Mt-86d — operation – Multiquip Tamping Rammer Mikasa MT-86D User Manual

Page 12

PAGE 12 — MT-86D — PARTS & OPERATION MANUAL — REV. #1 (08/19/04)

1. Definition of Tamping Rammer

The Mikasa MT-86D diesel rammer is a powerful compacting

tool capable of applying tremendous force in consecutive

impacts to a soil surface. The impact force of the MT-86D levels

and uniformly compacts voids between soil particles to increase

dry density. Its applications include soil compacting for road,

embankment and reservoirs as well as backfilling for gas

pipelines, water pipelines and cable installation work.

2. Construction of Tamping Rammer

The rammer is equipped with an air-cooled, four-stroke diesel

engine. Transmission of the power takes place by increasing

engine speed to engage a centrifugal clutch. Circular motion is

converted into vertical motion to create impact force.

3-2. Preparation Inspection:

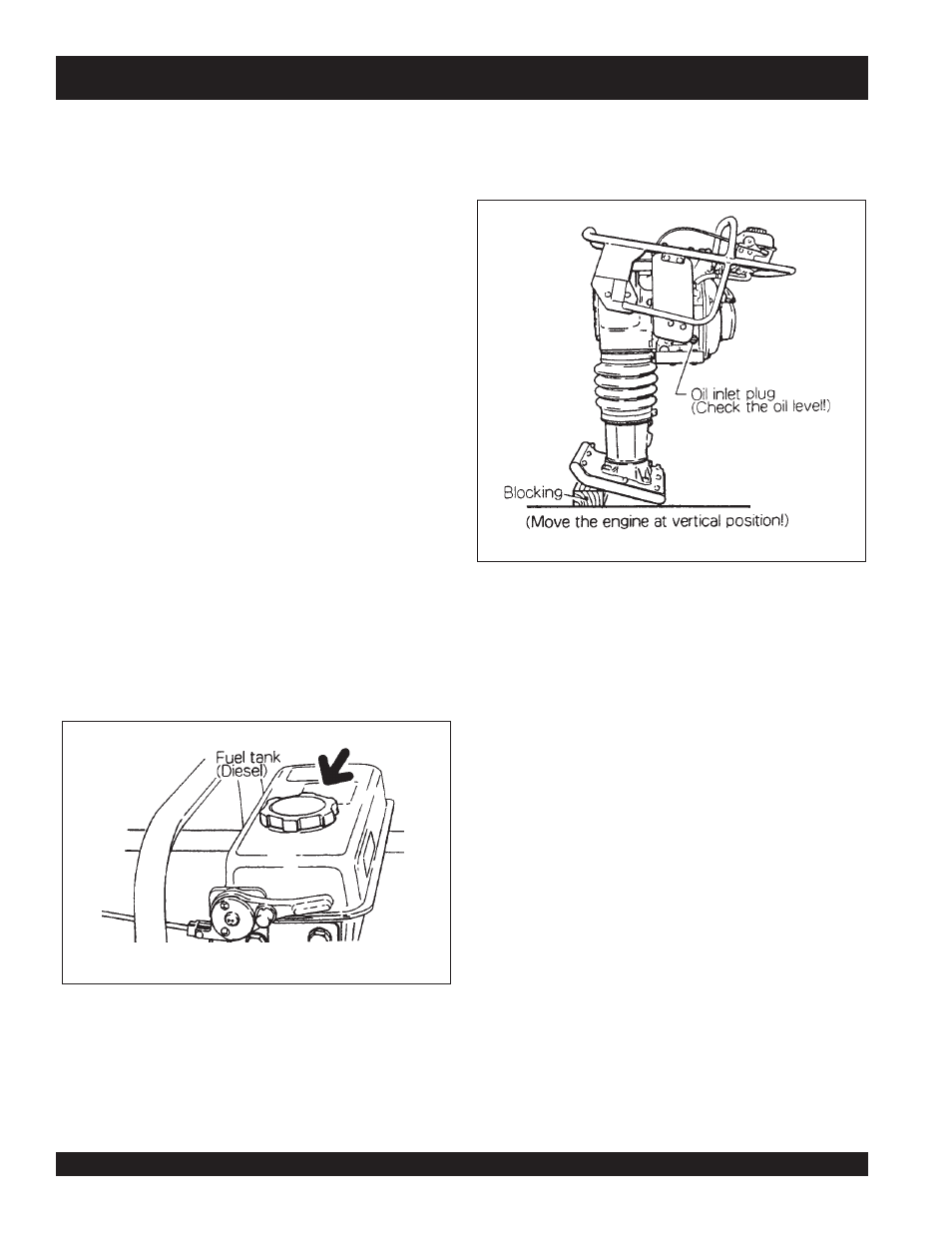

Rammer Gearbox and Spring Cylinder. This unit uses an oil

bath lubrication system. Check oil level through oil level sight

glass at rear of tamper foot. If oil is not visible, add #10W-30

motor oil. Oil bath contains approx. 1.7 pt. (800cc) for MT-86D.

3-3. Engine:

Use only automobile diesel fuel (Fig. 1). Check the engine oil

before starting operation and fill the oil regularly (Fig. 2). For

checking the oil level, move the engine to vertical position and

check that the oil is level with the oil inlet (about 700cc).

3-4. Check all nuts, bolts and fasteners for tightness. Retighten

as necessary.

3-5. Clean dirt from the recoil starter and foot. Wipe entire unit

clean before operating.

3-6. Replace any missing or damaged Safety/Operation decals.

MT-86D — OPERATION

Fig. 1

Fig. 2