Snap-On 870013 User Manual

Page 5

COMPONENT INSTALLATION

Never use a non-relieving air coupler with the angled

finish nailer. Always use couplers that release any built-up charge in the angled

finish nailer’s firing mechanism. A non-relieving air coupler can allow the angled

finish nailer to discharge a fastener while the tool is disconnected from the

power source. Failure to comply with this warning can result in serious or per-

manent injury or even death to the operator or to bystanders.

When selecting an air compressor, it must comply with the requirements of the

American National Safety Institute - ANSI B19.3.

Choose an air compressor that can supply more than the required air pressure to

ensure optimum efficiency. Always use clean, dry compressed air with a maximum

pressure of 200 psi. Use a pressure regulator and set the pressure between 70 –

120 psi. (5.0 – 8.5 kg/cm

2

G). Before each use, check the pressure regulator to

ensure it is functioning within the proper pressure range.

Using an air pressure of more than 120 psi can

cause the angled finish nailer to malfunction or possibly explode

causing severe injury or property damage.

SELECTING A PROPER AIR HOSE

Use an air hose with the largest diameter and shortest length possible to ensure

continuous, efficient nailing operations. Using an air pressure of 70 psi (5.0

kg/cm

2

G), an air hose with an inside diameter of 1/4" (6.5 mm) or greater and a hose

length of less than 6.6 ft (20 m), it is recommended that a 0.5 second interval be

allowed between each nailing. Air supply hoses shall have a minimum working pres-

sure of 150 psi (10.7 kg/cm

2

G) or 150% of the maximum pressure produced by the

compressor or whichever is higher.

Low air output by the compressor or a longer hose with

a smaller inside diameter in relation to the nailing frequency may decrease

the driving capability of the air nailer.

SELECTING A QUICK DISCONNECT

1. Remove the plastic protective plug

from the tool’s air inlet.

2. Insert a 1/4" NPT male quick

disconnect into the air inlet. Install the female portion to the air hose.

Thoroughly clean and maintain the angled finish nailer after every use.

Lubricate moving parts to prevent rust and minimize friction-related wear. Wipe

down the entire tool and remove all dust from the moving parts. Properly store

the angled finish nailer in a suitable case to keep it ready for the next job.

All maintenance and repairs should be performed by an authorized repair

facility. Call 1-888-278-8092 to obtain a list of repair facilities in your area or

to make arrangements to return the tool for service.

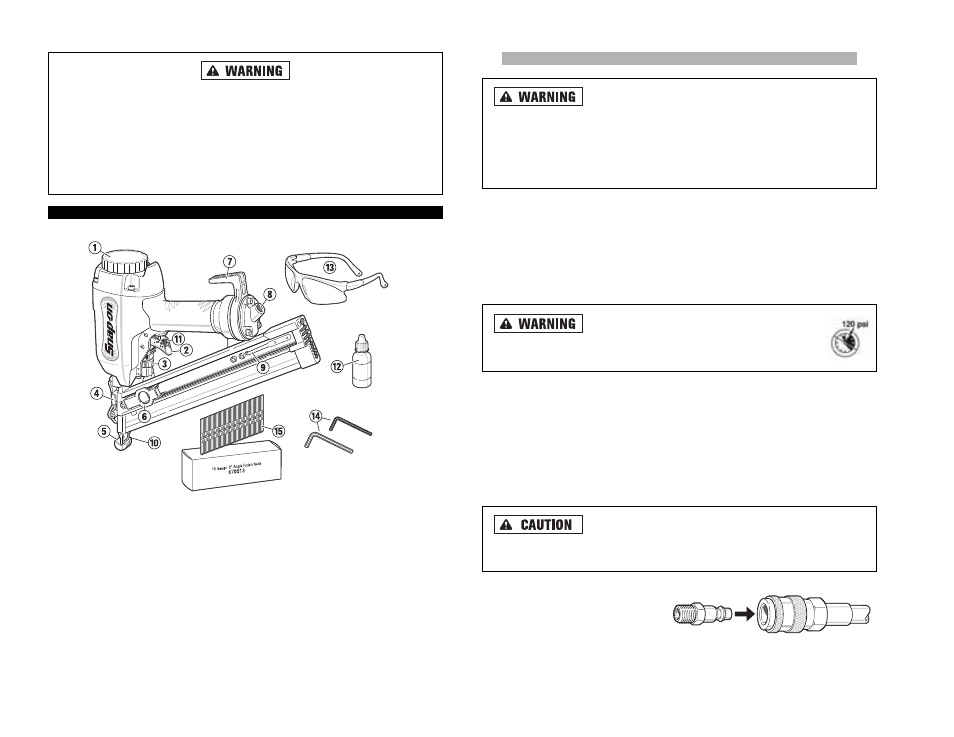

FUNCTIONAL DESCRIPTION

CONTROLS AND COMPONENTS:

1. Exhaust Cover

2. Trigger

3. Nail Depth Adjuster

4. Latch

5. No-mar Nosepiece

6. Pusher

7. Hanging Hook

8. Air Inlet

9. Nail Release

7

10. Work Piece Contact

11. Trigger Actuation Mode Selector

ACCESSORIES:

12. Lubricant

13. Safety Glasses

14. Hex Wrenches (2)

15. Fasteners

8