Ingersoll-Rand 4578217 User Manual

Page 16

16

MAINTENANCE SECTION

ASSEMBLY

General Instructions

1. Always press on the inner ring of a ball--type bearing

when installing the bearing on a shaft.

2. Always press on the outer ring of a ball--type bearing

when pressing the bearing into a bearing recess.

3. Whenever grasping a tool or part in a vise, always use

leather--covered or copper--covered vise jaws. Take

extra care not to damage threads or distort housings.

4. Always clean every part and wipe every part with a

thin film of oil before installation.

5. Check every bearing for roughness. If an open

bearing must be cleaned, wash it thoroughly in clean

solution and dry with a clean cloth. Sealed or

shielded bearings should not be cleaned. Work

grease into every open bearing before installation.

6. Apply a film of O--Ring lubricant to every O--Ring

before installation.

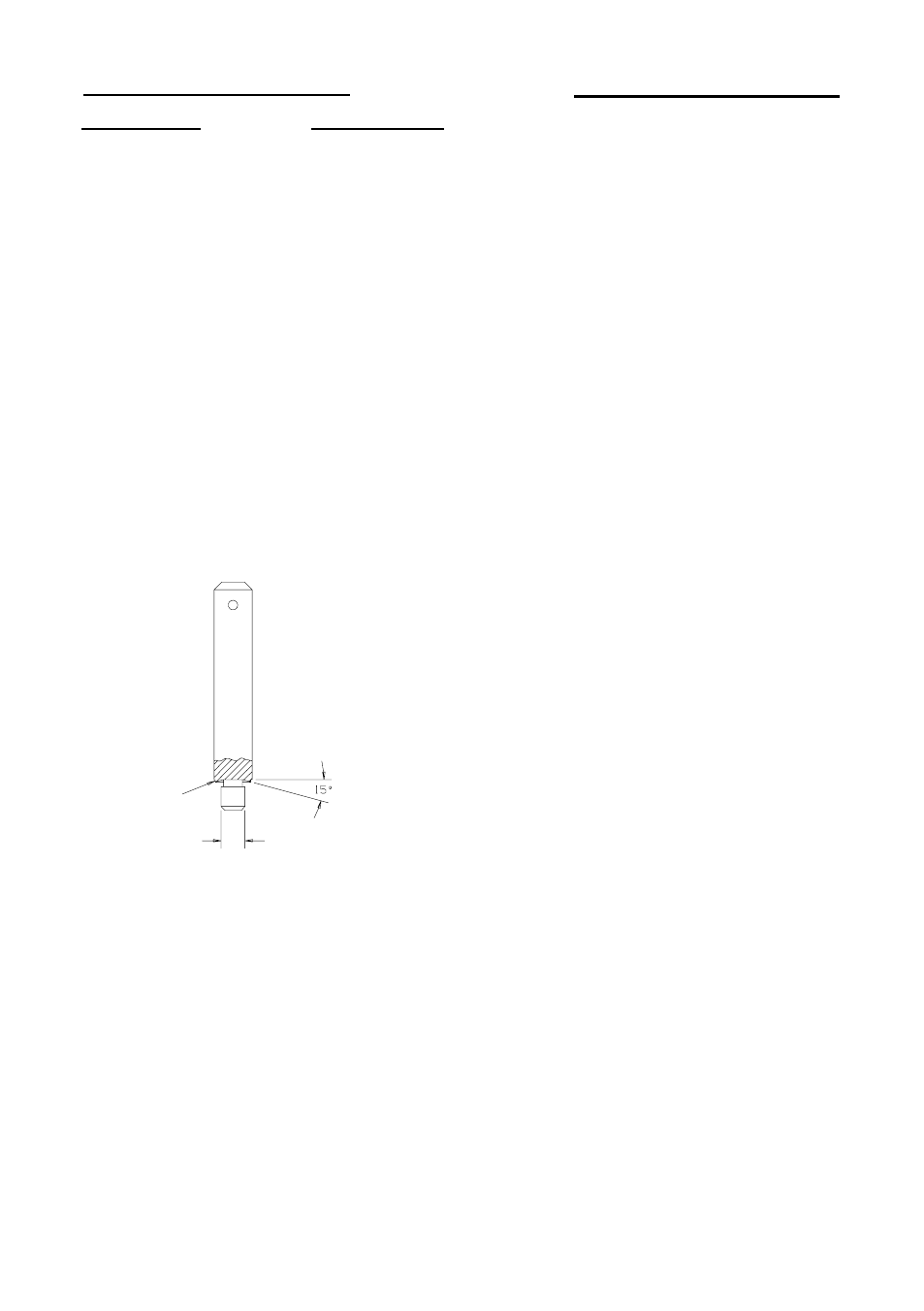

7. Unless otherwise noted, always press on the stamped

end of a needle bearing when installing a needle

bearing into a recess. Use a bearing inserting tool

similar to the one shown in Dwg. TPD786.

Needle Bearing Inserting Tool

SHOULDER TO

REGULATE DEPTH

PILOT TO FIT I.D. OF

BEARING.

LENGTH OF PILOT TO BE

APPROXIMATELY 1/8”

LESS THAN LENGTH OF

BEARING

(Dwg. TPD786)

Tool Specific Instructions:

1. Assembly sequence is the reverse of disassembly.

2. First install the Throttle Lever Assembly, then the

Valve parts.

3. Place the O--Ring Gasket and Muffler Element in

position on the back of the Motor Housing and slide

the Composite Housing down over the Motor

Housing. Make sure the Gasket stays in correct

position so as to not get pinched by the Composite

Housing. Push the Composite Housing all the way

back.

4. Install the Inlet parts. Make sure the O--Ring stays in

correct position so as to not get pinched by the Inlet

Bushing.

5. Assemble the Motor and install it in the Motor

Housing. Make sure the Cylinder Dowel (24) is

aligned with the round hole in the Motor Housing.

6. Install the Motor Clamp (SC models only), or

Coupler, Clamp Sleeve and Extension assembly (XC

models only).

7. Install the Housing Cap and the Collet parts.