Conditions that affect weld bead shape, 4. conditions that affect weld bead shape – Miller Electric XLT 185 User Manual

Page 37

OM-230 832 Page 33

9-4.

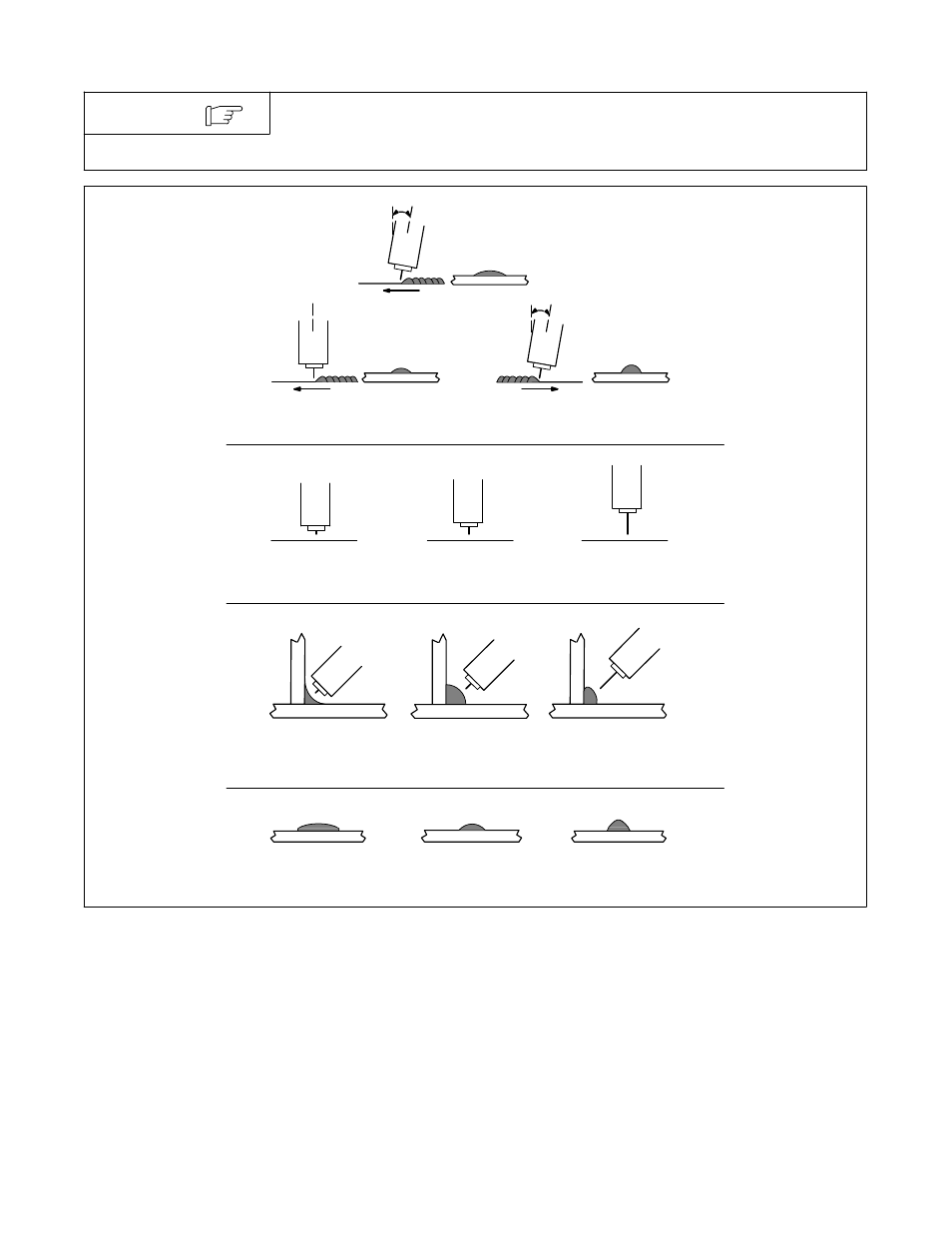

Conditions That Affect Weld Bead Shape

Weld bead shape depends on gun angle, direction of travel, electrode extension

(stickout), travel speed, thickness of base metal, wire feed speed (weld current),

and voltage.

NOTE

Slow

FILLET WELD ELECTODE EXTENSIONS (STICKOUT)

ELECTRODE EXTENSIONS (STICKOUT)

GUN ANGLES AND WELD BEAD PROFILES

10

°

10

°

GUN TRAVEL SPEED

S-0634

Push

Perpendicular

Drag

Short

Normal

Long

Short

Normal

Long

Normal

Fast

.

Use a Drag Technique

with self-shielding flux

cored wire.

See also other documents in the category Miller Electric Tools:

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- S-32S (4 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)