Milwaukee 4005-55 User Manual

Page 2

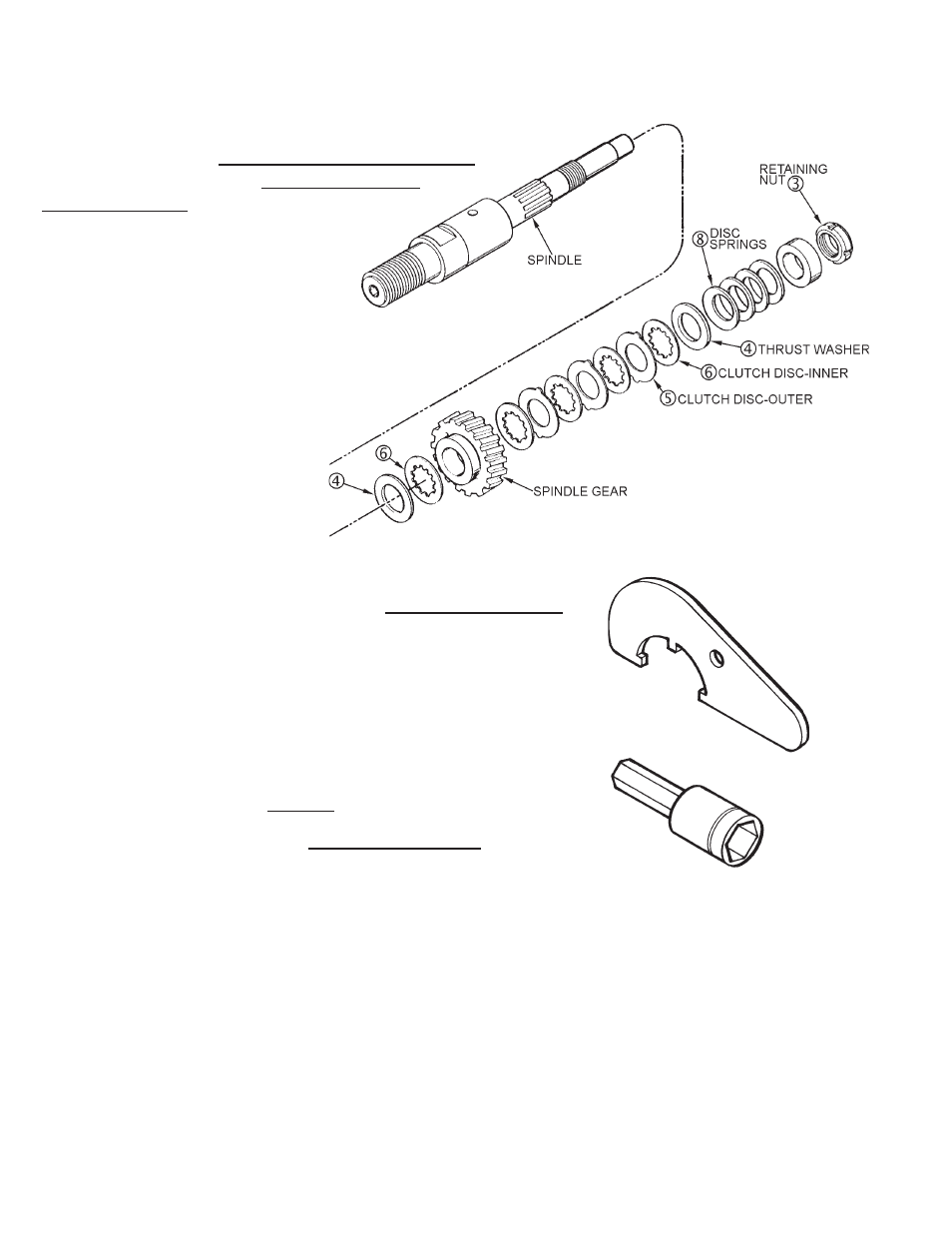

Servicing the Clutch Mechanism-

Torque Value for the Clutch Mechanism Retaining Nut (fi g. no. 3).

Grease / Lubrication — when assembling the internal clutch component parts:

the Clutch Discs (fi g. nos. 5 and 6), Thrust Washers (fi g. no. 4) and

Disc Springs (fi g. no. 8) are to be lightly coated with grease

(Cat. No. 49-08-4220 type ‘J’) during their assembly

into the spindle gear.

Grease / Lubrication specifi cation includes

coating internal bore of the spindle gear.

4 45-88-1140 Thrust Washers

(2)

5 43-06-0160 Clutch Discs-Outer (3)

6 43-06-0150 Clutch Discs-Inner (5)

8 40-50-2150 Spring Discs

(4)

32-75-3430 Spindle Gear

(1)

Service note: the assembly torque for the Clutch Mechanism Retaining Nut,

No. 06-57-1050 (fi g. no. 3), which insures the static torque required to slip

the clutch mechanism, as lubricated, should be 25-30 ft-lbs (34-41 Nm).

With the gear case separated from the diaphragm & motor housing of the

Clutch Dymo-Drill motor —

•

insert & engage a 61-10-0660 retaining nut spanner with the notches

in

the

06-57-1050 clutch adjustment retaining nut.

•

with a 1/2" hex socket bit driver attached to a torque wrench,

interlock the male hex with the female hex found in the threaded end

of the dymo-drill spindle.

•

turn the torque wrench clockwise

3, observing the torque reading

and tighten the clutch adjustment retaining nut on the rear of the

spindle

shaft until a value of 25-30 ft-lbs (34-41 Nm) is obtained.

Retaining Nut Spanner

Service Tool

No. 61-10-0660

1/2" Hex Bit Socket Driver,

Snap-On #psa16,

Pronto #5441½

or equivalent