Setup – Woodstock W1693 User Manual

Page 2

-2-

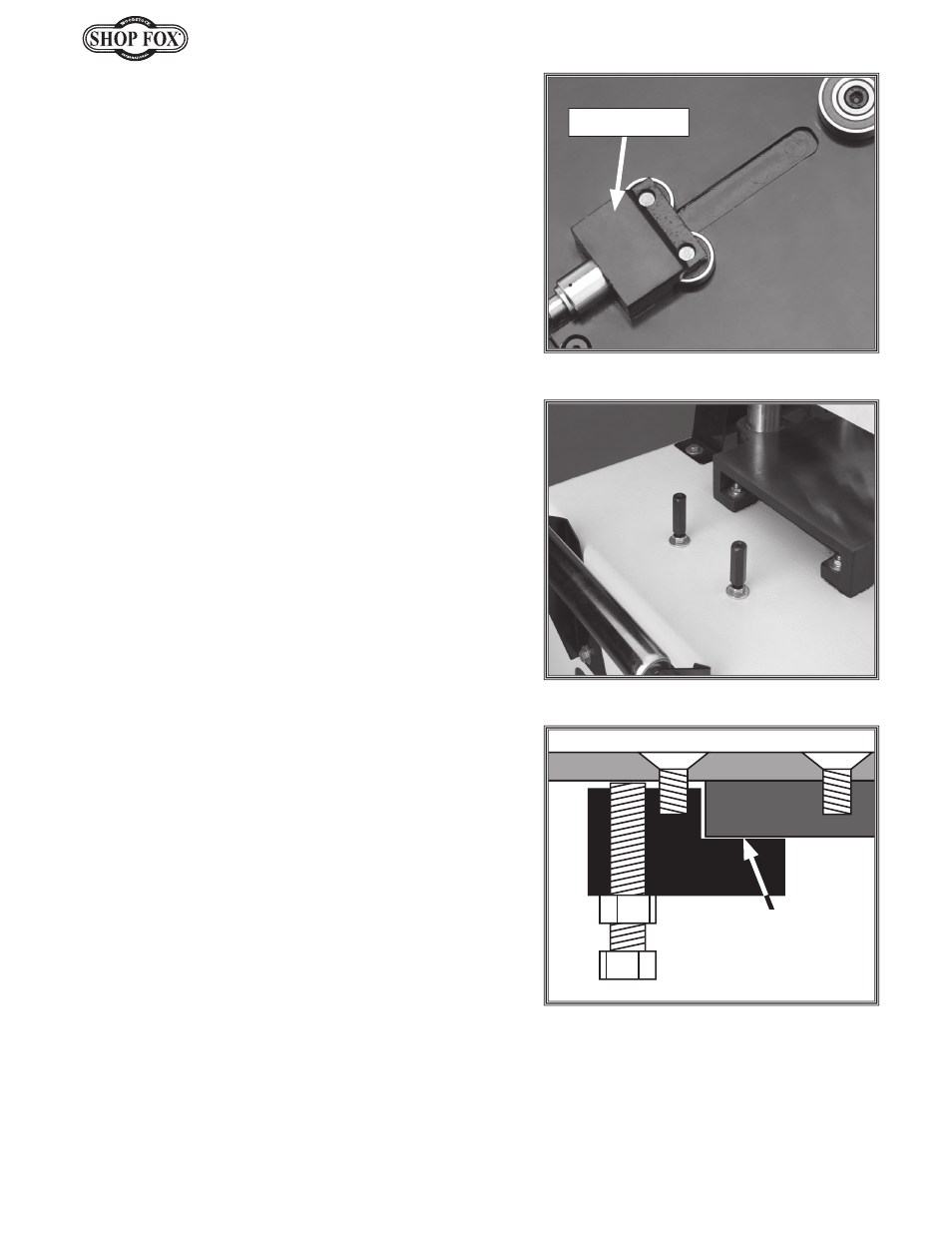

2. Remove the flat head screws securing the vise to the

base plate.

3. Slide the dovetail on the bottom of the vise bearing

block (

Figure 3) into the dovetail groove in the base

plate.

4. Secure the vise to the base plate with the flat head

screws removed in

Step 2.

5. Remove the plugs from the planer/moulder stand.

6. Remove a hex nut and a washer from each of the

base plate support studs.

7. Insert the studs as shown in Figure 4 and loosely

thread the nuts and washers removed in

Step 6 onto

the studs from under the stand.

8. Place the base plate onto the planer/moulder table

and attach it to the studs with the flat head screws.

Note: The studs should be drawn up tight against

the bottom of the base plate.

9. Thread the top hex nuts down against the stand and

tighten the lower hex nuts up against the stand.

10. Loosely attach the mounting clamps to the base

plate with the remaining flat head screws.

11. Adjust the flat head screw and the hex bolts in the

mounting clamp until the mounting clamp is parallel

with the planer/moulder surface (see

Figure 5).

12. Tighten the flat head screws to secure the clamps.

Setup

To prepare for cutting mouldings, do these steps:

1. Build the moulding blank to the desired size and

curve. Make the blank the exact same width as the

moulding blades if the face is profiled, or a maxi-

mum of

1

⁄

8

" wider if the edges are trimmed by the

knives.

2. Build a template out of

3

⁄

4

" MDF that is the exact

width and curve as your moulding. Make the tem-

plate a minimum of 6

1

⁄

2

" longer than the moulding.

This template will guide the moulding through the

planer/moulder.

Figure 3. Support assembly bearing block.

Bearing Block

Figure 4. Base plate support studs.

Figure 5. Mounting clamp attachment.

This surface of the

mounting clamp must be

parallel with the surface

of the planer/moulder.

Mounting

Clamp

Planer/

Moulder

Base Plate