Assembly, Operation, Selecting correct socket – Makita 6904VH User Manual

Page 7: Installing or removing socket

7

ASSEMBLY

CAUTION:

•

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Selecting correct socket

Always use the correct size socket for bolts and nuts. An

incorrect size socket will result in inaccurate and inconsistent

fastening torque and/or damage to the bolt or nut.

Installing or removing socket

To install the socket, push it onto the anvil of the tool until it

locks into place.

To remove the socket, simply pull it off.

OPERATION

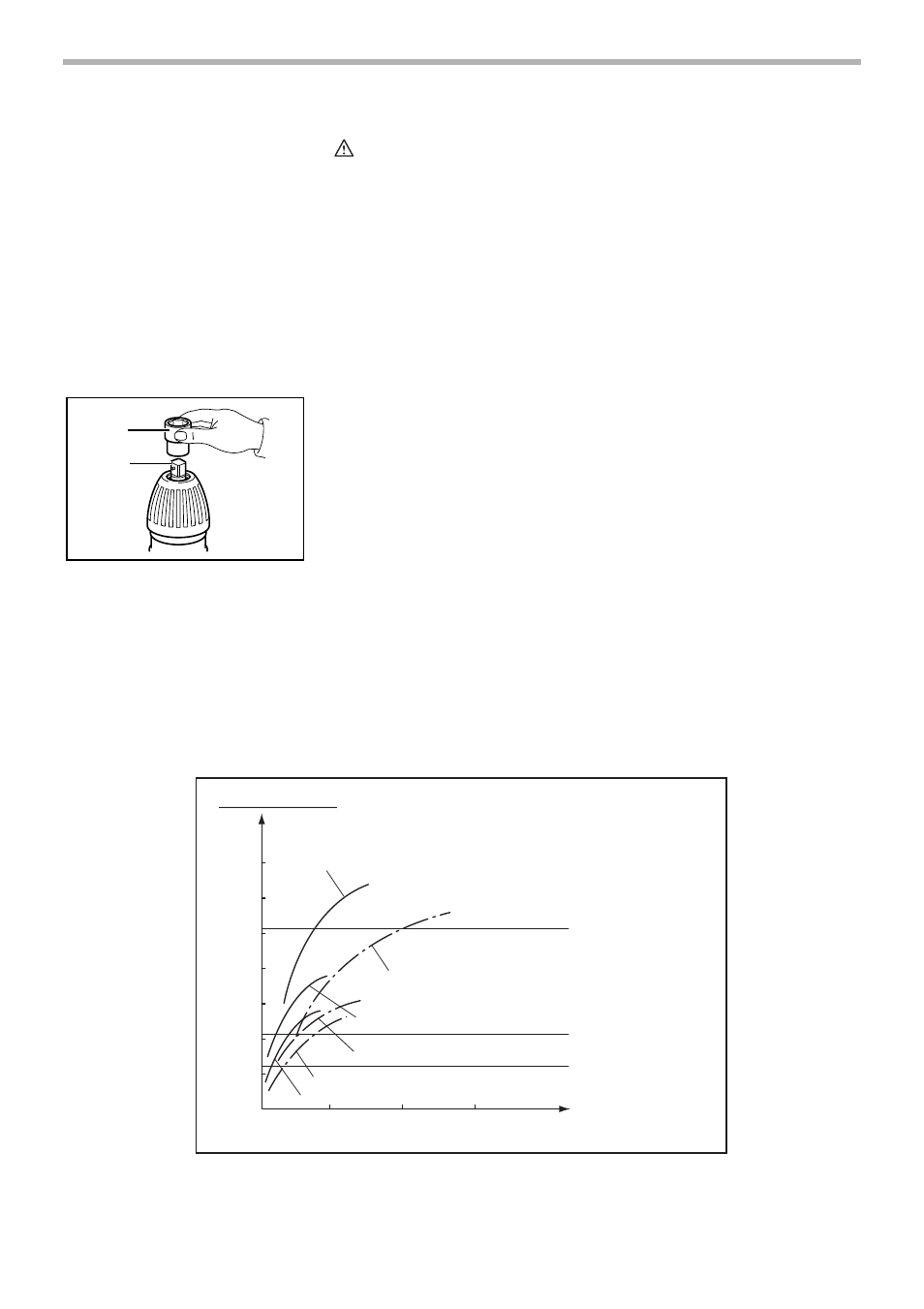

The proper fastening torque may differ depending upon the

kind or size of the bolt, the material of the workpiece to be

fastened, etc. The relation between fastening torque and fas-

tening time is shown in the figures.

1. Socket

2. Anvil

1

2

002335

N.m

(ft.lbs)

140

(101)

120

(87)

100

(72)

80

(58)

60

(43)

40

(29)

20

(14)

0

1

2

3

(S)

M16X50 (5/8” X 2”) at high speed

M16 (5/8”)

M16X50 (5/8” X 2”) at low speed

M12X50 (1/2” X 2”) at high speed

M12X50 (1/2” X 2”) at low speed

M10X50 (3/8” X 2”) at low speed

M10X50 (3/8” X 2”) at high speed

M12 (1/2”)

M10 (3/8”)

Fastening time

F

astening torque

Standard bolt

Proper f

astening torque