Miller Electric R-115 User Manual

Page 18

OM-193 471 Page 14

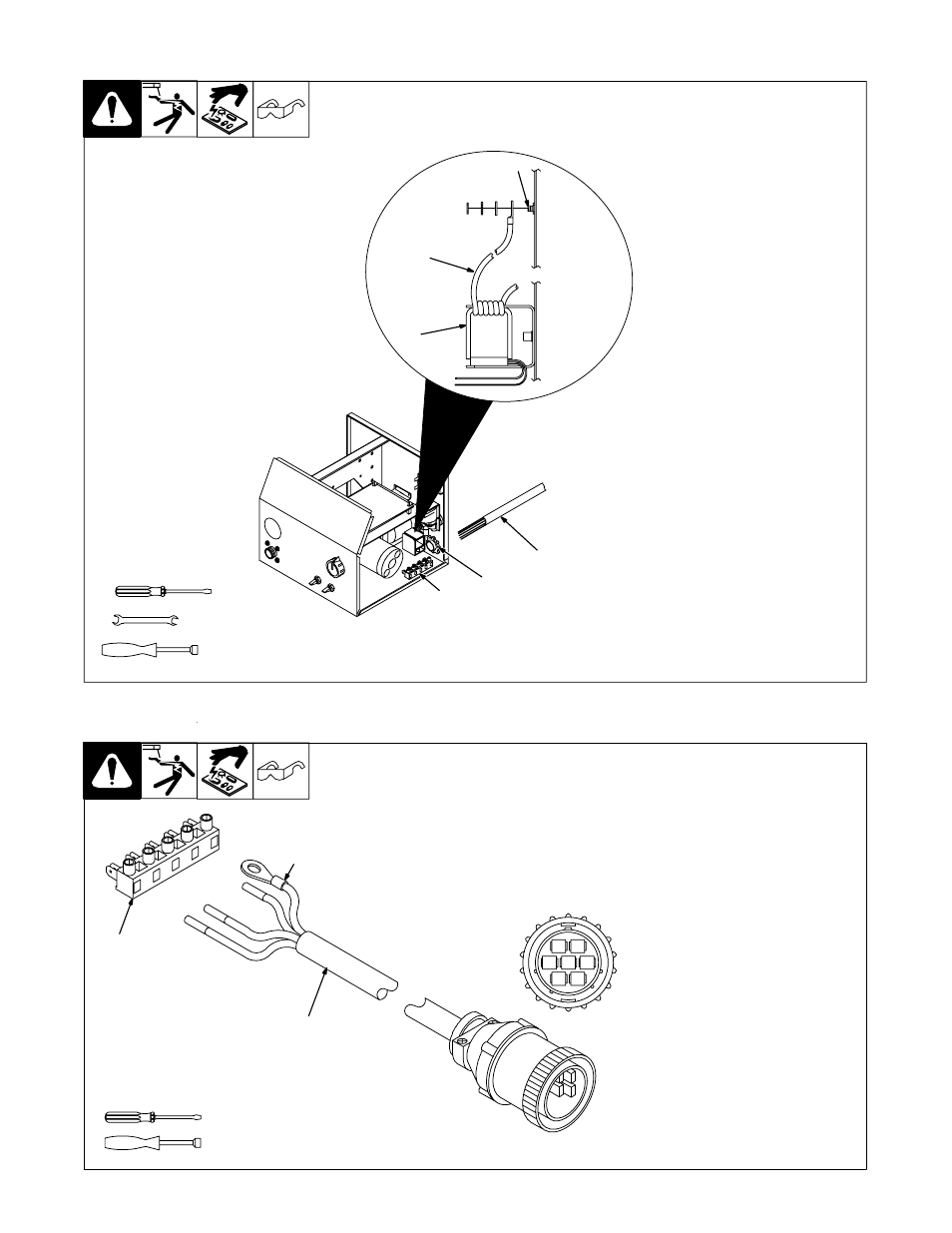

3-9. Interconnecting Power Cord Ground Lead Connection (All Models)

Ref. 802 310

.

The interconnecting power

cord is not supplied with the

unit. Be sure to obtain the prop-

er interconnecting power cord

for the welding power source

the wire feeder is being con-

nected to.

1

Strain Relief

2

Interconnecting Power Cord

.

To ensure cord will be secure in

strain relief, slide supplied tub-

ing over cord.

Insert cord through strain relief.

.

Ground lead must be wrapped

around ground current sensor

to protect ground wire against

damage from weld current.

3

Green Lead (Ground Lead)

4

Ground Current Sensor

5

Chassis Ground Stud

w/Hardware

Wrap ground lead 5 times around

ground current sensor. Connect

and secure end of ground lead to

chassis ground stud.

6

Terminal Block 1T

.

For welding power sources re-

quiring dry contact closure,

move lead 38 at terminal block

to terminal D.

Refer to Sections 3-10 through 3-17

and make additional connections to

terminal block 1T according to the

applicable procedure.

Tools Needed:

1/4 in

3/8 in

1

4

2

5

3

6

3-10. Connection For L-TEC Welding Power Sources With 7-Flat Socket Receptacle

Ref. 802 310 / Ref. 193 749

1

Terminal Block 1T

2

Interconnecting Power Cord

3

Green Lead (Connected To

Connect remaining leads to

terminal block as follows:

A: 115 VAC/Neutral Lead

B: 115 VAC/Hot Lead

C: No Connection

D: No Connection

E: 115 VAC/Contact Closure Lead

Secure strain relief clamp around

cord.

Reinstall and secure wrapper to

unit.

Connect remaining end of cord to

welding power source.

Tools Needed:

1/4 in

1

A

B

C

D

E

2

3

2

1

6

7

3

5

.

Make ground lead connections

according to Section 3-9 before

following this procedure.