Electrial connection, Gas connection – Indesit KD3G11S/G User Manual

Page 4

4

GB

Electrial connection

Electric cookers come without a power supply cable.

The cooker is designed to operate on an electricity

supply which conforms to the electrical data shown

on the Rating Plate. The cooker can be connected to

the mains only after removing the back panel of the

cooker itself with a screwdriver.

! the following installation procedure must be carried

out by a qualified electrician. The electrical

installation must comply with the IEE Regulations,

Building & local By-Lays.

For the installation of the feeding cable carry out the

following operations:

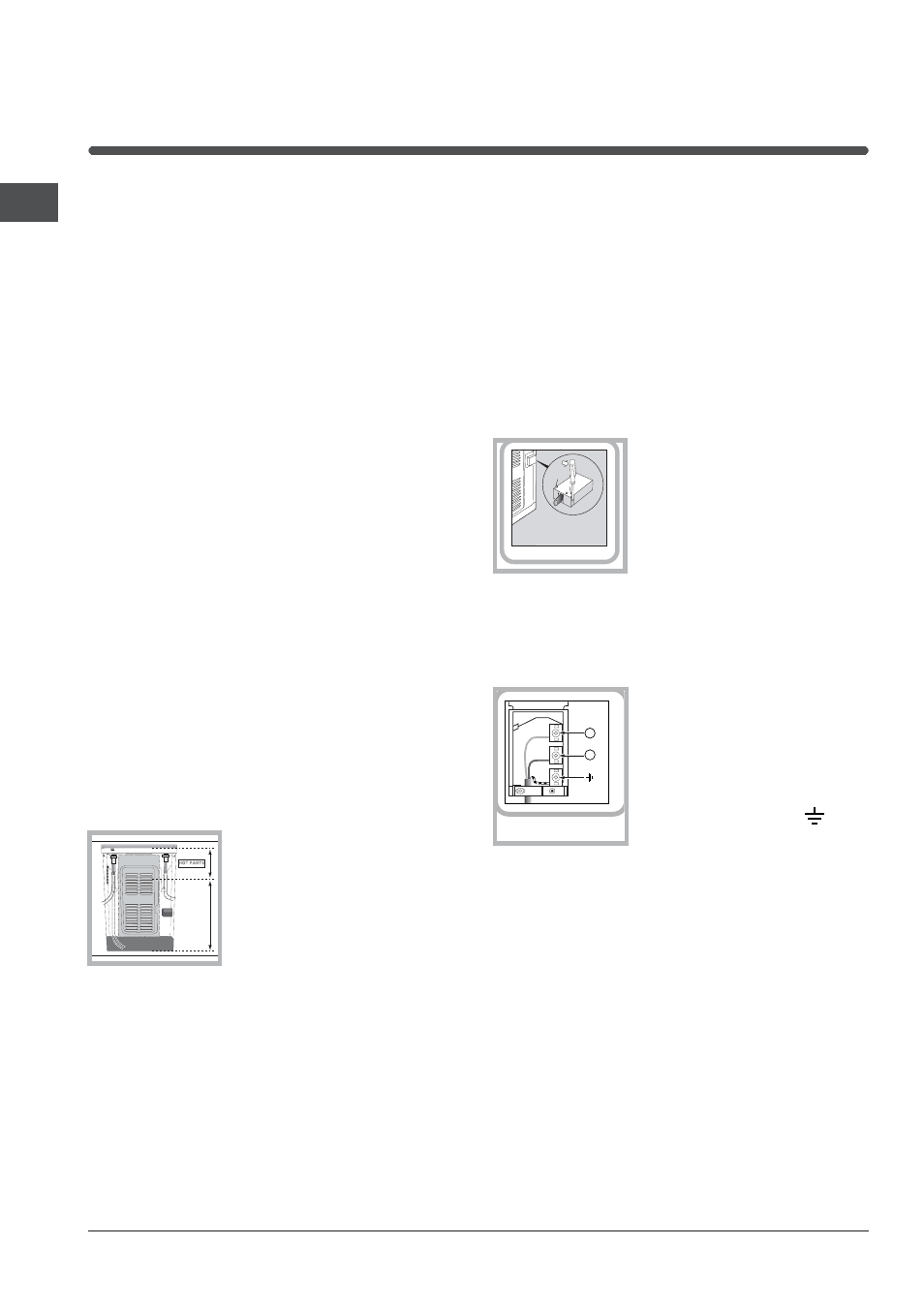

Using a screwdriver, prise

on the side tabs of the

terminal board cover (see fig.

A);

Pull and open the junction

blok lid

! The wires in the mains lead are coloured in

accordance with the following code:

Green & Yellow

Earth

Blue

Neutral

Brown

Live

As the colours of the wires in

the mains lead may not

correspond with the coloured

markings identifying the

terminals in your plug,

proceed as follows:

Green & Yellow wire to

terminal marked E or

or

coloured Green or Green &

Yellow.

Brown wire to terminal marked L or coloured Red.

Blue wire to terminal marked N or coloured Black

(see fig. B).

fix the feeding cable in the special cable stop and

close the cover.

! The power supply cable must have these minimum

requirements:

Type: H05RR-F

Section: 3x1.5 mm

2

Ensure that the mains cable is routed away from any

brackets affixed to the rear panel and is not trapped

to the rear wall when pushing the cooker into

position between cabinets.

Gas connection

The cooker should be connected to the gas-supply

by a corgi registered installer. During installation of

this product it is essential to fit an approved gas tap

to isolate the supply from the appliance for the

convenience of any subsequent removal or

servicing. Connection of the appliance to the gas

mains or liquid gas must be carried out according to

the prescribed regulation in force, and only after it is

ascertained that it is adaptable to the type of gas to

be used. If not, follow the instructions indicated in

the paragraph headed Adaptation to different gas

types. On some models the gas supply can be

connected on the left or on the right, as necessary;

to change the connection, reverse the position of the

hose holder with that of the cap and replace the

gasket (supplied with the appliance). In the case of

connection to liquid gas, by tank, use pressure

regulators that conform to the regulation in force. The

gas supply must be connected to the left of the

appliance. Be sure that the hose does not pass

through the rear of the cooker touching hot parts.

! make sure the supply pressure conforms with

the values shown in the table entitled

Caracteristics of the burners and nozzles.

When the cooker is installed between cabinets

(recessed), the gas connection must be effected

by an approved flexible hose with bayonet fitting

(BS 669 Current Edition). The gas inlet for the

cookers is a threaded G 1/2 gas female fitting.

Connecting the gas supply

To make the connection, a

flexible hose should be used

corresponding to the current

gas regulations which are:

the hose must never be at

any point in its lenght in

contact with the hot parts of

the cooker;

the hose must never be longer than 1,5 metre;

the hose must not be subject to any tension or

torsional stress and it must not have any

excessively narrow curves or bottlenecks;

the hose must be easy to inspect along its entire

length to check its condition;

the hose must always be in good condition, never

attempt to repair.

! the installation must comply with gas safety

(installation and use) regulations 1984. In all cases

for the above, by low, a qualified, corgi approved

engineer must be called for installation.

HOT PARTS

600 mm

Fig. A

4

2

N

Fig. B

L