Compression testing – MTD AC3 User Manual

Page 23

Troubleshooting

19

Compression testing

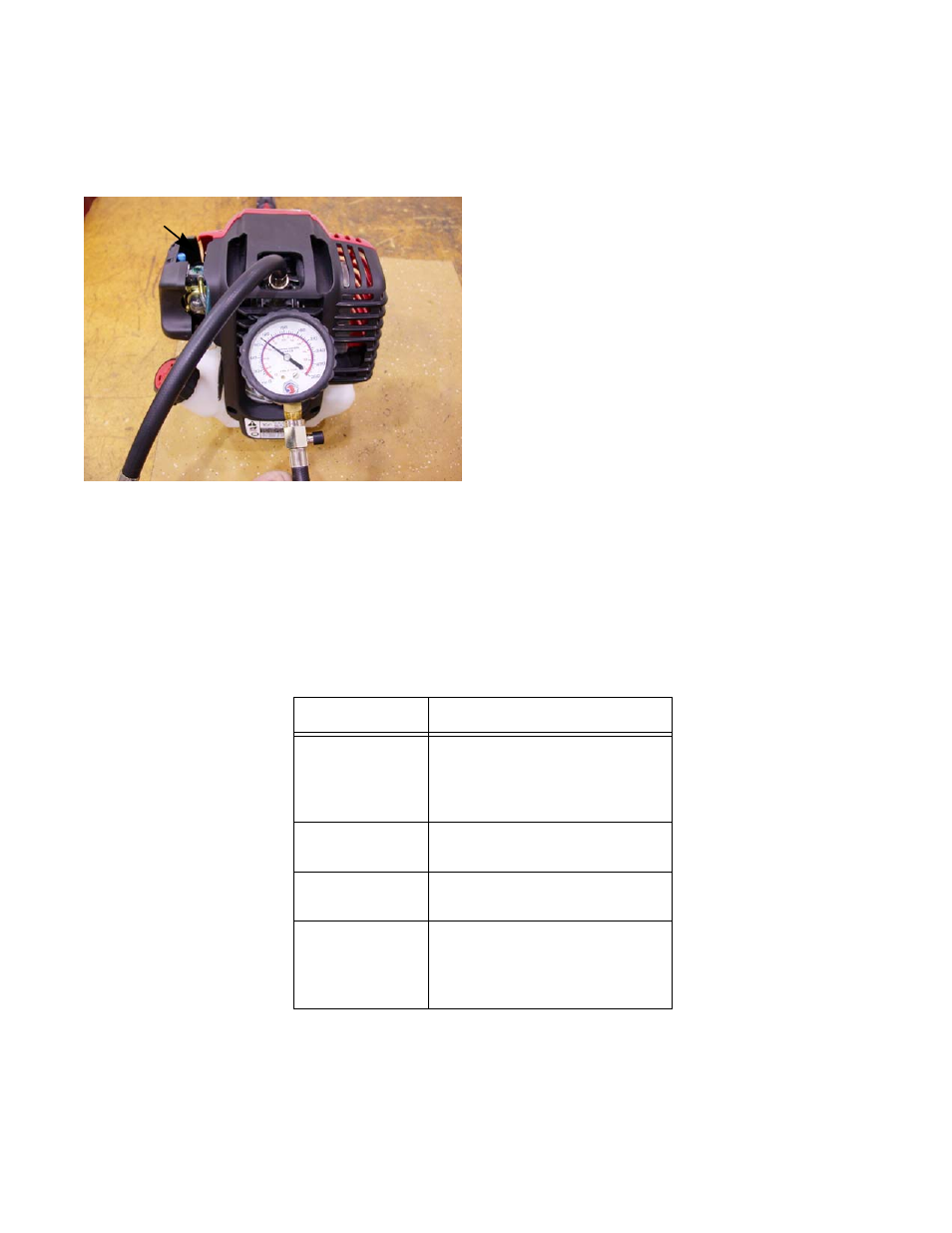

To perform a compression test:

NOTE: If the engine will run, start the engine and let it warm up first for a better reading.

1. Disconnect the high-tension lead from the spark plug

and ground it well away from the spark plug hole.

2.

Remove the spark plug using a 5/8” spark plug

socket.

3.

Pull the starter rope several times to purge any fuel

or oil from the combustion chamber.

NOTE: Air compresses readily, liquid does not. Liquid in

the combustion chamber will result in an artificially

high compression reading.

4.

Install a compression gauge in the spark plug hole.

5.

Confirm that the gauge is “zeroed”, then pull the

starter rope repeatedly, until the needle on the gauge

stops rising. See Figure 3.1.

6.

Read the gauge.

NOTE: Most good quality compression gauge sets come with a 10mm adapter is needed to thread into the

spark plug hole. If an adapter is needed, a Matco service part # CT606 or a Mityvac 05505 Compres-

sion Tester Spark Plug Adapter can be used with most gauges.

NOTE: When checking compression on small displacement engines, use a compression gauge set with the

shortest available (or no) hose.

Interpreting compression readings:

Readings in psi

Possible causes

<20

(1.4 Bar)

Most likely a stuck valve or too

tight of a valve lash, provided the

starter rope pulls with normal

effort.

20-90

(1.4 - 3 Bar)

Valve seat damage or piston ring

and/or cylinder wear.

90 - 125

(6.2 - 8.6 Bar)

Normal readings

>125

(>8.6 Bar)

Excessive valve lash, a partial

hydraulic lock, a bad cam or a

bad automatic compression

relief.

Figure 3.1

Gauge is zeroed