Maintenance – Jet Tools VBS-3612 User Manual

Page 22

22

Maintenance

Before doing maintenance on

the machine, disconnect it from the electrical

supply by pulling out the plug or switching

off the main switch! Failure to comply may

cause serious injury.

Use a brush to loosen accumulated chips and

debris. Use a shop vacuum to remove the

debris. Make sure the chip brush on the lower

band wheel is properly adjusted.

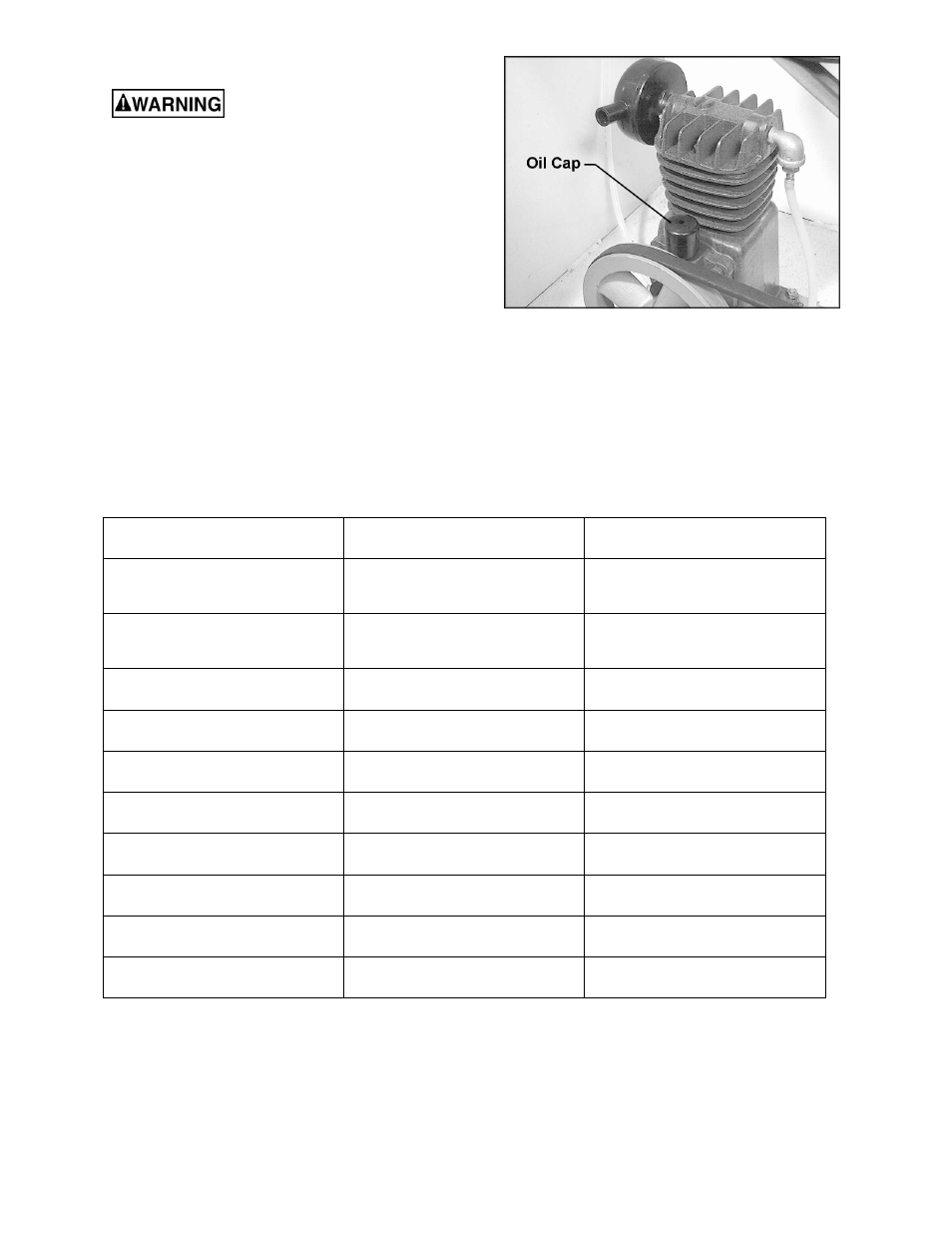

Lubricate the air compressor with air tool oil

about every six months, or more frequently if

necessary. Unscrew the cap (Figure 26) and

add oil. Replace cap when finished.

Add grease to the gear box through the grease

fitting; also add grease as needed to the worm

gear.

If the power cord is worn, cut, or damaged in

any way, have it replaced immediately.

Figure 26

The chart (Figure 27) identifies areas that

require cleaning and/or lubricating. Use good

quality, general purpose lubricants.

Machine Part

Lubricant

Frequency

Bearings

Machine

oil

Wipe down every day and

lubricate every 6 months

Rack and sliding portion of

Guide Post

Grease

every 7 days

Gear shift lever

Grease

every 6 months

Worm gear

Grease

every 3 months

Variator pulley

Machine oil

every 3 months

Blade tension screw

Grease

once a month

Air compressor reservoir

Air Tool oil

every 6 months

Weld clamp jaws

-------

clean after each use

Rubber tire

-------

wipe off daily

Work tables

-------

clean daily

Figure 27