Mode selector switch and cal function, Tandem operation: ggx master with ggx slaves – Johnson Controls M9220-GGX-3 User Manual

Page 9

M9220-GGx-3 Proportional Electric Spring Return Actuators Installation Instructions

9

Mode Selector Switch and CAL Function

The M9220-GGx-3 Proportional Electric Spring Return

Actuators are factory set at Direct Acting (DA), DC 0 to

10 V control input (Figure 13). To change to RA

operation, move the mode selection switch from DA to

RA. The DC input signal is selectable from

DC 0 to 10 V or from DC 2 to 10 V, which corresponds

to 0 to 90° rotation. If the rotation range is reduced, the

end-stop is reached with a reduced input signal. For

example, if a DC 0 to 10 V input signal is selected and

the rotation range is limited to 75°, the end-stop is

reached at DC 8.3 V. If an external 500 ohm resistor is

placed across the input (see Figure 10), the switch

positions then select between 0-20 mA or 4-20 mA.

The CAL function enables the actuator to redefine the

selected control input range proportionally across a

reduced rotation range. The actuator stores the

reduced rotation range in nonvolatile memory (retains

data when power is lost or removed).

To calibrate the control input range, proceed as follows:

1.

With power off, move the mode selection switch to

the CAL position (Figure 13). Then, energize the

actuator. The actuator automatically rotates until

the end-stops are found, and proportionally

reconfigures the control input range to the reduced

rotation range.

2.

Return the mode selection switch to the desired

selection (example: DA, 0 to 10 VDC control input).

Note: During normal operation, if the actuator

stroke increases due to seal or seat wear, the input

is redefined to the increased rotation range in

approximately 0.5° increments.

3.

If the actuator mounting position is changed or if

the linkage is adjusted, repeat Steps 1 and 2 to

reinitiate the CAL function.

Note: To repeat calibration with power applied, move

the mode selection switch out of the CAL position for at

least 2 seconds before returning it to the CAL position.

Auto calibration begins 5 seconds after you return it to

the CAL position.

Tandem Operation: GGx Master with

GGx Slaves

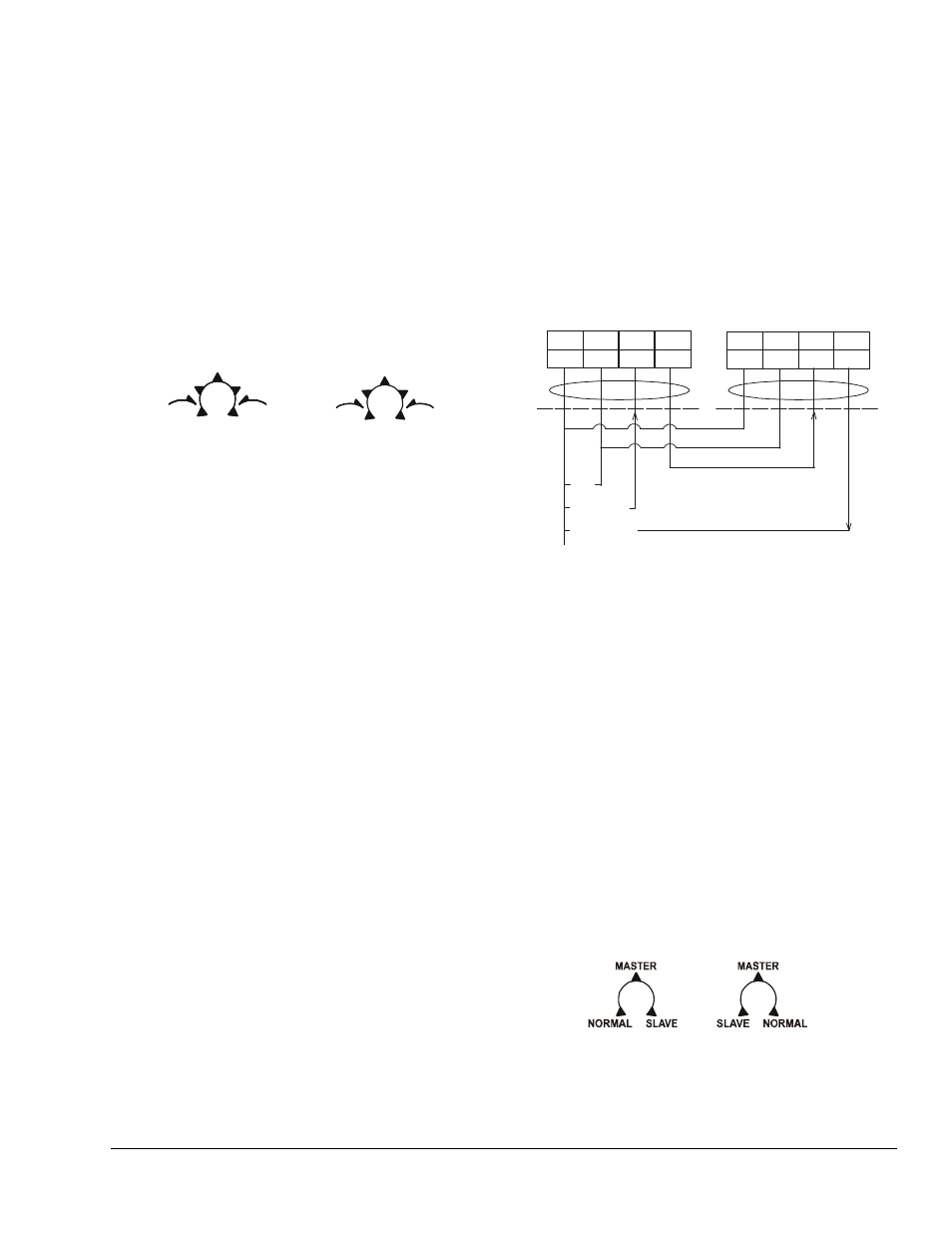

The tandem configuration (Figure 14 and Figure 16)

provides twice (with two actuators) or triple (with three

actuators) the running and spring return torque of a

single actuator, or 354 lb·in (40 N·m), 531 lb·in

(60 N·m). The actuators may be mounted in tandem

using the M9000-158 Tandem Mounting Kit. To mount

a third actuator, user-configured bracketing is required.

Follow these guidelines for tandem operation:

•

Two or three M9220-GGx-3 actuators may be

operated in tandem on the same shaft. If mounting

two actuators, see Figure 14; for three actuators,

see Figure 16.

•

Each actuator requires separate 24 volt power.

When two or more actuators connected in tandem

share a common power source, the total maximum

power draw is actually 1.5 times the normal

running current for each actuator.

(Total Power = Number of Actuators x Running

Power x 1.5).

•

Only one of the actuators can be configured as the

master. Set the selector switch to the master

position (Figure 15).

Figure 13: Mode Selection

modes

el

Side A of Actuator

Side B of Actuator

RA

DA

DA

2-10

0-10

0-10

2-10

+

+

CAL

2-10

0-10

0-10

2-10

+

+

CAL

2-10

0-10

0-10

2-10

+

+

CAL

RA

Figure 14: Tandem Connection

F

IG

:t

an

d

em

1

Master

(M9220GGx actuator)

DC 0(2)...10V Control with Tandem Connection

Slave

(

only)

M9220GGx actuator

Y

DC 0(2)...10 V

+

U

+

1

2

3

4

BLK RED GRY ORN

AC/DC

24 v

~(+)

DC 0(2)...10 V

COM

+

1

2

3

4

BLK RED GRY ORN

se

le

c

t

Side A of Actuator

Side B of Actuator

Figure 15: Tandem Selector Switch