Warning – Milwaukee RAVL42 User Manual

Page 34

34

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Vent Pipe Maintenance

Conduct an inspection of the venting system semi-annually. Recom-

mended areas to inspect are as follows:

1. Check areas of the venting system which are exposed to the elements

for corrosion. These will appear as rust spots, streaks, or in extreme

cases, holes. These components should be replaced immediately.

2. Remove the cap and shine a flashlight down the vent. Remove any

bird nests or other foreign material.

3. Check for evidence of excessive condensate, such as water droplets

forming in the inner liner and subsequently dripping out at joints.

Continuous condensate can cause corrosion of caps, pipe and fittings.

It may be caused by having excessive lateral runs, too many elbows,

or exterior portions of the system being exposed to cold weather.

4. Inspect joints to verify that no pipe sections or fittings have been dis-

turbed and consequently loosened. Also check mechanical supports

such as wall straps or plumbers’ tape for rigidity.

CAUTION: Wear gloves and safety glasses for protection while

doing required maintenance.

Verify proper operation after servicing.

S'assurer que l'appareil fonctionne adéquatement une fois

l'entretien terminé.

Maintenance Checklist

The following should only be performed by a qualified service techni-

cian.

1. Annual inspection should be made and the following checks per-

formed:

o

When unit is cool, glass viewing door and inspect burner for dirt, soot

and lint accumulations and remove if necessary. If excessive soot ac-

cumulation is present on burner, have a qualified service technician

adjust the burner for proper combustion.

o

Clean inside of glass with gas fireplace glass cleaner. NEVER attempt

to remove or clean the glass when the unit is hot.

o

Check the hot air outlet vents for lint or other accumulations. Never

block or restrict vent openings, obstruct flow of ventilation air, or use

vents other than those approved for use with this appliance.

o

Check that direct-vent pipe, air intake and flue are open and free of

soot, blockage, or debris.

o

Check gaskets once a year. Gaskets must be tight. Replace if neces-

sary.

o

Inspect the pilot system for proper flame. NEVER ADJUST THE PILOT

until after the gas pressure has been checked and supply lines have

been completely bled (this may take an hour or more when bleeding

through the pilot). All pilots are checked and burned at the factory prior

to shipment. The pilot adjustment screw is located to the upper right

of the flame height control knob. Adjust the pilot screw to properly

size the flames. Flames should completely surround the thermopile

and thermocouple and extend across the main burner tube ports. Be

careful not to back the screw out of its threads. Check for gas leaks

using a gas leak test solution.

o

Check that the area around the fireplace is kept clear and is free of

combustible materials, gasoline and other flammable vapors and

liquids.

o

Check the millivolt system as per the table on this page.

2. The viewing glass should be cleaned periodically (see Glass Main-

tenance).

3. Should repairs or maintenance of the fireplace require the disas-

sembly of the vent/air intake system, the reassembly and resealing

should be completed by a qualified service technician and follow

the instructions on Page 17 of this manual.

Millivolt and System Checks

Check

Test

To

Test

Connect

Meter

Leads to

Terminals

Thermostat

Connects

Meter Read-

ing

Should Be

A

Complete

System

2 & 3

Closed

100 MV

or More

B

Thermopile

Output

1 & 2

Open

Greater Than

325 MV

C

System

Resistance

2 & 3

Closed

2.5 Ohms

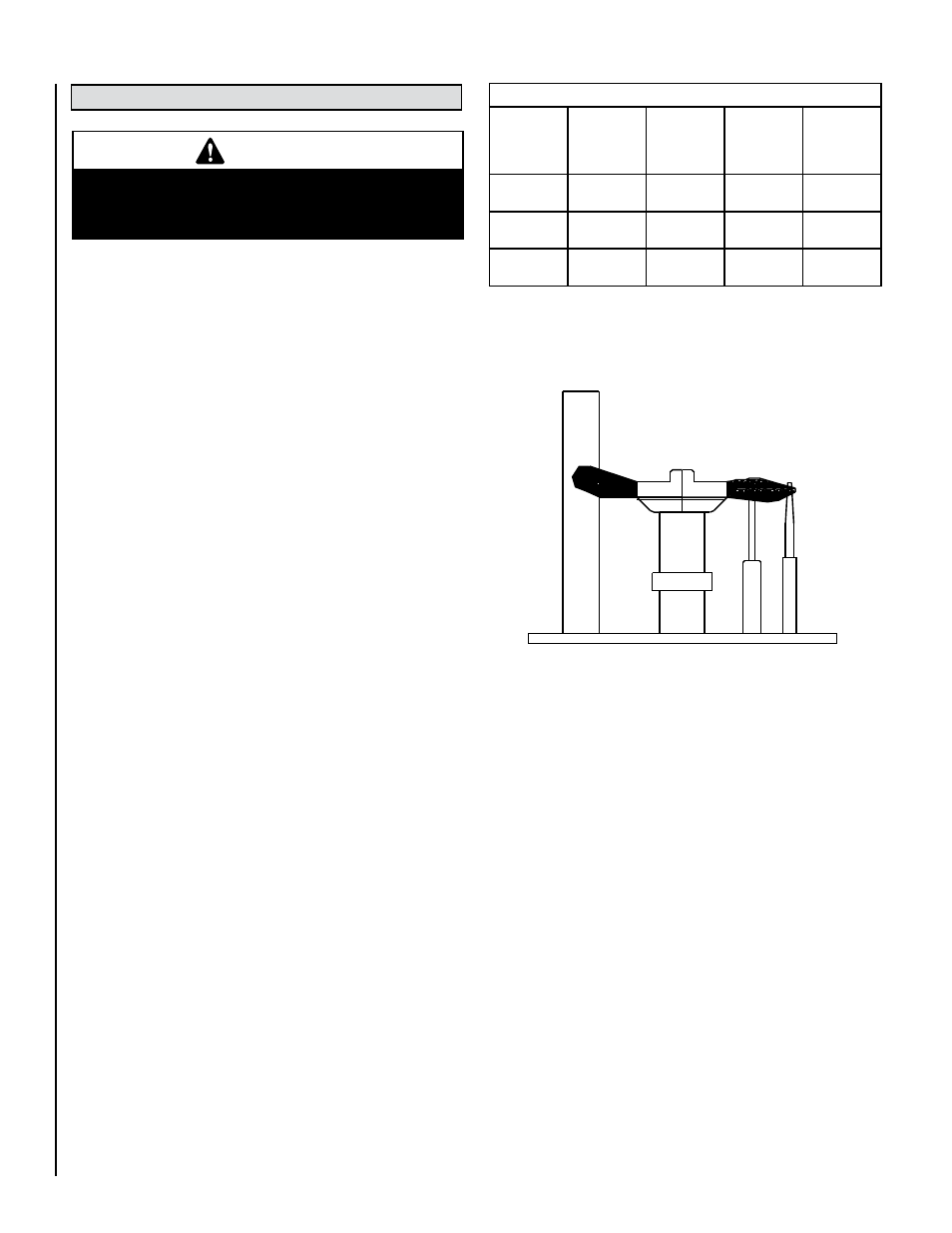

Proper Pilot Flame Appearance

Figure 48

MAINTENANCE AND SERVICING

WARNING

Turn off gas and electrical power to the fireplace

and allow it to cool before cleaning or servicing

the appliance.