Troubleshooting – Jet Tools JWL-1642EVS-2 User Manual

Page 22

22

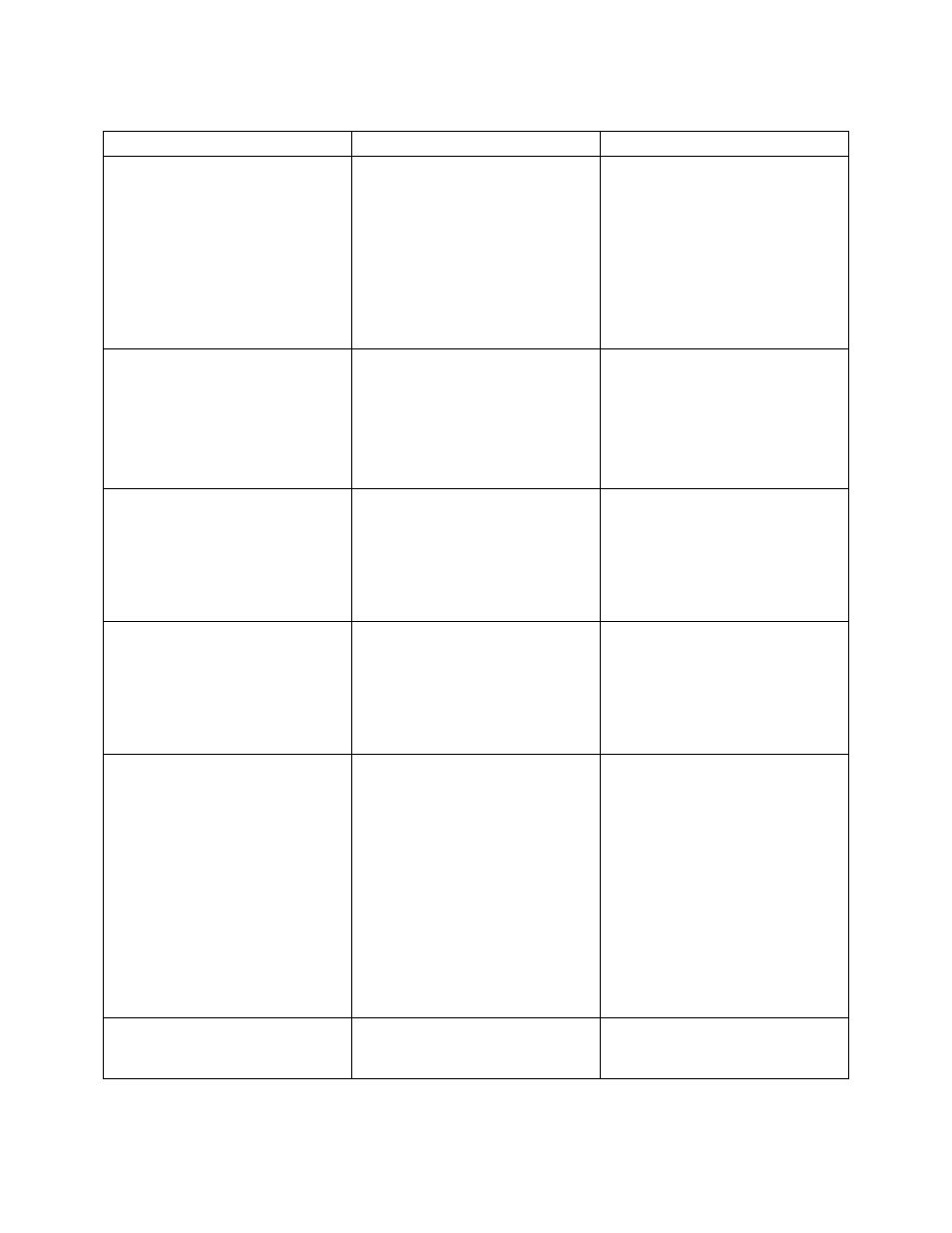

Troubleshooting

Problem Possible

Cause Solution

Excessive vibration.

1. Workpiece warped, out of

round, has major flaw, or was

improperly prepared for

turning

2. Worn spindle bearings

3. Worn

belt

4. Motor mount bolt or handle

loose

5. Lathe on uneven surface

1. Correct problem by planing,

bandsawing, or scrap the

workpiece all together

2. Replace

bearings

3. Replace

belt

4. Tighten bolt or handle

5. Shim lathe bed, or adjust feet

on stand

Motor or spindle stalls or will not

start

1. Excessive

cut

2. Worn

motor

3. Broken

belt

4. Worn spindle bearings

5. Improper cooling on motor

1. Reduce cut depth

2. Replace

motor

3. Replace

belt

4. Replace

bearings

5. Clean sawdust from motor

fan

Motor fails to develop full power.

1. Power line overloaded

2. Undersize wires in supply

system

3. Low

voltage

4. Worn

motor

1. Correct overload condition

2. Increase supply wire size

3. Request voltage check from

power company and correct

low voltage condition

4. Replace

motor

Tools tend to grab or dig in.

1. Dull

tools

2. Tool support set too low

3. Tool support set too far from

workpiece

4. Improper tool being used

1. Sharpen

tools

2. Reposition tool support

height

3. Reposition tool support

closer to workpiece

4. Use correct tool for operation

Tailstock moves when applying

pressure

1. Excessive pressure being

applied by tailstock. Note:

The screw action of the

tailstock is capable of

applying excessive pressure

to workpiece and headstock.

Apply only sufficient force by

tailstock to hold workpiece

securely in place. Excessive

pressure can cause damage

to machine.

2. Lathe bed and tailstock

mating surfaces are greasy

or oily.

1. Slide tailstock down to the

right side of the lathe against

the stop. Move headstock

into position and apply

pressure to workpiece with

tailstock.

2. Remove and clean surfaces

with a cleaner degreaser

Digital readout does not work

1. Digital readout sensor out of

position

1. Open the belt access and

position the sensor so that it

reads the bolts