Principles of operation system layout, Important – SeaLand VACUUM HOLDING TANK User Manual

Page 3

3

The Vacuum Holding Tank (VHT) system can be installed

on most boats that presently use a portable, manual or

electric toilet. The following procedure will be helpful:

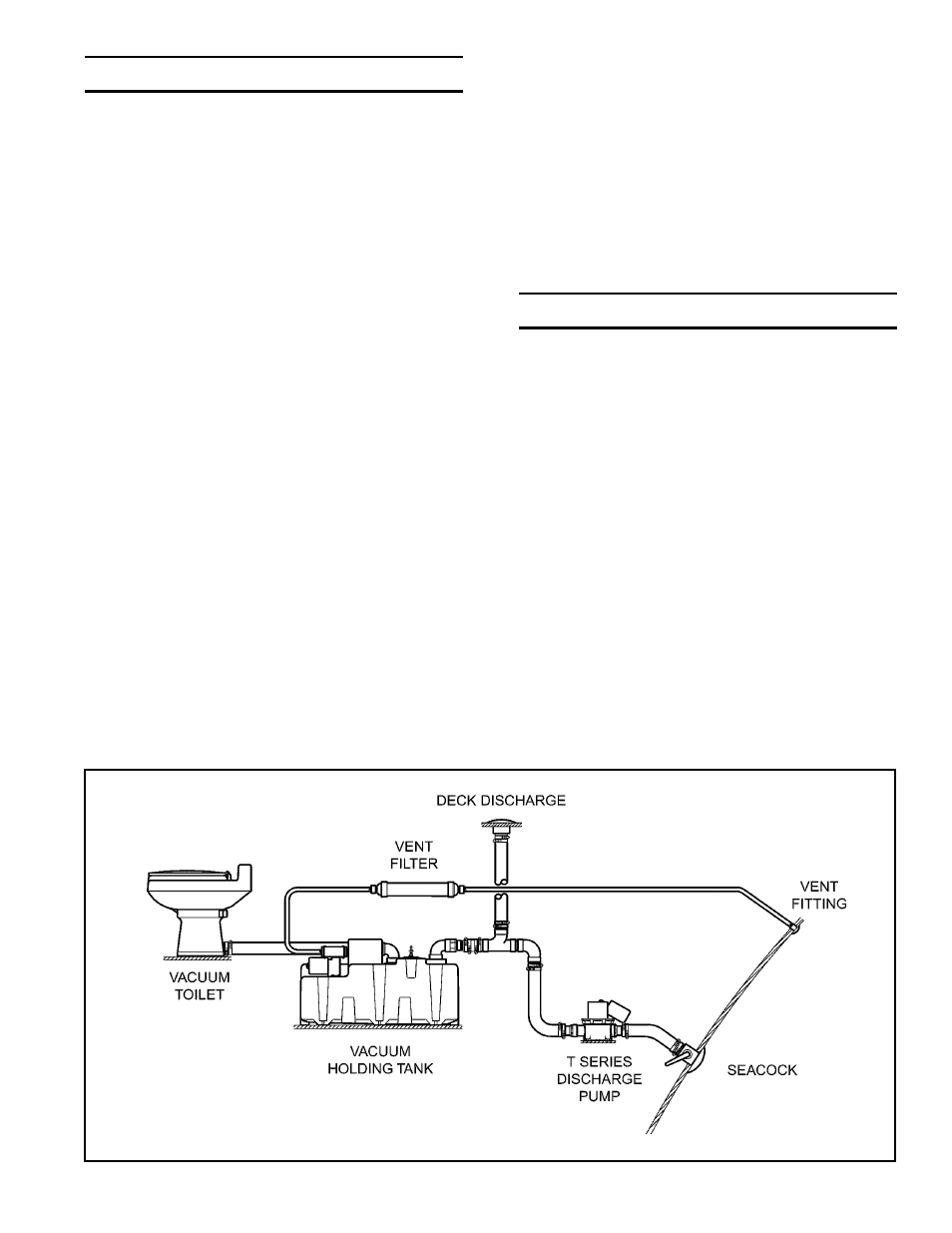

1. Review the typical system layout to get a general

idea of how the system will operate and what discharge

options will be considered (see Figure 1).

2. Draw or obtain a layout of the boat which allows the

location of head compartments, bulkheads, engine space,

tanks, through-hull fittings, etc. This layout should include

top views and side views and show relative distances

and heights with reasonable accuracy.

3. Use the information in the Component Locating

Procedure section to help select the best locations for

your boat layout.

4. Routing of vacuum hose should be considered when

selecting a location for the toilet and the (VHT). A

maximum of 20 feet (6.1 m) of hose can be used be-

tween the toilet and the VHT.

5. Before starting the actual installation, carefully re-

view the Key Installation Points.

VacuFlush systems use a small amount of water (one

pint to one quart) and the vacuum that is generated by

the vacuum pump to flush. Each toilet must be con-

nected to a pressurized water system. Fresh water is

recommended and will result in an odor-free bathroom.

If seawater is used, the water should be filtered.

No complicated user instructions are required. Lifting the

flush lever adds water to the bowl. Pressing the flush

lever (or pulling the flush lever on a 106 toilet) opens a

mechanical seal that allows the vacuum force to pull the

waste from the bowl as clean water rinses the bowl. The

vacuum moves the waste (at approximately 7 feet [2.1

m] per second) through a one-inch opening in the toilet

base. Incoming air fragments the waste as it passes

through the base opening. This process eliminates the

need for macerators or mechanical motors in the toilet

base.

Next, the waste is transferred into the Vacuum Holding

Tank (VHT). System vacuum is monitored by a vacuum

switch that is located on the outside of the VHT. When

the switch senses a drop in vacuum in the system, it

automatically signals the pump to energize and bring

the vacuum back to operating level. This process is nor-

mally completed in about one minute.

In a properly operating system, the stored vacuum will

“leak” down between flushes, causing the vacuum pump

to run for a short period. The pump should not run more

than once every three (3) hours after the last flush.

An “On-Off” night switch can be installed to silence the

vacuum pump during sleeping hours. The VacuFlush

Status Panel, an optional accessory, features an inte-

gral circuit breaker that provides a convenient night

switch.

IMPORTANT:

Before pumping out the VHT, it

is recommended that the power to the system be

turned off. Then, flush the toilet. This releases the

stored vacuum in the tank, thus, allowing the

dockside pump to empty the waste out more easily.

If the dockside pump has low suction capability,

you may need to flush the toilet a second time

during the pump out.

The Vacuum Relief Valve (VRV) will automatically open

at 13" of vacuum and is spring loaded to close at 11" of

vacuum to prevent leaking during normal operation.

Figure 1

PRINCIPLES OF OPERATION

SYSTEM LAYOUT