Milwaukee 4270-20 User Manual

Page 8

page 8

OPERATION

WARNING!

To reduce the risk of injury, wear safety goggles or glasses

with side shields.

Typical Operation

1. Check the work surface to make sure it is clean and free of foreign

materials.

Paint, rust, scale or uneven surfaces decrease the holding strength

of the magnet. Chips, burrs, dirt and other foreign materials on the

surface of the magnetic base will also decrease holding power. Use

a smooth, flat file to keep the magnet clean and free of nicks.

The electromagnetic drill press attaches magnetically to 3/8" or thicker

ferrous stock. Do not use on stock less than 3/8". The magnetic

base WILL NOT hold on nonmagnetic grades of stainless steel.

2. To install/remove cutter:

4. Move the spindle up so the cutter and center pin are above the work

surface.

Do not use cutting fluid in an overhead or any other posi-

tion that allows cutting fluid to enter motor or switch

enclosure.

Wet connections are shock hazards. Prevent cutting fluid

from traveling along cord and contacting the outlet, ex-

tension cord connections or tool plug. Each time tool is

plugged in, elevate extension cord or gang box connec-

tions and arrange a drip loop (See Fig. 6). If plug or con-

nections get wet, turn power off to outlet before

unplugging tool.

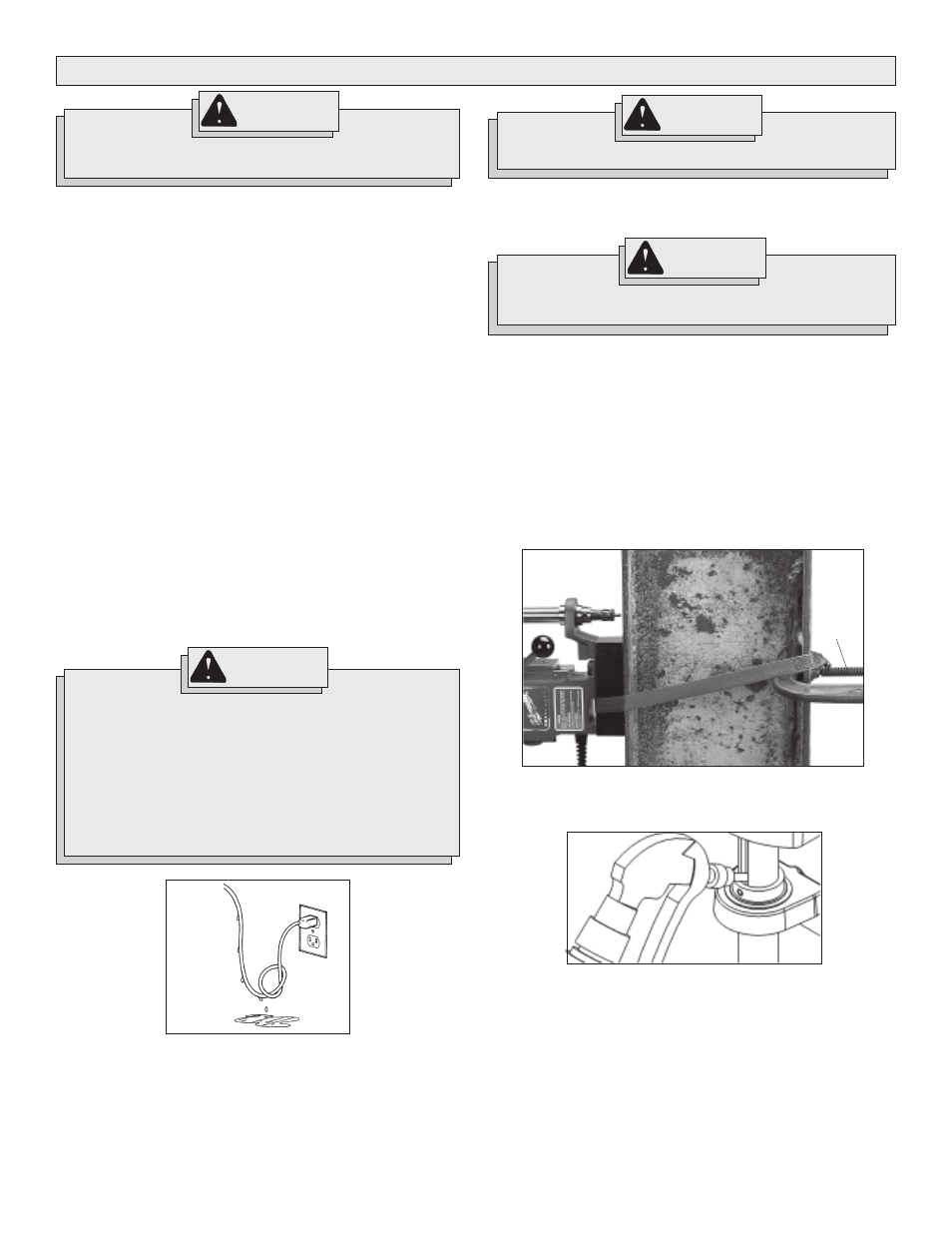

Fig. 6

WARNING!

A.

Raise the drill motor to its highest position. Tighten stop knob.

B.

Insert cutter into drill spindle with the two (2) flats of the cutter

aligned with set screws. Make sure the center pin is inserted

into the cutter.

NOTE: Cutter should be fully seated into drill spindle.

C.

Tighten set screws with 3/16" hex key provided.

D.

Loosen the stop knob.

E.

Reverse procedure to remove cutter.

NOTE: Do not remove cutter unless slug is removed. Slug may

eject unexpectedly.

Avoid contact with cutter tips. Periodically inspect the cutter tips for

loose or damaged tips.

3. Plug in tool to power source.

5. Position the tool so the center pin is directly over the desired cutting

location. Push the magnet switch to the ON position. The magnet

indicator light will turn on.

The cutting fluid reservoir will empty as the center pin contacts the

work surface. When notching or slotting, it is required to spray

cutting fluid directly to the cutter and work piece with the supplied

hand pump. Keep hand pump away from moving parts. Failure to

use the lubricant properly will cause cutter damage.

The use of HAWG WASH® cutting fluid is recommended for long life

of these cutters. The operator is responsible for the application of

lubricants other than HAWG WASH® cutting fluid.

In overhead or vertical cutting applications, do not use cutting

fluids. Use only lubricant pastes or sprays recommended for high speed

cutting. Do not allow lubricant pastes and sprays to enter tool.

Fig. 8

7. With the drill on/off switch in the "OFF" position, fill the cutting fluid

reservoir with cutting fluid through the slots in the drill spindle

(Fig. 8).

Fig. 7

C-clamp

To reduce the risk of injury, do not hold workpiece by hand.

WARNING!

6. Use a safety strap on vertical or overhead situations (Fig. 7).

A.

Route the safety strap, ring side first, through the lower slot,

and wrap it tightly around a solid, rigid structure as shown.

Make sure the strap is not twisted.

B.

Hook the safety strap snaphook provided to the ring.

Eliminate any slack in the strap.

C.

When using on a vertical surface, secure the safety strap

with a c-clamp or similar device. This will hold the strap in

place and prevent the tool from sliding down the vertical

surface.

NOTE: Do not clamp to the strap. This may damage the strap

and cause it to break (Fig. 7).

To reduce the risk of injury, always use a safety strap when

drilling overhead or on a vertical surface.

WARNING!