Jet Tools 22-44 Plus User Manual

Page 10

10

Fine Tuning Drum Alignment

When sanding boards wider then the drum,

drum alignment is critical and must be adjusted

exactly level to slightly high on the outboard end.

This should prevent any ridges from developing

in the stock. Always test on scrap wood before

sanding workpiece.

Run a piece of scrap wood approximately 6”

wide by 30” - 40“ through the sander sideways

so that the end of board extends past the end of

drum.

Turn board 180 degrees and sand the same

side of the workpiece without changing the

sanding height.

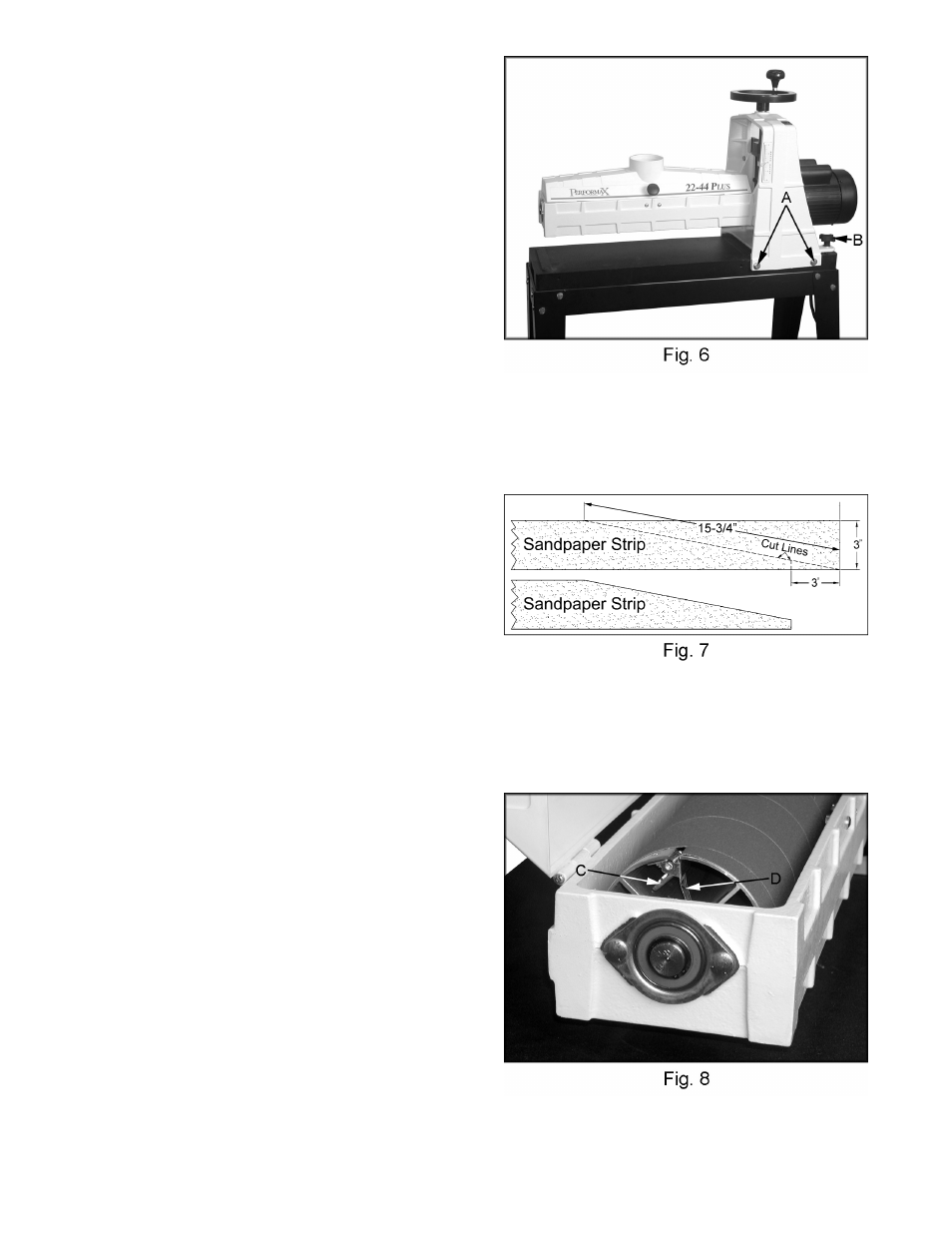

If a ridge is visible due to drum overlap loosen

the four hex cap bolts (A, Fig. 6) and turn the

adjusting knob (B, Fig. 6) slightly. Turn the

adjusting knob clockwise to raise the outboard

end of the drum. Tighten the four hex cap bolts.

Repeat process until ridge is gone and the entire

workpiece is sanded.

Wrapping Abrasive Strips

Note: When using Performax “Ready to Wrap”

and “Ready to Cut” abrasives, not all of the

steps below are necessary. You can use the

original abrasive belt that comes with the sander

as a template for cutting your own strips.

1. Mark and cut a taper at one end of the roll,

see Figure 7.

2. Square off the end of taper, see Figure 7.

3. Raise fastener lever (C, Fig. 8) on the

outboard end of drum, and insert the

tapered end of the abrasive (D, Fig. 8) so

that it uses most of the width of the slot.

Then release the clip lever to securely hold

the strip end to the fastener.

4. The square edge of the abrasive strip should

follow the edge of the drum, see Figure 8.