G32msw on the a25cw, Iso 9001 – Moffat A25CW User Manual

Page 2

In line with policy to continually develop and improve its products, Moffat Limited reserves the right to change specifications and design without notice.

Printed in New Zealand

© Copyright Moffat Ltd

Moffat/5244-G32MSW/A25CW/BH/2M/09.06

U.S.A

Moffat Inc

3765 Champion Boulevard

Winston-Salem

North Carolina 27105

Call Free 1800 551 8795

Ph 336-661 0257

Fax 336-661 9546

Email [email protected]

www.moffat.com

Canada

Serve Canada

22 Ashwarren Road

Downview

Ontario, M3J 1Z5

Ph 416-631 0601

Fax 416-631 0315

Email [email protected]

Australia

Moffat Pty Limited

740 Springvale Rd

Mulgrave

Victoria 3170

Australia

Ph 03-9518 3888

Fax 03-9518 3833

Email [email protected]

www.moffat.com.au

New Zealand

Moffat Limited

16 Osborne St

PO Box 10-001

Christchurch

New Zealand

Ph 03-389 1007

Fax 03-389 1276

Email [email protected]

www.moffat.co.nz

United Kingdom

Blue Seal Limited

Units 6-7 Mount St

Business Park

Birmingham B7 5QU

England

Ph 0121-327 5575

Fax 0121-327 9711

Email [email protected]

www.blue-seal.co.uk

www.moffat.com

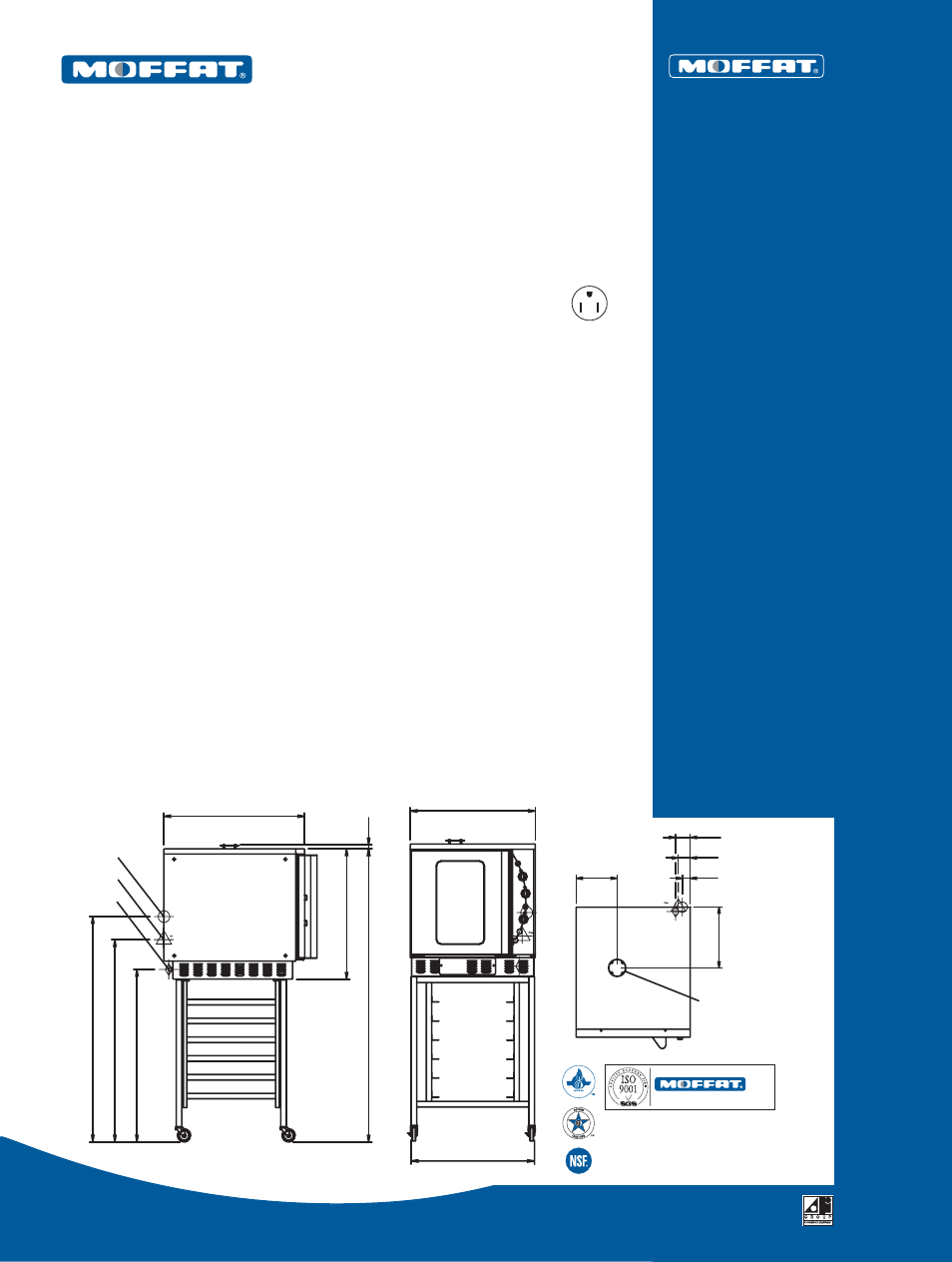

G32MSW shown on optional A25CW stand

Designed and manufactured by

QUALITY

MANAGEMENT STANDARD

ISO 9001

ISO 9001

All Turbofan products are designed and manufactured

by Moffat Ltd using the internationally recognised

ISO 9001 quality management system, covering

design, manufacture and final inspection, ensuring

consistent high quality at all times.

C O N S T R U C T I O N ( G 3 2 )

Stainless steel top and sides

Enamel oven interior

Field reversible door

Toughened twin pane door window glass

Full stainless steel door handle

4 pan capacity (4 wire oven racks included)

Fully insulated

Fully enclosed motor

C O N S T R U C T I O N ( A 2 5 )

Stainless steel frame and rack supports

Strong robust and functional

Casters

Supplied knocked down for assembly on site

C O N T R O L S

On/off switch

Mechanical thermostat,

variable between 150

°

F to 600

°

F

1 hour bake timer with buzzer

3 hour roast timer

Cook n hold factory preset at 158

°

F

(range 140

°

F to 194

°

F)

Water injection steam (momentary switch)

Low velocity fan system

2 oven lights

Infra-red burner system

C L E A N I N G A N D S E R V I C I N G

Easy clean stainless steel and enamel surfaces

Fully removable racks and baffle

Access to all controls from front panel

Full access side service panel

Removable door seals

O P T I O N S

Cookie Kit

E89 Proofer and Holding Cabinet

Double stacking kit

Full range of 18" x 26" pans

Chicken racks

S P E C I F I C AT I O N S

Gas Rating

35 MJ/hr, 33,000 Btu/hr

Gas Inlet

1

/

2

” female NPT

Electrical requirements

110-120V, 60Hz, 0.24kW, 1P+N+GND

Nema 5-15P cordset fitted

Water

3

/

4

” thread

80psi max inlet pressure

20psi min inlet pressure

External Dimensions

Width

28”

(710mm)

Height

66

1/2

” (1689mm on stand)

35

1/2

” (900mm on feet)

Depth 32”

(810mm)

Internal Dimensions (G32)

Width

18”

(460mm)

Height

20

1/2

” (520mm)

Depth

26”

(660mm)

Oven Rack Dimensions

Width

18”

(460mm)

Depth

26”

(660mm)

Between racks

5” (125mm)

3” (75mm) with cookie kit

Nett Weight (total)

287lbs

(130kg)

Packing Data (G32)

353lbs

(160kg)

23ft

3

(0.65m

3

)

Width 29

1/2

” (750mm)

Height 36

1/2

” (925mm)

Depth 37

1/4

” (945mm)

Packing Data (A25)

42lbs (19kg)

3.2ft

3

(0.09m

3

)

Width

28

3/8

” (720mm)

Height

35

1/2

” (900mm)

Depth

5

3/4

” (145mm)

Clearances

Left side 3”

(75mm)

Right side3”

(75mm)*

Rear

3”

(75mm)

Top

8”

(200mm)

GAS

1E

MWS

GAS

E

1

MWS

GAS ENTRY

ELECTRICAL ENTRY

WATER ENTRY

E

1

MWS

FLUE VENT

3

5

/

8

"

(92mm)

28"

(710mm)

32"

(810mm)

2"

(50mm)

3"

(76mm)

39"

(990mm)

45

3

/

4

"

(1162mm)

DOOR SWING

21

3

/

4

"

(550mm)

10"

(255mm)

15"

(380mm)

29

1

/

2

"

(750mm)

66

1

/

2

"

(1689mm)

51"

(1295mm)

27

1

/

2

"

(702mm)

Note: NSF certification applies to ovens only.

1"

(25mm)

G32MSW on the A25CW

Gas Convection Oven on an optional

Stainless Steel Stand

*Fixed installations require

at least 500mm(20”)

clearance at RHS for

serviceability.