Adjusting blade tension, Blade information – Woodstock W1713 User Manual

Page 19

-17-

W1713 Owner's Manual (Mfg. Since 6/03)

O

PE

R

ATIO

NS

Adjusting Blade Tension

Having proper blade tension is critical to safe cutting

operations that produce good results. Blades that are

tensioned correctly will also last longer and are less likely

to break during the cutting operation. However, finding

the correct amount of tension for each type of blade is

matter of trial-and-error and experience.

If the blade is tensioned too tight, the blade could break

and cause serious personal injury from flying debris. If the

blade is tensioned too loose, the blade will likely fall off

during the cutting operation and cause injury hazards.

Get into the habit of plucking the saw blade like a guitar

string before every use. With time and experience, you

will recognize the distinct sound that indicates the proper

amount of blade tension.

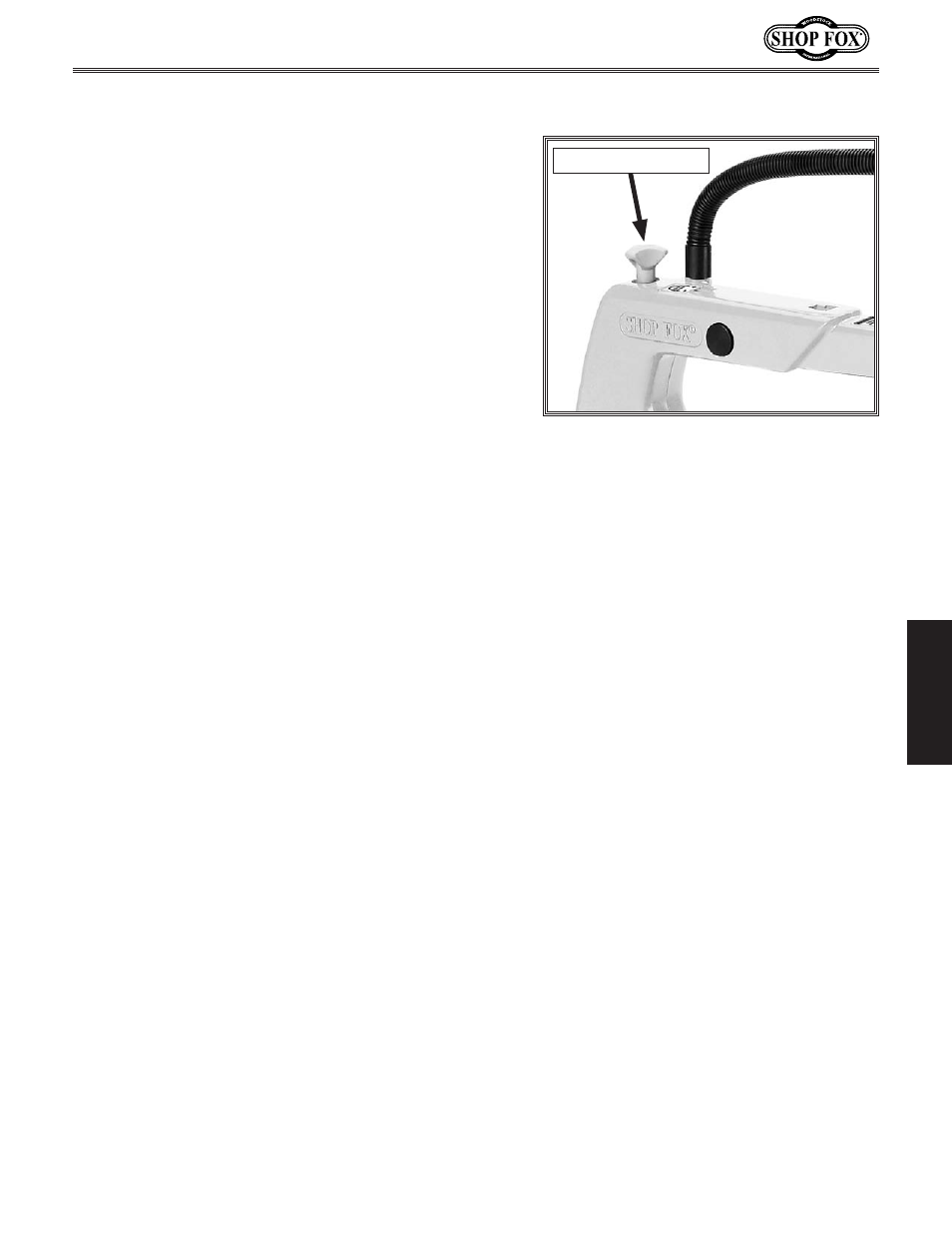

Turn the blade tension knob shown in

Figure 13 clockwise

to increase the blade tension, and counterclockwise to

decrease it.

Figure 13. Blade tension knob.

Blade Tension Knob

Blade Information

Important issues regarding blade performance:

• Typically, a scroll saw blade will stay sharp from

1

⁄

2

to 2 hours of use, depending on how the blade is

used and the type of material being cut.

• Best cutting results will be achieved when cutting

workpieces less than 1" thick.

• When cutting workpieces thicker than 1", move the

workpiece through the blade very slowly.

• Blades will dull quickly when cutting plywood,

hardwoods, and laminates.

• Exerting excessive side pressure on the blade greatly

increases the chance of blade breakage.