11. basic sub arc (saw) welding – Miller Electric 1000 User Manual

Page 21

OM-2221 Page 17

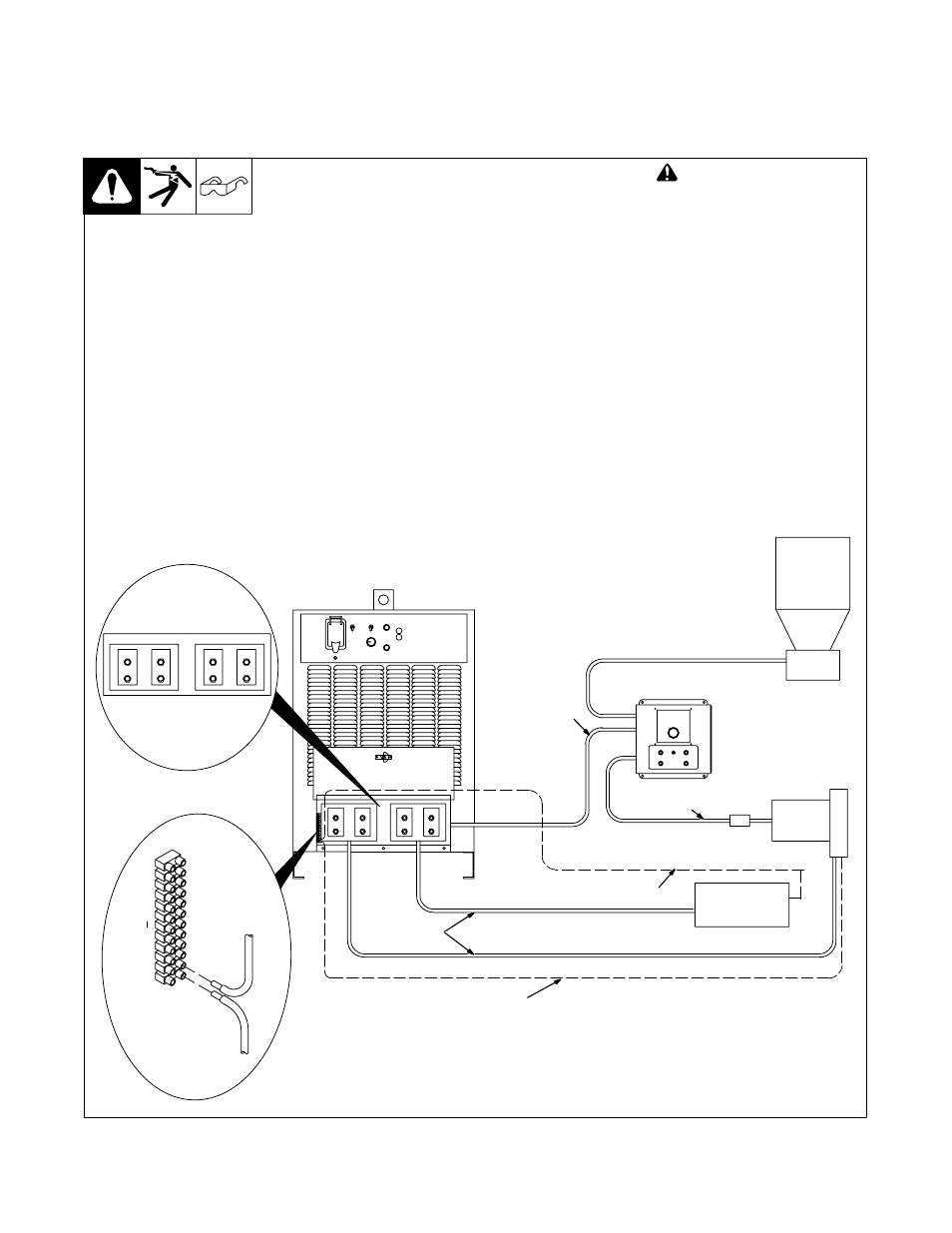

3-11. Basic Sub Arc (SAW) Welding

.

Customer must supply the following: power source, power source control cable, wire drive assembly, wire drive assembly cable, drive rolls, gun,

welding wire, weld cables, remote voltage sense leads, and flux system for the desired application.

A. Basic Sub Arc (SAW) Equipment Connections

804 738-A

!

Turn off welding power

source and weld control, and

disconnect input power be-

fore making connections.

.

Use remote voltage sense

leads in all applications.

.

Suggested size for remote volt-

age sense wire is 12 gauge or

larger.

.

For better performance for

most Sub Arc (SAW) applica-

tions, make connections to the

high inductance weld output

terminal.

.

Polarity: For DCEP (Reverse

Polarity), connect weld cables

and voltage sense leads as

shown. For DCEN (Straight

Polarity), reverse weld cables

and voltage sense leads.

Strip 1T Terminal P

1T Terminal N

From Terminal

From Terminal Strip

10-Pin Motor

Control Cord

Weld Cables

HDC Controller

14-Pin Welding

Control Cord

Power Source

Flux System

Flux

Valve

Wire

Drive

Assembly

Workpiece

A

B

C

D

E

G

J

K

L

N

P

Electrode

Work

Summit Arc 1000/1250