Makita LS1011N User Manual

Page 22

22

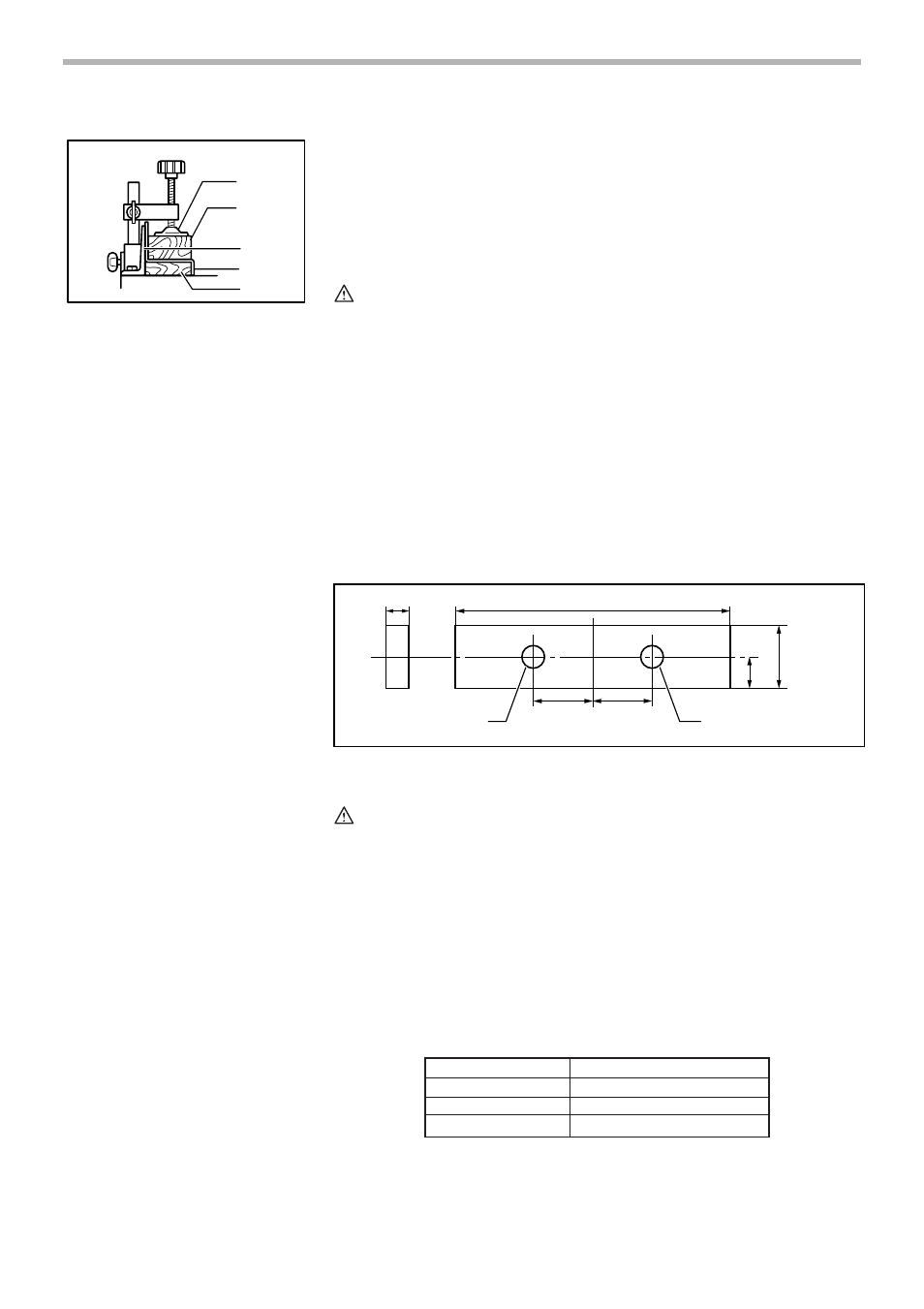

7. Cutting aluminum extrusion

When securing aluminum extrusions, use spacer blocks

or pieces of scrap as shown in the figure to prevent

deformation of the aluminum. Use a cutting lubricant

when cutting the aluminum extrusion to prevent build-up

of the aluminum material on the blade.

CAUTION:

•

Never attempt to cut thick or round aluminum extrusions.

Thick aluminum extrusions may come loose during

operation and round aluminum extrusions cannot be

secured firmly with this tool.

8. Wood facing

Use of wood facing helps to assure splinter-free cuts in

workpieces. Attach a wood facing to the guide fence

using the holes in the guide fence.

See the figure concerning the dimensions for a sug-

gested wood facing.

CAUTION:

•

Use straight wood of even thickness as the wood facing.

•

When cutting workpieces from 75 mm (2-15/16”) to

90 mm (3-1/2”) high, use a wood facing to prevent a

portion of the workpiece near the guide fence from being

left uncut.

Example:

When cutting workpieces 90 mm (3-1/2”) high, use

a wood facing with the following thickness.

1. Vise

2. Spacer block

3. Guide fence

4. Aluminum extrusion

5. Spacer block

1

2

3

4

5

001844

1. Hole

117mm

(4-5/8”)

Over 10mm (3/8”)

Over 500mm (19-11/16”)

117mm

(4-5/8”)

25mm

(1”)

75-90mm

(2-15/16”

-3-1/2”)

1

1

002182

Miter angle

0˚

45˚

57˚

Thickness of wood facing

Over 33 mm (1-5/16”)

Over 25 mm (1”)

Over 20 mm (13/16”)