Sensing bulb panel mount models, Using a thermowell start-up lockout – Murphy Temperature SWICHGAGE SPL User Manual

Page 2

SPL/45-94117B page 2 of 4

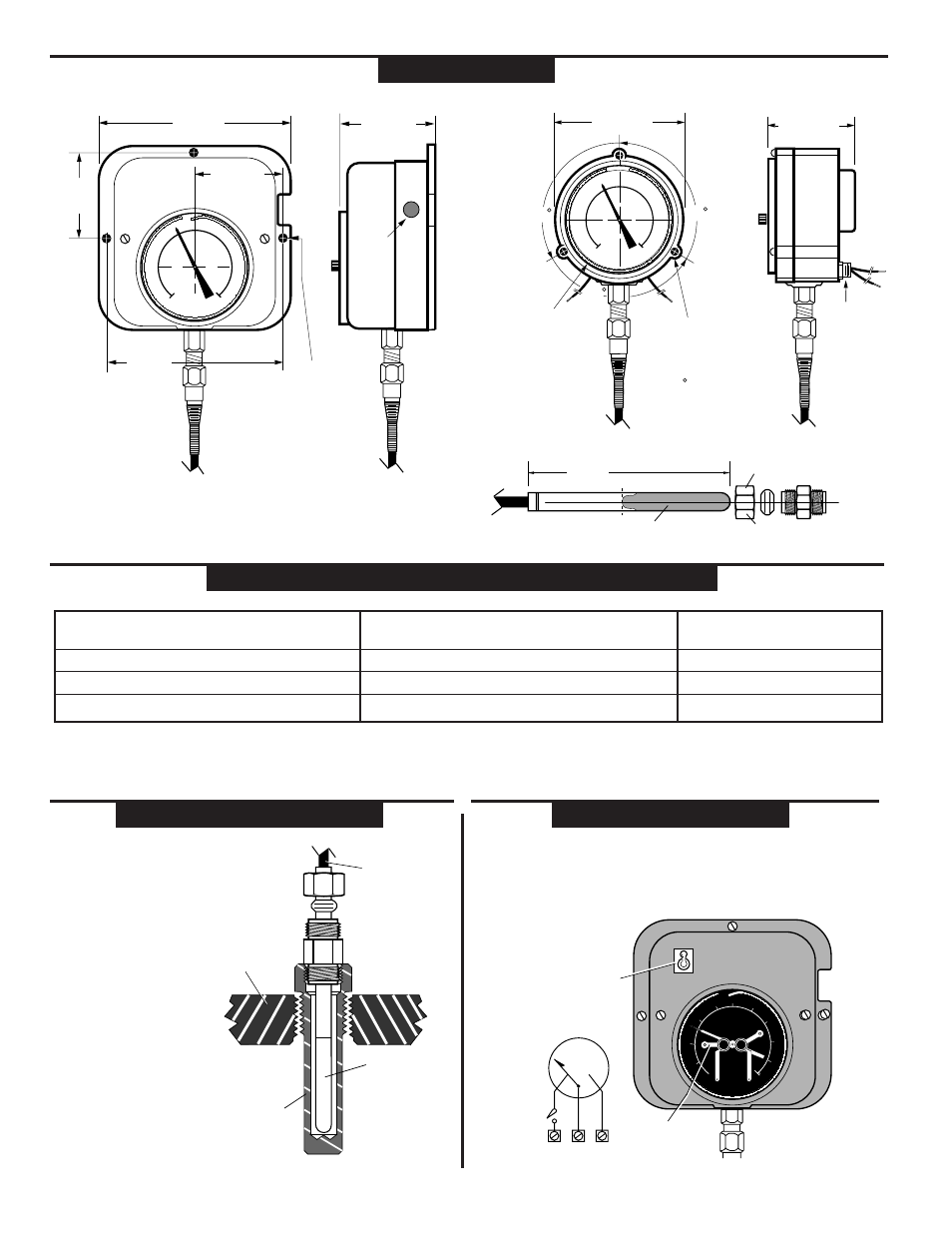

8-7/16 in.

(214 mm)

3-3/8 in.

(86 mm)

7-7/8 in.

(200 mm)

3-15/16 in.

(100 mm)

4-1/32 in.

(102 mm)

9/32 in.

(7 mm) dia.

3 places

*

SPLCE, SPLBPE, 45TEE and 45TEBPE versions feature square case,

but altered to fit standard round panel mounting–not pictured.

1/2 in.

(13 mm)

conduit

120

120

120

5-7/16 in.

(138 mm)

2-57/64 in.

(73 mm)

1/4 in. (6 mm) dia.

holes (3 places.) on

5-13/64 in. (132 mm)

b.c. (bolt circle),

120 apart, clocking

as shown

Mounting Hole

4-3/4 in.

(121 mm)

diameter.

Optional

1/2 NPT

conduit

connector

(std. with

-OS option).

7 in.

(178 mm)

1/2 NPT

Compression Nut

Bulb Minimum Insertion

Ranges and Accuracy — Sensing Bulb Insertion

Dimensions

Surface Mount Models

*

Sensing Bulb

Panel Mount Models

Temperature Ranges Available (dual scale dials)

Fahrenheit

Celsius

Accuracy (SPL and 45 Series Models)

Lower 1/4

Middle 1/2

Upper 1/4

15° to 250°F

9° to 121°C

±8°F/±4°C

±2°F/±1°C

±2°F/±1°C

5 in. (127 mm)

130° to 350°F

60° to 180°C

±8°F/±4°C

±2°F/±1°C

±3°F/±1.5°C

2-1/2 in. (64 mm)

260° to 450°F

127° to 232°C

±8°F/±4°C

±2°F/±1°C

±3°F/±1.5°C

2-1/2 in. (64 mm)

Minimum Sensing Bulb

Insertion into Process

Using a Thermowell

Start-Up Lockout

Start Up Lockout

Toggle Switch

SPLC Series

Low Limit

Contact

TEMPERATURE

MURPHY

SWICHGAGE®

TULSA, U.S.A.

270

250

220

200

170

350

340

320

300

290

°C

°F

START

RUN

Red

Toggle

switch

White Black

SPLC

The SPLC SWICHGAGE

®

low limit contact can be bypassed for equipment

start up. A toggle switch is provided for this purpose. The toggle switch must be

manually reset when temperature rises above the low limit.

Installing a thermowell is rec-

ommended for high pressure

applications or corrosive envi-

ronments. It also allows sens-

ing bulbs to be changed or

adjusted without opening the

connection to process.

Murphy offer thermowells for

a variety of applications.

For details see Murphy

bulletin T-9003B.

Sensing Bulb

Active Section

Thermowell

into the Process

Capillary

Tube

Application