Caution warning caution caution, Caution – S&S Worldwide Motorcycle Accessories User Manual

Page 6

8.

Lower End Assembly (All)

NOTES:

●

All current production S&S

®

Evolution

®

Sportster

®

model

flywheels are made from closed die, heat treated, steel

forgings. They do not have connecting rod thrust washers

like earlier S&S or stock flywheels, because present flywheel

material is harder than thrust washers previously used.

●

S&S Sportster

®

model style flywheels come with three

timing marks, "F", "R" and "TF". The "F" mark stands for

front cylinder 30° before top dead center (TDC). The "R"

mark is rear cylinder 30° before TDC, The “TF” mark is TDC

front cylinder. When "F" or "R" mark is placed in center of

timing hole it means that cylinder is timed at 30° before

TDC. We recommend that big inch Sportster

®

engines be

timed at 30-32° before TDC rather than the stock 40°

before TDC. See Performance Notes, Ignition Timing.

●

Usually S&S flywheels are balanced before leaving our

facility. Some customers prefer to do their own balancing or

to have another balancing shop do the work for them. This

is acceptable in most cases. However, we have had some bad

experiences with dynamically balanced flywheels that have

forced us to void our guarantee if flywheels have been

balanced in this fashion.

Flywheels assembled improperly prior to being dynamically

balanced may sustain irreversible damage to mainshaft and

crankpin tapers during actual balancing. S&S voids its

guarantee if flywheels have been balanced in this fashion.

●

Many problems in assembling and truing flywheels can

be prevented by careful inspection of all parts used in

the assembly.

●

Cleaning parts prior to and during assembly and keeping

parts clean after final assembly are imperative to minimize

contaminants that may circulate in oil and shorten engine

life. Many parts can be cleaned with soap and water first.

Then, reclean all internal parts and gasket mating surfaces

using high quality solvent that does not leave any harmful

residues. Be sure to read and follow manufacturer’s

instruction label before use. Use drills and compressed air to

clean all oil passageways of dirt, filings, etc. whenever

possible. During actual final assembly, recoat all internal

parts with high quality engine oil or assembly lube such as

S&S 51-9000.

Manufacturing chips, dirt and/or other contaminants

circulating in engine oil may possibly damage engine

components resulting in shorter engine life and possible

engine failure.

●

Some solvents, degreasers, gasoline and other chemicals are

harmful to skin, eyes and other body parts. Many items are

flammable and present a fire hazard. Read manufacturer’s

instruction label for proper use. Use in well ventilated area

and wear protective clothing when using them to avoid

personal injury.

●

Compressed air and particles dislodged by compressed air

are harmful to eyes and body. Wear protective goggles

when using compressed air and always direct air stream

away from body parts such as hands and eyes. Never direct

compressed air toward other people.

Perform following steps when assembling flywheels:

A.

Thoroughly clean all parts to be used. This includes

mainshafts, main bearings, connecting rods, rod

bearings, keys and flywheels including tapers and

key ways.

Burrs, dirt, filings, etc. left on flywheel assembly parts may

circulate in oil damaging other parts possibly causing

engine failure.

B.

Inspect key ways and oil holes in flywheels for burrs and

remove if necessary.

NOTE: S&S does not recommend lapping tapers to remove burrs.

This practice tends to distort the taper by removing material

unevenly around the circumference. This makes flywheels

difficult if not impossible to true. In addition the lapping process

work hardens the surface of the taper. This hard surface makes

it very difficult to pull shaft or crankpin into taper. If crankpin

and shafts are not pulled fully into flywheel tapers, excessive rod

side play and assembly width may result. Lapped flywheel tapers

are also very difficult to resurface if repairs are ever needed.

S&S warranty is void if flywheel tapers are lapped.

C.

Check keys in grooves of shafts. Key should be light

hand press fit in groove. If key is too tight in groove,

sand side key with fine sand paper on a metal plate or

other flat surface. Do not hammer key into groove.

Hammering tight key into groove may result in irreparable

damage to shaft.

6

CAUTION

WARNING

CAUTION

CAUTION

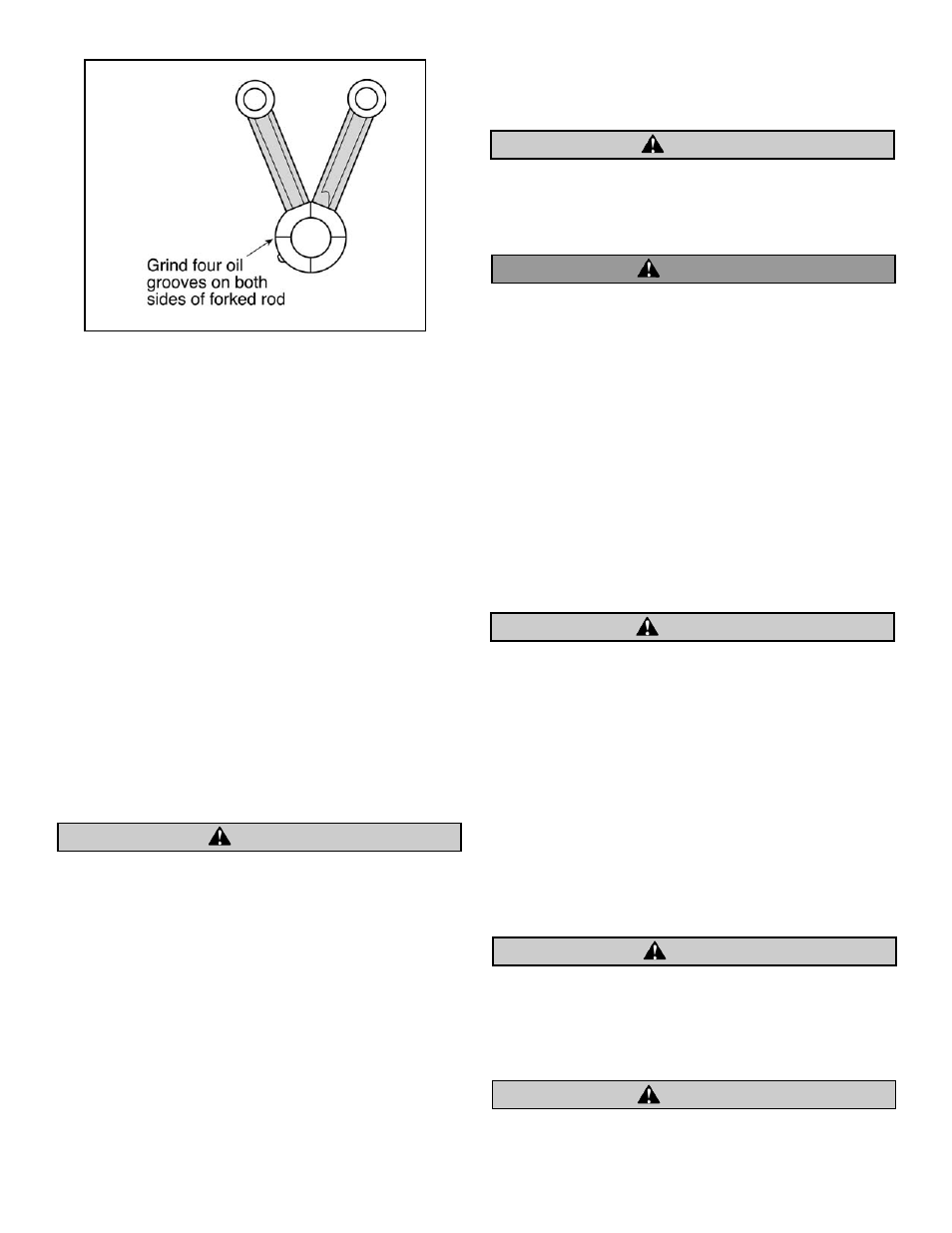

Figure 2

CAUTION

CAUTION