Spark arrester screen maintenance – Shindaiwa 81714 User Manual

Page 16

16

16

341033

139/150-Hour Maintenance

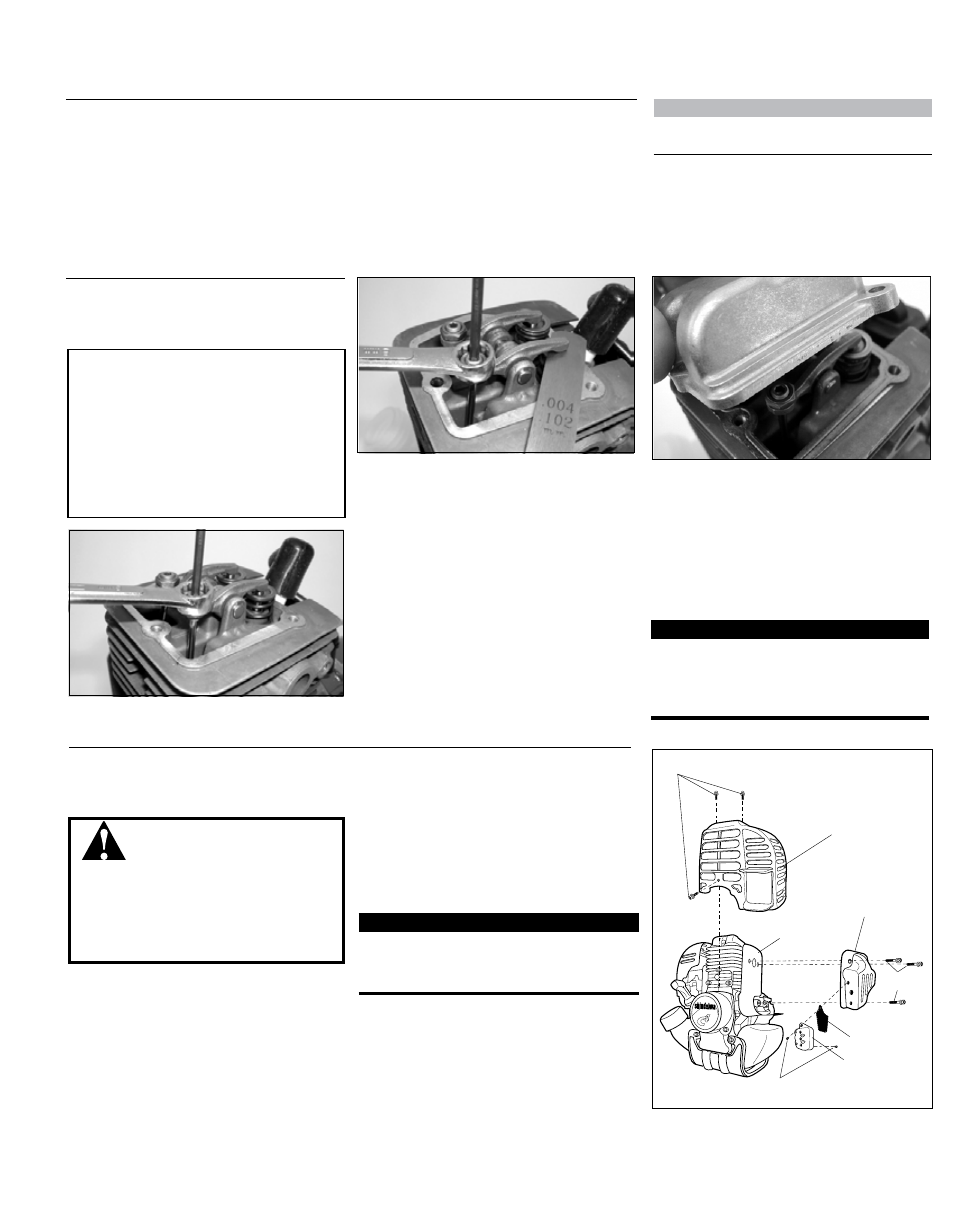

Valve Adjustment

1. Remove cylinder cover, rocker arm

cover, and set piston at TDC-compresion.

. Loosen adjuster locknut so that the .5

mm Allen socket head adjustment screw

can turn freely.

3. Insert .004" (0.10 mm) feeler gauge for

both intake and exhaust between valve

stem tip and rocker arm.

4. Turn adjustment screw (clockwise =

tighter, counter-clockwise = looser) until

feeler gauge is almost snug. Back off

6. Turn engine over several times, and

return to TDC-compression. Recheck

with proper feeler gauge to make sure

clearance adjustment did not change as

a result of tightening locknut. Readjust

as necessary.

7. Replace rocker arm cover gasket to as-

sure proper sealing and install cover.

IMPORTANT!

If new gasket is not available and/or old

gasket is not damaged, old gasket may be

reused. Never use cracked or damaged

gaskets!

CAUTION!

n

Performing a valve adjustment

incorrectly may cause hard starting

and/or can damage the engine.

n

If you are unfamiliar with this engine

or uncomfortable with this proce-

dure, consult with an authorized

Shindaiwa servicing dealer.

just enough to allow gauge to slip out

with limited resistance.

5. While holding adjustment screw in place

with Allen driver, tighten locknut with

wrench.

Maintenance after first 139-hours,

then every 150-hours thereafter.

n

Combustion chamber should be decar-

bonized, and the valve clearance should

be adjusted. It is highly recommended

that this is done by a Shindaiwa-trained

service technician.

n

Replace the spark plug annually: Use

only NGK CMR5H or equivalent resis-

tor type spark plug of the correct heat

range. Set spark plug electrode gap to

0.04-0.08 inch (0.6 -0.7 mm).

Spark Arrester Screen Maintenance

If the engine becomes sluggish and low on

power, check and clean the spark arrester

screen.

Never operate the unit with a damage

or missing muffler or spark arrester!

Operating with a missing or damaged

spark arrester is a fire hazard and

could also damage your hearing.

3. With a small flat bladed screwdriver

remove the screws holding the spark

arrester screen and cover to the muffler.

See Figure 3.

4. Remove the screen and clean it with a

stiff bristle brush.

5. Inspect the cylinder exhaust port for any

carbon buildup.

6. Reassemble the spark arrester, muffler

and engine cover in the reverse order of

disassembly.

IMPORTANT!

If you note excessive carbon buildup, con-

sult with an authorized Shindaiwa servicing

dealer.

WARNING!

1. With a 3 mm hex wrench remove the

3 engine cover screws and the engine

cover. See Figure 3.

. With a 4 mm hex wrench remove the

3 muffler bolts and the muffler. See

Figure 3.

Engine Cover

Screws

Figure 32

Cover

Muffler

Muffler

Gasket

Muffler

Bolts

Spark Arrester

Screen

Spark Arrester

Cover

Cover

Screws

NOTE:

The NGK CMR5H also meets the require-

ments for electro magnetic compliance (EMC).