lower rod

stop closer to switch lever arm.

11. If pump discharge line is exposed to outside

subfreezing atmosphere, then portion of line

exposed must be installed so any water remain-

ing in pipe will drain to outfall by gravity.

Failure to do this can cause water trapped in

discharge to freeze which could result in dam-

age to pump.

12. Install an in-line check valve to prevent flow

backwards through pump after pump shuts off.

NOTICE: Simer check valves are equipped with

an air bleed hole to prevent airlocking the

pump. If using a check valve that is not a Simer

valve, drill a 1/8" (3.2mm) hole in discharge

pipe just above pump body but below the

check valve to prevent air locks.

13. After all piping and controls have been

installed, unit is ready for operation.

14. Run pump through one cycle to check float

switch operation.

The pump motor is equipped

with automatic resetting

thermal protector and may restart unexpected-

ly. Protector tripping is an indication of motor

overloading as a result of operating pump at

low heads (low discharge restriction), exces-

sively high or low voltage, inadequate wiring,

incorrect motor connections, or a defective

motor.

Discharge

About 6"

About 8"

Check

Valve

(Purchase

Separately)