Jet Tools 22-44 Plus User Manual

Page 8

8

Assembly and Setup

If you purchased the optional Performax 22-44

Plus Stand refer its assembly instructions before

proceeding with the drum and conveyor

assembly.

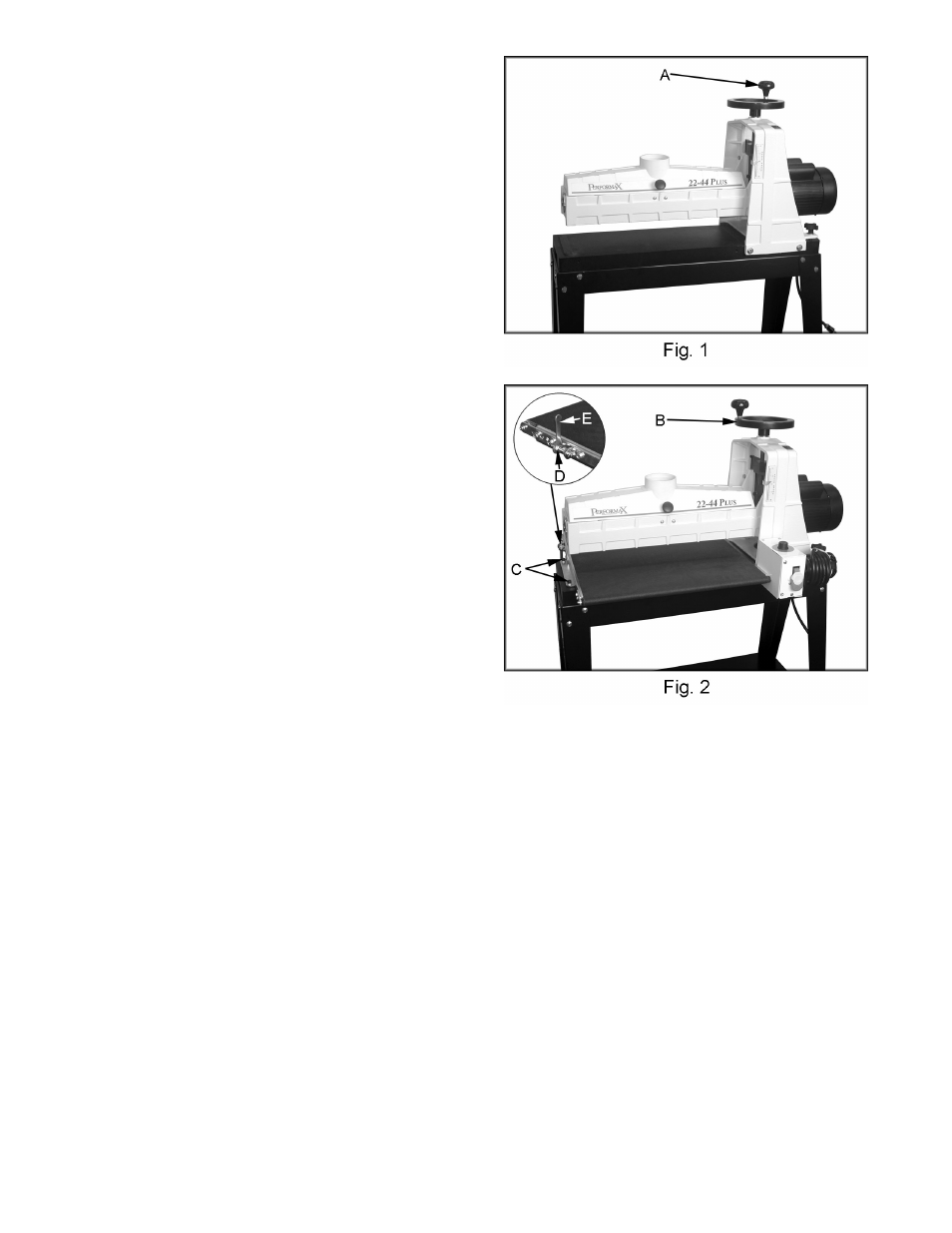

1. Attach the knob (A, Fig. 1) to the handwheel

and tighten with a 9/16” wrench.

2. Place the conveyor upside down on a table

surface.

3. Raise the drum by turning handwheel (B,

Fig. 2) clockwise.

4. Align four holes in the conveyor with the four

holes in the base of drum assembly.

5. Secure conveyor in place with four 5/16”-18

x 3/4” socket head cap screws (C, Fig. 2),

four 5/16” lock washers and four 5/16” flat

washers.

6. Plug motor cord into the control box

receptacle.

Drum Height Control

Drum height is controlled by the height

adjustment handle (B, Fig. 2). Turning

handwheel in a counter-clockwise direction

lowers the drum.

Turning height adjustment handwheel one

revolution lowers the drum approximately 1/16”.

Conveyor Belt Tension

Conveyor belt tension adjustment may be

necessary during break in period to compensate

for belt stretching.

If conveyor belt can be stopped by hand

pressure applied directly to the top of conveyor

bed, the belt is too loose. Insufficient belt

tension will cause slippage of conveyor belt on

the drive roller during sanding operation.

Excessive belt tension can result in bent rollers,

bent take-up brackets and premature conveyor

belt wear.

After the PowerFeed unit has been installed

adjust the hex nuts (D, Fig. 2) on both sides of

the conveyor to obtain a tight, and equally

tensioned conveyor belt. Use the attached

wrench (E, Fig. 2) to adjust the hex nuts.