Shd-60 troubleshooting, Troubleshooting, General troubleshooting – Stellar Industries V480 User Manual

Page 26: 22 class 4 compressor owner’s manual

22

Class 4 Compressor Owner’s Manual

Troubleshooting

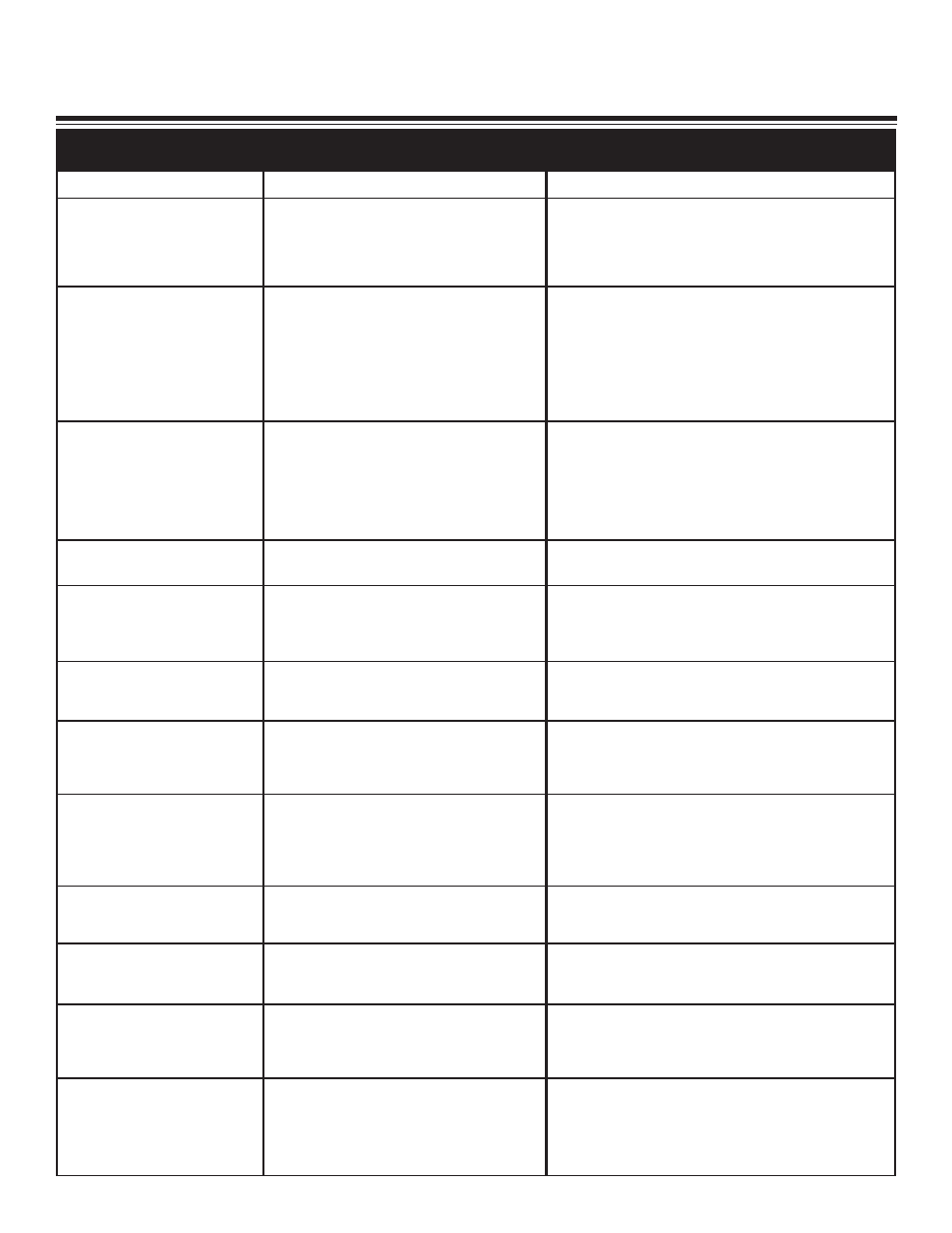

Problem

Compressor runs hot

Compressor does not run

Compressor runs too slow

Compressor will not stop

Air output too low

(air pressure okay)

Compressor cycles

(air not being used)

Air Output low

(Air Pressure Low)

Air pressure too low

Air pressure too high

High crankcase oil usage

Blowing oil from crankcase

breather

No lubricating oil pressure

Possible Cause

Check compressor rotation

Compressor reed valves

Dirty intake filter

Low oil Level

Check valve leaking

No 12 Volt Power to Compressor

Air reservoir full

Hydraulic lines not connected

Couplers or hoses blocked

Air load against compressor

Hydraulic pump not working

Hydraulic motor not working

Check valve leaking

Compressor reed valves

Check for hose leaks

Hydraulic flow too low

Hydraulic motor worn

Power unit relief set too low

Hydraulic system too hot

Speed control not working

Air pressure switch set wrong

Leaking hoses or fittings

Low compressor speed

Air filter dirty

Airlines leaking

Check valve plugged

Leaks in air line

Air pressure switch set wrong

Dirt in solenoid valve

Dirty air filter

Intake reed valves malfunction

Insufficient torque on head bolts

Air pressure switch set wrong

Air line leak

Air consumption exceeds

Compressor capacity

Intake or exhaust valves damaged

Pressure switch not operating

Internal contamination

Pressure switch not adjusted

Oil level too high

Oil leaks

Piston rings worn or broken

Blown head gasket

Piston rings worn or broken

Oil level in crankcase too high

Hole in piston

Air lock in oil pump

No oil in crankcase

Pump suction blocked

Solution

Check fittings on hydraulic motor

Inspect, clean or replace valves

Clean filter assembly

Level Add oil if needed

Disassemble, clean, and re-install

Check Fuse

Drain and activate pressure switch

Connect lines

Locate and remove restriction

Relieve air pressure

Check flow and pressure settings

Inspect and repair

Disassemble, clean, and reinstall or replace

Inspect, clean or replace valves

Tighten any hose fitting leaking

Check and reset flow

Replace with new motor

Readjust relief valve

Reservoir too small. Add cooler to system.

Check power supply and readjust

Check points and setting on switch

Tighten all fittings and hoses

Refer to compressor too slow

Clean or Replace Filters

Retighten hoses

Remove and clean check valve

Tighten hoses and fittings

Check cut-in and cutout settings

Remove and clean

Inspect and clean filter

If air back-flows from air filter, reed valve is faulty and

needs to be replaced.

Tighten bolts to required torque

Readjust high pressure setting

Inspect and tighten loose hoses

Check air demand for items using the air supply

Inspect and replace

Inspect and clean

Inspect and clean

Readjust to lower pressure

Check oil level and drain if needed

Inspect and repair gaskets or seals

Replace rings

Replace gasket

Replace rings

Check oil level and drain

Replace piston

Loosen oil gauge while compressor is running. When

oil begins to flow from fitting, tighten oil gauge.

Check oil level and add

Remove oil intake plug and inspect intake and screen.

Clean blockage.

General Troubleshooting