Lmvh-r60h — maintenance, Caution - general maintenance safety maintenance, Always – Multiquip Mikasa Reversable Plate Compator MVH-R60H User Manual

Page 20

PAGE 20 — MVH-R60H— OPERATION AND PARTS MANUAL — REV. #1 (09/09/04)

l

MVH-R60H — MAINTENANCE

N

O

I

T

C

E

P

S

N

I

E

N

I

G

N

E

.

7

E

L

B

A

T

)l

a

u

n

a

M

e

n

i

g

n

E

e

t

a

r

a

p

e

s

e

e

s

,

s

li

a

t

e

d

r

o

F

(

m

e

t

I

n

o

i

t

a

r

e

p

O

f

o

s

r

u

o

H

l

e

u

f

r

o

li

o

f

o

e

g

a

k

a

e

L

s

r

u

o

h

8

y

r

e

v

E

)

y

li

a

D

k

c

e

h

C

(

s

d

a

e

r

h

t

g

n

i

n

e

t

s

a

f

f

o

s

s

e

n

t

h

g

i

T

)

y

li

a

D

k

c

e

h

C

(

s

r

u

o

h

8

y

r

e

v

E

k

c

e

h

c

li

o

e

n

i

g

n

E

t

n

e

m

h

s

i

n

e

l

p

e

r

d

n

a

)

y

li

a

D

k

c

e

h

C

(

s

r

u

o

h

8

y

r

e

v

E

)l

e

v

e

l

.

x

a

m

d

e

if

i

c

e

p

s

o

t

h

s

i

n

e

l

p

e

R

(

t

n

e

m

h

s

i

n

e

l

p

e

r

li

o

e

n

i

g

n

E

s

r

u

o

h

0

0

1

y

r

e

v

e

n

e

h

t

,

s

r

u

o

h

0

2

t

s

ri

F

g

n

i

n

a

e

l

c

r

e

n

a

e

l

c

ri

A

s

r

u

o

h

0

5

y

r

e

v

E

N

O

I

T

C

E

P

S

N

I

E

N

I

H

C

A

M

.

6

E

L

B

A

T

m

e

t

I

n

o

i

t

a

r

e

p

O

f

o

s

r

u

o

H

s

k

r

a

m

e

R

)

k

c

e

h

c

g

n

it

r

a

t

S

(

s

r

u

o

h

8

y

r

e

v

E

)

y

a

d

y

r

e

v

e

(

t

s

o

l

r

o

d

e

n

e

s

o

o

L

s

w

e

r

c

s

s

r

u

o

h

8

y

r

e

v

E

)

y

a

d

y

r

e

v

e

(

t

r

a

p

y

n

a

f

o

e

g

a

m

a

D

s

r

u

o

h

8

y

r

e

v

E

)

y

a

d

y

r

e

v

e

(

g

n

il

l

o

r

t

n

o

c

f

o

n

o

it

c

n

u

F

t

r

a

p

m

e

t

s

y

s

s

r

u

o

h

8

y

r

e

v

E

)

y

a

d

y

r

e

v

e

(

c

il

u

a

r

d

y

h

f

o

k

a

e

L

m

e

t

s

y

s

s

r

u

o

h

0

0

1

y

r

e

v

E

.

1

2

e

g

a

p

e

e

S

k

c

e

h

c

li

o

r

o

t

a

r

b

i

V

s

r

u

o

h

0

0

3

y

r

e

v

E

.

2

2

e

g

a

p

e

e

S

t

n

e

m

e

c

a

l

p

e

r

li

o

r

o

t

a

r

b

i

V

s

r

u

o

h

0

0

1

y

r

e

v

E

.

2

2

e

g

a

p

e

e

S

k

c

e

h

c

li

o

c

il

u

a

r

d

y

H

n

e

h

t

,

s

r

u

o

h

0

0

2

t

s

ri

F

.

s

r

h

0

0

0

1

y

r

e

v

e

.

3

2

e

g

a

p

e

e

S

k

c

e

h

c

)

h

c

t

u

l

c

(

tl

e

b

-

V

s

r

u

o

h

0

0

2

y

r

e

v

E

.

2

2

e

g

a

p

e

e

S

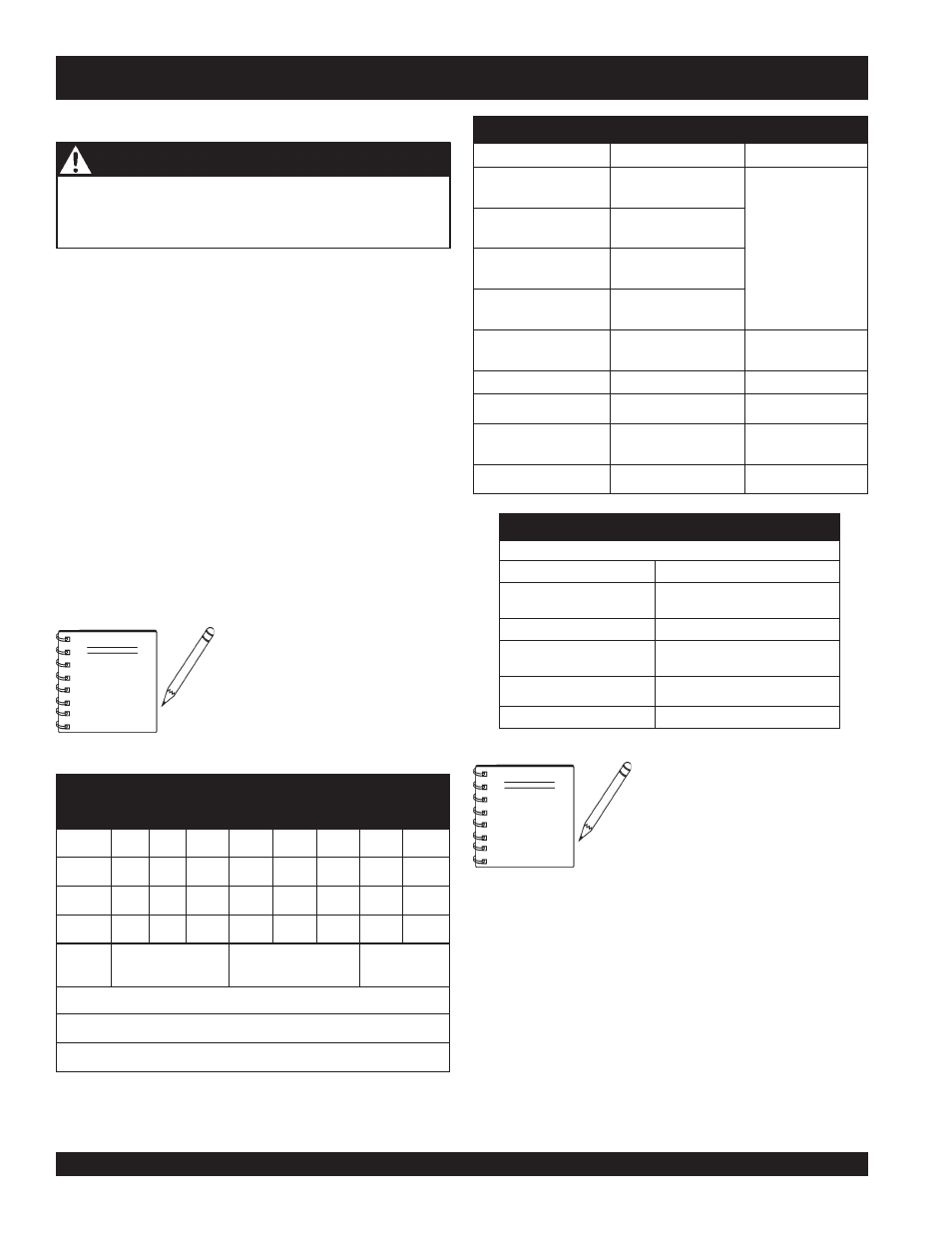

Inspection and Maintenance Service Tables.

To make sure your plate compactor is always in good working

condition before using, carry out the maintenance inspection in

accordance with Tables 5 through 7.

These inspection intervals are for

operation under normal conditions.

Adjust your inspection intervals

based on the number hours plate

compactor is in use, and particular

working conditions.

E

U

Q

R

O

T

G

N

I

N

E

T

H

G

I

T

.

5

E

L

B

A

T

r

e

t

e

m

a

i

D

)

m

c

/

g

k

.

n

i

(

l

a

i

r

e

t

a

M

m

m

6

m

m

8

m

m

0

1

m

m

2

1

m

m

4

1

m

m

6

1

m

m

8

1

m

m

0

2

T

4

0

7

0

5

1

0

0

3

0

0

5

0

5

7

0

0

1

,

1

0

0

4

,

1

0

0

0

,

2

T

8

-

6

0

0

1

0

5

2

0

0

5

0

0

8

0

0

3

,

1

0

0

0

,

2

0

0

7

,

2

0

0

8

,

3

T

1

1

0

5

1

0

0

4

0

0

8

0

0

2

,

1

0

0

0

,

2

0

0

9

,

2

0

0

2

,

4

0

0

6

,

5

*

0

0

1

)

m

m

6

(

0

5

3

~

0

0

3

)

m

m

8

(

0

0

7

~

0

5

6

)

m

m

0

1

(

)

m

u

n

i

m

u

l

a

f

o

s

i

t

r

a

p

-

r

e

t

n

u

o

c

e

s

a

c

n

I

(

*

.

w

e

r

c

s

d

n

a

,t

l

o

b

h

c

a

e

n

o

d

e

k

r

a

m

s

i

l

a

i

r

e

t

a

m

f

o

y

ti

l

a

u

q

d

n

a

l

a

i

r

e

t

a

M

d

e

d

n

a

h

t

h

g

i

r

ll

a

e

r

a

e

n

i

h

c

a

m

s

i

h

t

h

ti

w

e

s

u

n

i

s

d

a

e

r

h

T

:

e

t

o

N

Fuel piping and connections should

be replaced every 2 years.

Daily Service

z

Check for leakage of fuel or oil.

z Check for loose screws including tightness. See Table 7

below (tightening torque ), for retightening:

z Remove soil and clean the bottom of compaction plate.

z Check hydraulic pump, piping and hose for any leakage. A

loosened hydraulic hose can be a cause for leakage. Check

hydraulic hose connections with wrench applied for

tightness.

z Check engine oil, see Inspection section.

CAUTION - General Maintenance Safety

Maintenance

Inspection and other services should

always

be carried out

on hard and level ground with the engine shutdown.

NOTE

NOTE