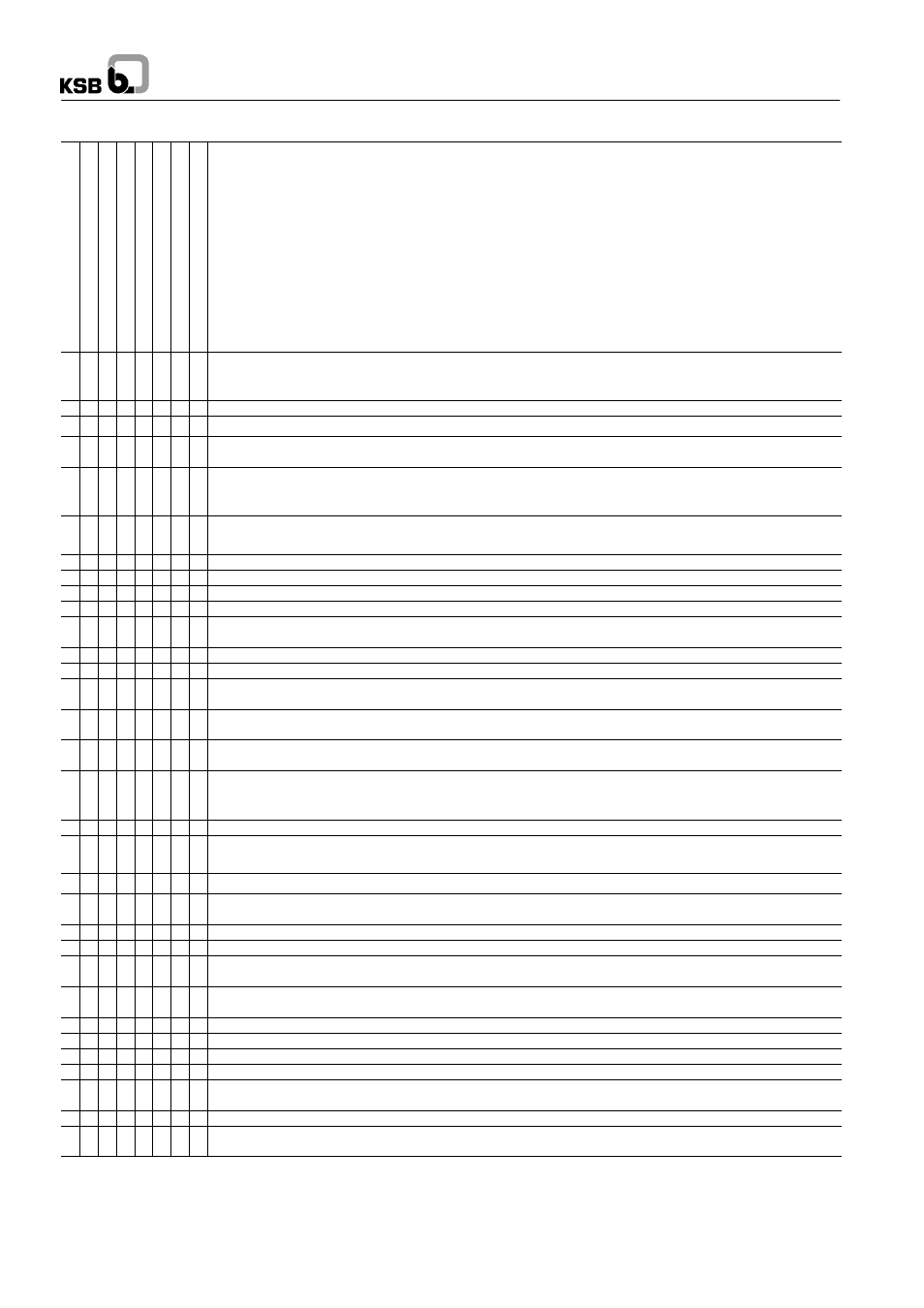

Multitec, 8trouble-shooting – Multitech 1777.8/7-10 G3 User Manual

Page 26

P

ump

del

iv

er

s

ins

uffi

ci

ent

flow

rate

Motor

is

ov

er

loaded

P

ump

is

runni

ng,

but

does

not

del

iv

er

E

xc

es

si

ve

bear

ing

temper

atur

e

Leak

age

at

the

pump

E

xce

ssive

le

aka

ge

at

th

e

sh

af

tse

al

V

ibr

ati

ons

dur

ing

pump

oper

ati

on

E

xce

ssive

rise

of

te

m

pe

ra

tu

re

in

sid

e

th

e

pu

m

p

Multitec

26

8

Trouble-shooting

Cause

Remedy

1)

*

*

*

Pump delivers against an excessively high discharge pressure.

Re-adjust to duty point.

Check plant for impurities.

Fit one or several larger impellers.

Increase the speed (turbine, I.C. engine).

*

*

* *

Pump or piping are not completely vented or primed.

Vent and/or prime.

*

*

Supply line or impeller clogged.

Remove deposits in the pump and/or piping.

*

*

Formation of air pockets in the piping.

Alter piping layout.

Fit a vent valve.

*

*

* * *

Suction head is too high / NPSH

available

(positive suction head) is too low.

Check/alter liquid level.

Fully open shut-off valve in the suction line.

Change suction line, if the friction losses in the suction line are too high.

Check suction strainer/foot valve and suction line for clogging.

*

*

Air intake at the shaft seal.

Clean barrier liquid duct, supply external barrier liquid, if necessary

2) 3)

, or

increase its pressure.

Fit new shaft seal.

*

*

*

Wrong direction of rotation.

Interchange two of the phases of the power supply cable.

*

Speed is too low.

2)

Increase speed.

* *

*

*

Wear of internal pump parts.

Replace worn components by new ones.

*

*

Pump back pressure is lower than specified in the purchase order.

Adjust duty point accurately.

* *

Density or viscosity of the fluid pumped is higher than stated in the pur-

chase order.

2)

*

*

*

Gland cover too tight or askew.

Correct. Increase leakage slightly.

*

Speed is too high.

Reduce speed.

2)

*

Tie bolts / gaskets

Tighten the bolts.

Fit new gaskets.

*

Worn shaft seal.

Fit new shaft seal.

Check barrier liquid pressure

2) 3)

*

Score marks or roughness on shaft protecting sleeve / shaft sleeve.

Replace shaft protecting sleeve / shaft sleeve.

Fit new shaft seal.

*

Vibrations during pump operation

Improve suction conditions.

Re-align the pump.

Re-balance the impeller.

Increase pressure at the pump suction nozzle.

*

* *

The unit is misaligned.

Re-align.

*

* *

Pump is warped or sympathetic vibrations in the piping.

Check pipeline connections and secure fixing of pump; if required, reduce

the distances between the pipe clamps.

Fix the pipelines using anti-vibration material.

*

Outer bearing races of fixed bearing are loose.

Clamp outer bearing races axially.

*

Increased axial thrust.

2)

Check rotor clearances, axial adjustment and clearance on throttling bush

/ balance drum.

*

*

Insufficient or excessive quantity of lubricant or unsuitable lubricant.

Top up, reduce or change lubricant.

*

Non-compliance with specified coupling distance.

Correct distance according to the general arrangement drawing.

* *

Motor is running on two phases only.

Replace the defective fuse.

Check the electric cable connections.

*

* *

Rotor is out of balance.

Clean the impellers.

Re-balance the impeller.

*

* *

Defective bearing(s).

Fit new bearing(s).

*

* *

Insufficient rate of flow.

Increase the minimum rate of flow.

*

Incorrect inflow of circulation liquid.

Increase the free cross-section.

* * *

*

In case of parallel operation, check valve defective or missing.

Check.

*

Incorrect installation of gland packing,

unsuitable packing material

Check.

*

*

*

Inadequate cooling of shaft seal chamber

Check the free cross-section of the cooling liquid feed line.

*

*

*

Change in the free cross-section of the return line of the balancing liquid

Wear in balancing device

Check the balancing line.

Check throttling bush / balance drum clearances.

1) Pump pressure must be released before attempting to remedy faults on parts which are subjected to pressure.

2) Contact KSB

3) Pump version with barrier liquid supply on request only