Maintenance 6 troubleshooting, Maintenance – Simer Pumps 2430 User Manual

Page 6

Maintenance

6

Troubleshooting

For parts or assistance, call Simer Customer Service at

1-800-468-7867 / 1-800-546-7867

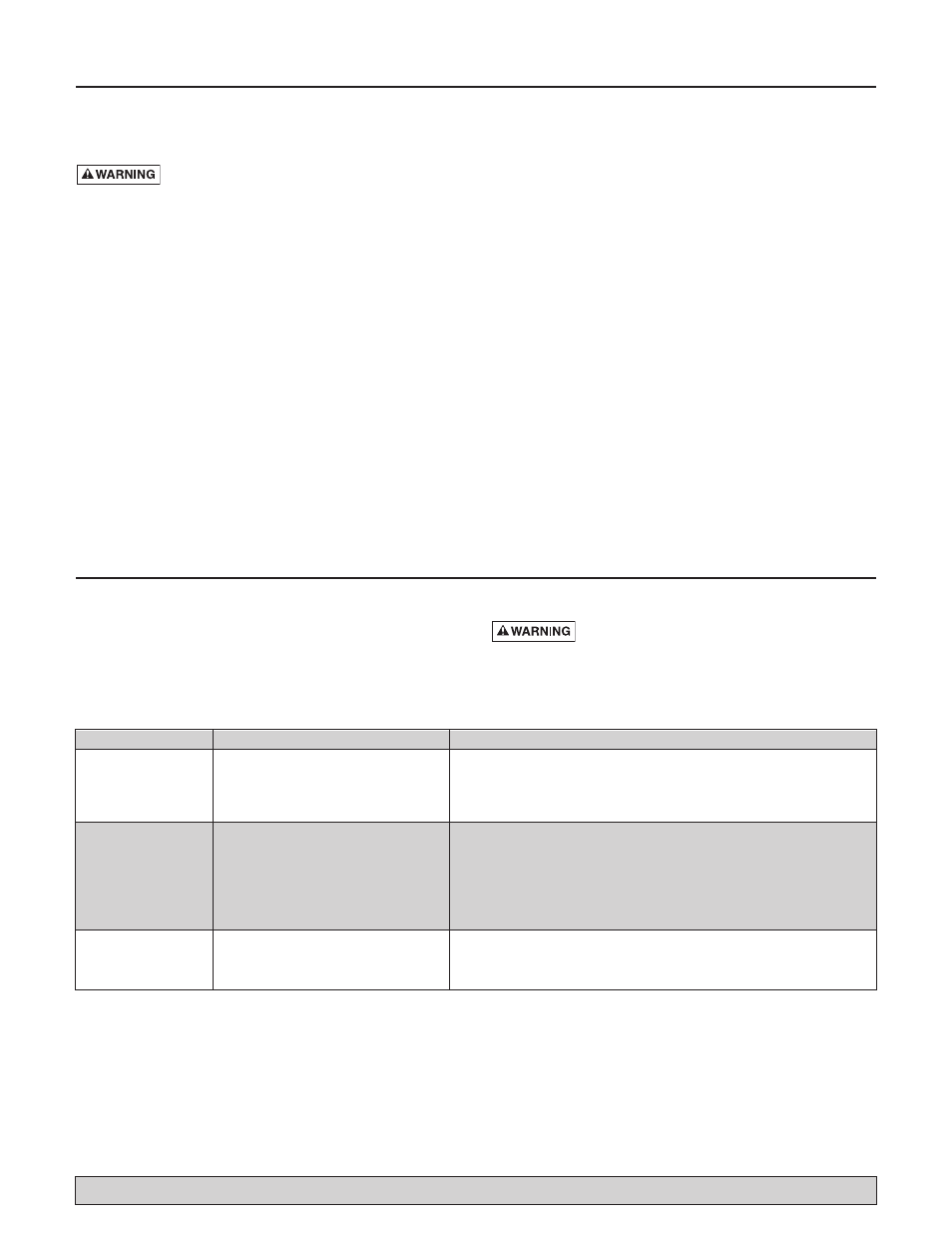

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Pump won’t

Blown fuse or circuit breaker has tripped

If blown, replace with fuse of proper size or reset circuit breaker

start or run

Low line voltage

If voltage under recommended minimum, check size of wiring from main

switch on property. If OK, contact power company or hydro authority

Defective motor

Replace pump

Pump operates but

Low line voltage

If voltage under recommended minimum, check size of wiring from main

delivers little or no

switch on property. If OK, contact power company or hydro authority.

water

Something caught in impeller

Cleanout or replace pump

Worn or defective parts

Replace pump

Check valve installed without

Drill a 1/16" - 1/8" (1.6mm - 3.2mm) dia. hole between pump discharge

vent hole

& check valve. Drilled hole must be located below the waterline.

Intermittent running

Thermal overload has tripped

Protect the installation from the sun

or pump stopped

Pump cooler water

automatically

Pump has run dry; add water

NOTICE: This pump has no serviceable parts inside the

motor housing. Opening the motor housing will ruin the

pump. If obstructions or blockages of the impeller cannot

be cleaned out as described above, or by backflushing

into the discharge with a garden hose, replace the pump.

Hazardous voltage; can shock, burn or kill.

Unplug the pump before attempting to clean or work on

the pump.

MAINTENANCE

Risk of electric shock. Can burn or cause

death. Disconnect the power before servicing, repairing,

or working on pump.

The pump’s motor is completely sealed in the motor

housing and does not require any service. Disassembly

of the motor housing or modification or removal of the

power cord voids the warranty. The power cord is non-

replaceable.

Never run the pump dry! Running the pump dry can

damage the seal, causing leakage. This pump is a sub-

mersible type and must be in water at all times for prop-

er operation and cooling.

Periodically clean the pump inlet. This will avoid

impeller rotation being hampered by any debris.

To Clean Inlet/Impeller

1. Unplug pump.

2. Remove baseplate by turning in direction of OPEN

arrow. Clean out inlet.

3. Remove screw holding volute base to pump housing.

4. Turn volute base in direction of OPEN arrow and

remove. Clean out impeller.

To reinstall, reverse above directions. Be sure to replace

O-Ring and engage volute base tabs with pump housing

before replacing screw.