Mdr-9d — maintenance – Multiquip Mikasa Vibratory Walk-Behind Roller MDR-9D User Manual

Page 28

PAGE 28 — MQ-MIKASA MDR-9D VIBRATORY ROLLER — OPERATION AND PARTS MANUAL — REV. #0 (12/17/03)

MDR-9D — MAINTENANCE

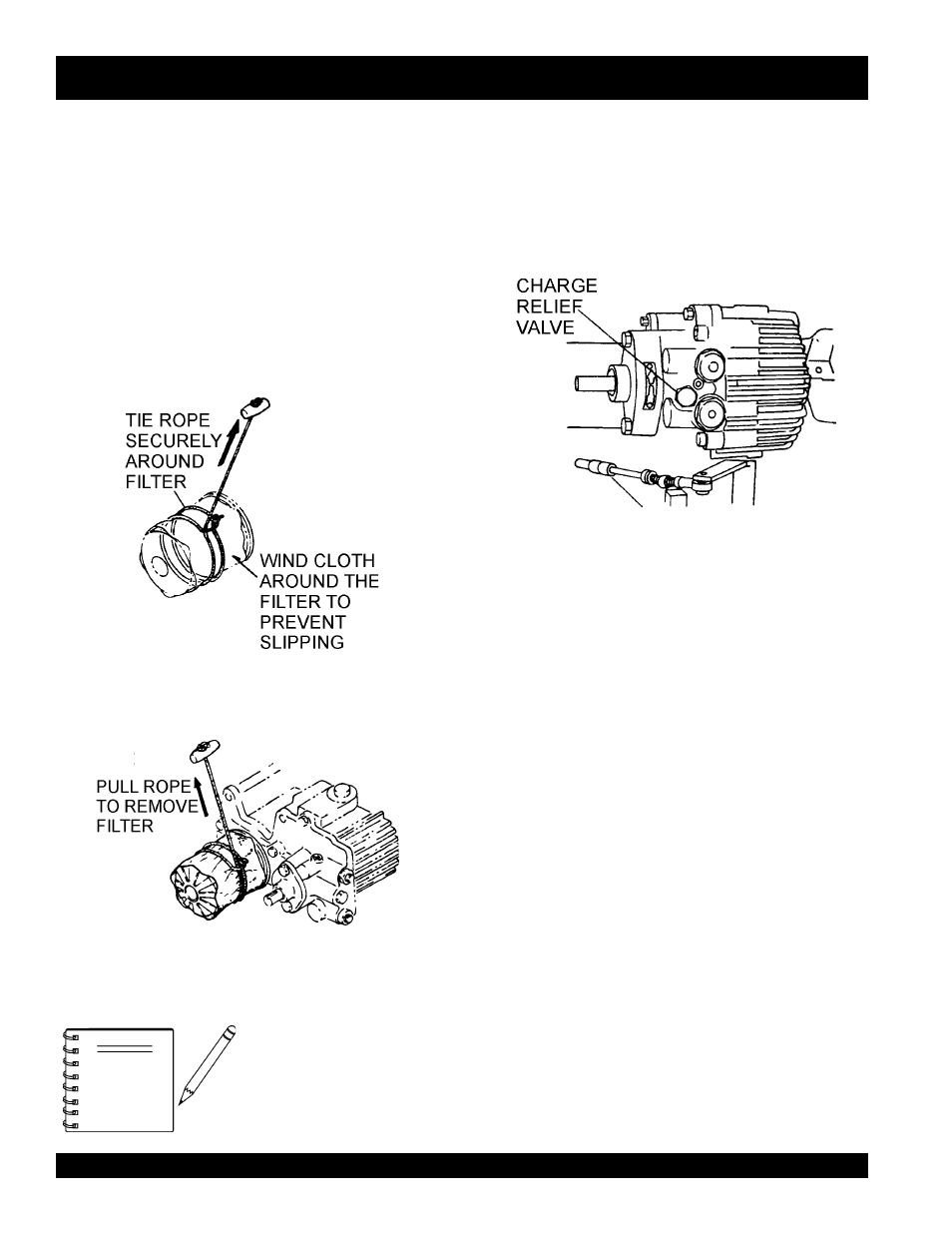

HYDRAULIC OIL FILTER CHECK

1. The hydraulic oil filter should be replaced after first 25 hours

of operation.

2. After first replacement, it should be replaced after 250 hours

operation (2 months), every 500 hours of operation (4

months), and every 1,000 hours of operation thereafter.

3. When the suction resistance exceeds 254mmHg (oil

temperature in operation is 140 degrees F), replace filter.

4. To remove the oil filter, wind a cloth around the filter to prevent

slipping (Figure 35).

5. Tie a rope securely around the filter (Figure 35).

6. Forcibly pull the rope to remove the filter (Figure 36).

7. Immediately replace with new filter, screwing it on by hand

to avoid hydraulic oil leak.

Figure 35. Cloth and Rope Around Filter

Figure 36. Filter Removal

Use only genuine Mikasa

replacement oil filters (10

micron filter paper. Do not use

automobile-type oil filters.

NOTE

HDRAULIC AIR EXTRACTION

1. After filling hydraulic oil tank with oil, loosen the oil hose

joint and check that oil is enough to reach the oil suction

and outlet ports in the hydraulic transmission. Tighten the

hose joint securely after checking.

2. Loosen the charge relief valve located on the front side of

the hydraulic transmission (Figure 37).

3. Check that oil flows out from the valve hole.

4. Replace the charge relief valve tightly.

5. With the travel and vibrator levers in neutral position, start

the engine and idle at low speed for 3 to 5 minutes.

6. Check the forward and reverse rotation of the output shaft

by moving the travel lever slowly to its forward and reverse

positions.

7. Check the oil level gauge and make sure that there are no

air bubbles mixed in the oil. After checking, operate the roller

slowly at first then at full speed.

8. When oil level in the tank is low, replenish oil up to the

specified level, and screw the cap securely with a wrench.

9. If bubbles remain in the oil or foam is found, air is being

sucked through the suction side and should be checked.

Figure 37. Loosening Charge Relief Valve