House fan – Monte Carlo Fan Company 5CY60XX User Manual

Page 3

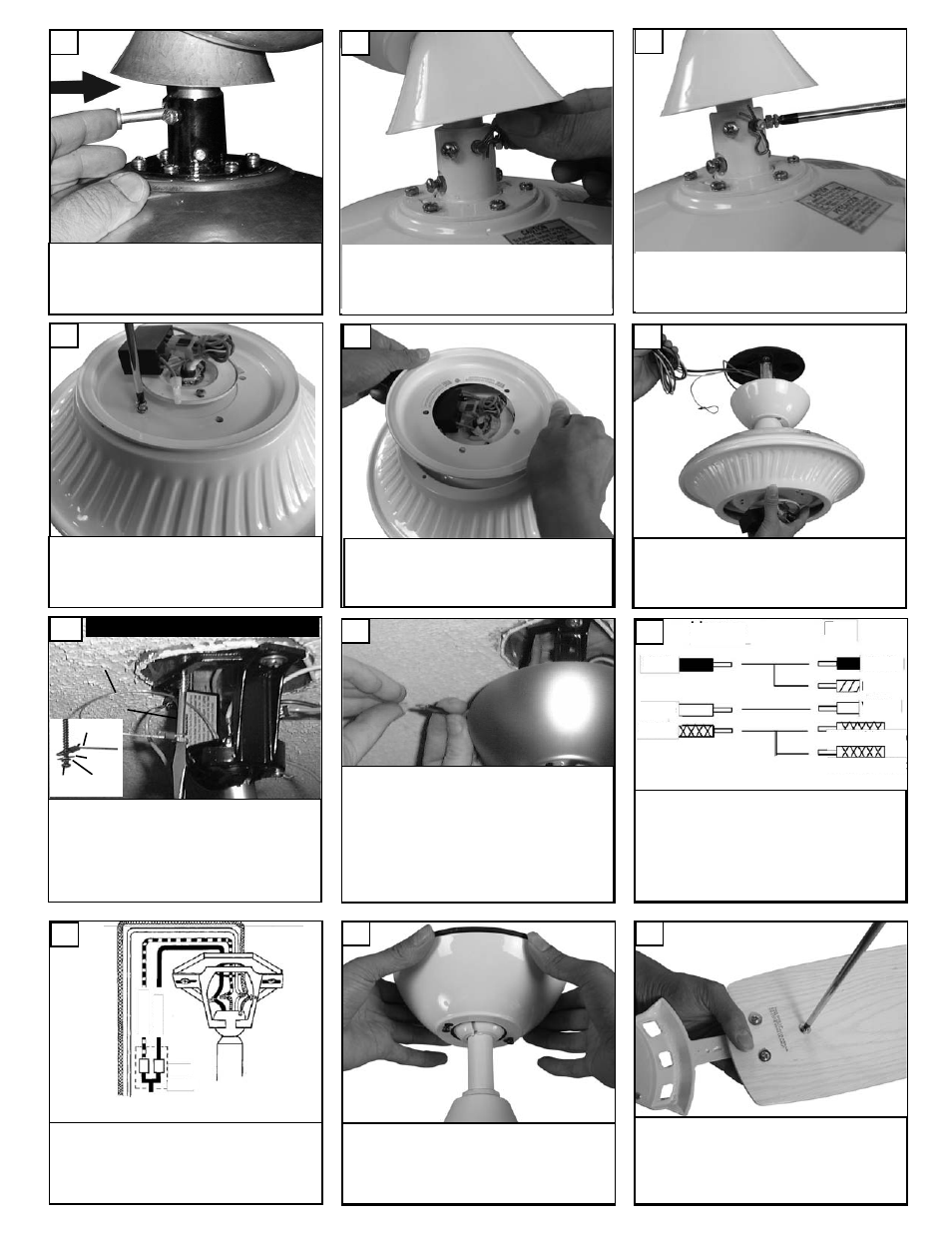

Insert downrod into motor yoke.

Next, insert clevis pin through yoke

and downrod.

Carefully lift fan assembly onto mounting

bracket. Rotate fan so that the notch on the

ball engages the ridge in the mounting bracket.

This will allow hands-free wiring.

12

7

9

Install 3 screws and washers per

blade and tighten securely. Repeat

for all 5 blades. The blades will have

a label showing this side up on each

blade.

18

Make wire connections to power source

using wire nuts provided. Make sure that

no filiments are outside of the wirenut.

After making the wire connections, the

wires should be spread apart with the

grounded conductor and the equipment-

grounding conductor on one side of the out-

let box and ungrounded conductor on the

other side of the outlet box.

14

For pullchain controls, follow diagram above.

Make sure that all exposed wiring is secured

inside wire nuts. Note: Wires from house may

vary in color and may not include ground wire.

After wiring is conplete, gently push wires into

junction box with wire nuts pointing upward.

Refer to point 3 of safety tips.

15

House

Fan

Black

White

Green

Black

White

Green(downrod)

Green(Bracket)

Blue

For control of fan and optional light from wall

location, follow diagram above. NOTE: A profes-

sional electrician is recommended for this type

of installation.

16

Raise the canopy up and align the

two holes in the canopy with the two

holes in the hanger bracket. Secure

with two screws provided.

17

Tighten both yoke set screws to fur-

ther secure downrod.

Li

gh

t

Sw

it

ch

Fa

n

Sw

it

ch

Wall

Control

8

Secure with cotter pin.

Remove screws from stabilizer plate

on bottom of fan motor.

10

11

Remove stabilizer plate you will not

need this plate.

For Canadian installation and for USA fan and

light kit combinations over 35 lbs, in both flush

and downrod mode the safety cable must be

installed into the house structure beams using

the 3” lag screws,washers, and lock washers.

provided. Make sure that when the safety cable

is fully extended the leadwires are longer than

the cable and no stress is placed on the lead-

wires.

13

Safety cable installation

Safety Cable

Lag Screw

safety

cable

3” lag

screw

lock

washer

washer