Motorola LS1013 User Manual

Page 14

14

4.

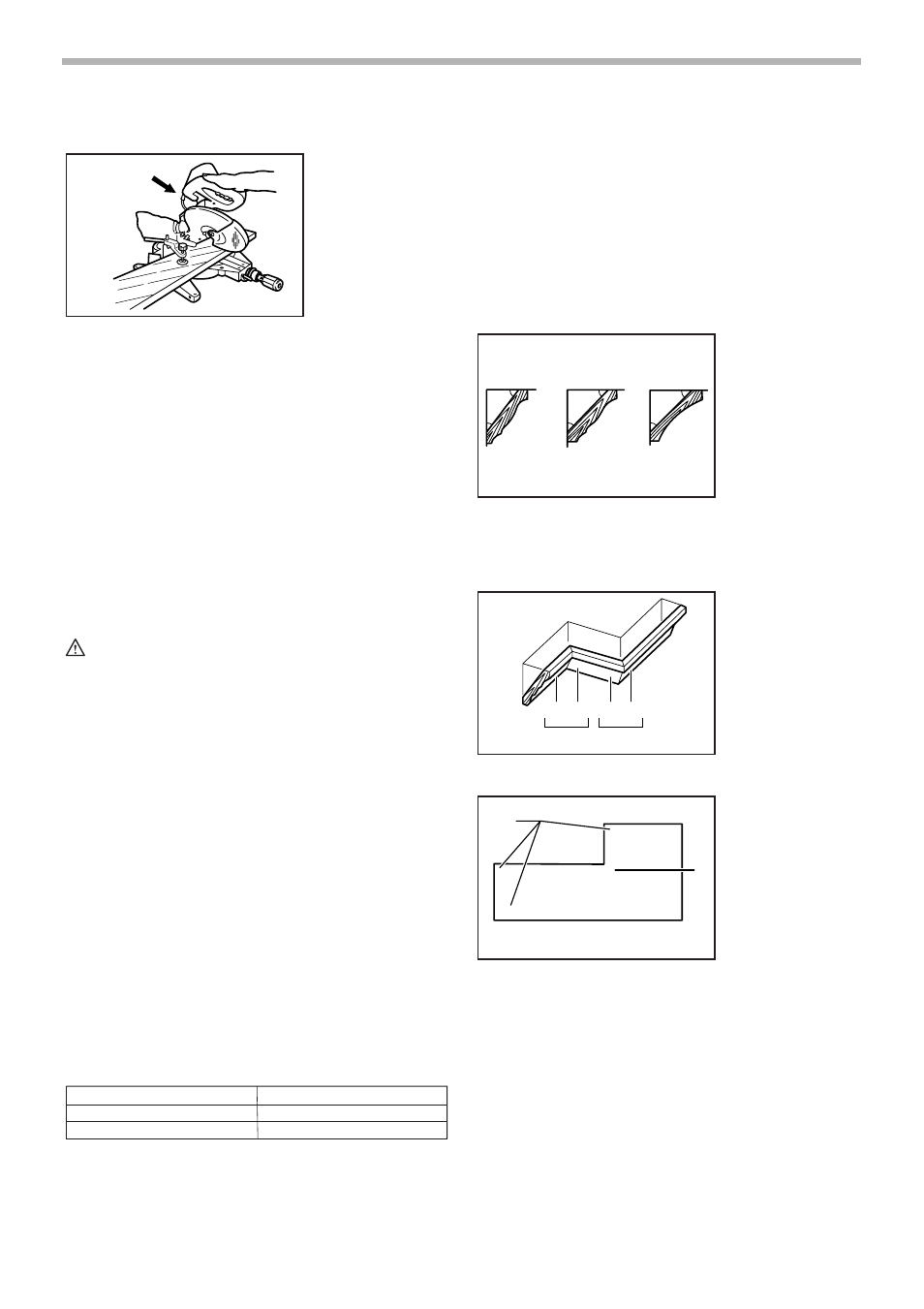

Bevel cut

Loosen the lever and tilt the saw blade to set the

bevel angle (Refer to the previously covered

“Adjusting the bevel angle”). Be sure to retighten

the lever firmly to secure the selected bevel angle

safely. Secure the workpiece with a vise. Make sure

the carriage is pulled all the way back toward the

operator. Switch on the tool without the blade mak-

ing any contact and wait until the blade attains full

speed. Then gently lower the handle to the fully

lowered position while applying pressure in parallel

with the blade and PUSH THE CARRIAGE

TOWARD THE GUIDE FENCE TO CUT THE

WORKPIECE. When the cut is completed, switch

off the tool and WAIT UNTIL THE BLADE HAS

COME TO A COMPLETE STOP before returning

the blade to its fully elevated position.

CAUTION:

•

Always be sure that the blade will move down to

bevel direction during a bevel cut. Keep hands out

of path of saw blade.

•

During a bevel cut, it may create a condition

whereby the piece cut off will come to rest against

the side of the blade. If the blade is raised while the

blade is still rotating, this piece may be caught by

the blade, causing fragments to be scattered which

is dangerous. The blade should be raised ONLY

after the blade has come to a complete stop.

•

When pressing down the handle, apply pressure in

parallel with the blade. If a force is applied

perpendicularly to the turn base or if the pressure

direction is changed during a cut, the precision of

the cut will be impaired.

•

Always set the sub-fence to the left position when

performing left bevel cuts.

5.

Compound cutting

Compound cutting is the process in which a bevel

angle is made at the same time in which a miter

angle is being cut on a workpiece. Compound cut-

ting can be performed at angle shown in the table.

When performing compound cutting, refer to “Press

cutting”, “Slide cutting”, “Miter cutting” and “Bevel

cut” explanations.

6.

Cutting crown and cove moldings

Crown and cove moldings can be cut on a com-

pound miter saw with the moldings laid flat on the

turn base.

There are two common types of crown moldings

and one type of cove moldings; 52/38° wall angle

crown molding, 45° wall angle crown molding and

45° wall angle cove molding. See illustrations.

There are crown and cove molding joints which are

made to fit “Inside” 90° corners ((1) and (2) in Fig.

A) and “Outside” 90° corners ((3) and (4) in Fig. A).

Measuring

Measure the wall length and adjust workpiece on

table to cut wall contact edge to desired length.

Always make sure that cut workpiece length at the

back of the workpiece is the same as wall length.

Adjust cut length for angle of cut. Always use sev-

eral pieces for test cuts to check the saw angles.

When cutting crown and cove moldings, set the

bevel angle and miter angle as indicated in the

table (A) and position the moldings on the top sur-

face of the saw base as indicated in the table (B).

001554

Miter angle

Bevel angle

Left 0˚ - 47˚, Right 0˚ - 45˚

Left and Right 0˚ - 45˚

Right 52˚

Left 0˚ - 40˚and Right 0˚ - 45˚

006360

1. 52/38° type

crown molding

2. 45° type crown

molding

3. 45° type cove

molding

1. Inside corner

2. Outside corner

1. Inside corner

2. Outside corner

52

∞

38

∞

45

∞

45

∞

45

∞

45

∞

1

2

3

001555

(1) (2) (3) (4)

1

2

Fig.A

001556

2

(1)

(2)

(1)

(2)

(2)

(1)

(2)

(1)

(1)

(2)

(3)

(4)

1

001557