Milwaukee LOK-TOR II User Manual

Page 5

8

9

OPERATION

WARNING

To reduce the risk of injury, wear

safety goggles or glasses with side

shields.

WARNING

Always remove battery pack before

changing or removing accessories.

Only use accessories specifically

recommended for this tool. Others

may be hazardous.

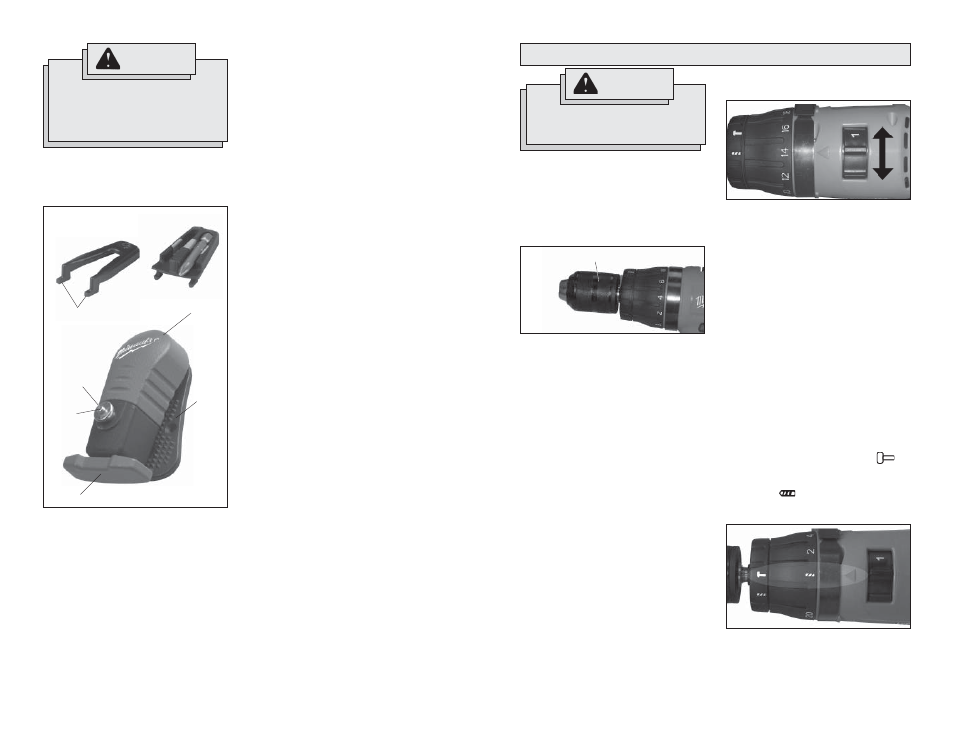

Bit holder

Clip-Lok

TM

System (Fig. 3)

The Clip-Lok system consists of three

pieces; the belt clip, the tool holder, and the

bit holder.

The system is shipped assembled for right-

handed use. To change the assembly for

left-handed use:

1. Remove battery pack.

2. Remove screws holding the tool holder

and the bit holder.

3. Lift the holders at the narrow end and

pull the front tangs out of their slots.

4. Replace the pieces onto the desired

side by sliding the tangs into the slots.

Tighten the screws securely.

Fig. 3

Attaching the Belt Clip

(Fig. 3)

The belt clip can be mounted to tool belts,

bags, buckets, etc. To mount the belt clip:

1. Pull up the clamp release. The clamp

will pop out.

2. Slide the clamp over the tool belt, bag,

bucket, etc.

3. Press in the clamp to tighten.

Using the Clip-Lok Tool Holder

1. To attach the tool to the belt clip, slide

the tool holder over the stud on the belt

clip until it is held in place by the protrud-

ing pin.

2. To

release the tool from the belt clip,

grasp the tool handle, push down on

the tool release lever with your thumb,

and pull up on the tool.

Using the Clip-Lok Bit Holder

The bit holder holds two standard 1/4" hex

shank bits up to two inches long.

1. Insert the bit by pressing it into the

clip.

2. Remove the bit by lifting the tip of the

bit and pulling it out of the clip.

Belt clip

Tool release lever

Stud

Pin

Clamp

Clamp

release

Tool holder

Front tangs

Selecting Speed (Fig. 5)

The speed selector is on top of the motor

housing. Allow the tool to come to a complete

stop before changing speeds. See “Ap-

plications” for recommended speeds under

various conditions.

1. For

Low speed (up to 500 RPM), push

the speed selector to the left.

2. For

High speed (up to 1700 RPM), push

the speed selector to the right.

Using Keyless Chucks (Fig. 4)

Your cordless tool is equipped with a spindle

lock. The chuck can be tightened with one

hand, creating higher grip strengths on the

bit.

Always remove the battery pack or lock the

trigger before inserting or removing bits.

1. To open the chuck jaws, turn the sleeve

in the counterclockwise direction.

When using drill bits, allow the bit to

strike the bottom of the chuck. Center

the bit in the chuck jaws and lift it about

1/16" off of the bottom.

When using screwdriver bits, insert the

bit far enough for the chuck jaws to grip

the hex of the bit.

2. To close the chuck jaws, turn the sleeve

in the clockwise direction. The bit is se-

cure when the chuck makes a ratcheting

sound and the sleeve can not be rotated

any further.

3. To remove the bit, turn the sleeve in the

counterclockwise direction.

NOTE: A ratcheting sound may be heard

when the chuck is opened or closed. This

noise is part of the locking feature, and

does not indicate a problem with the chuck's

operation.

Fig. 4

Sleeve

Fig. 6

To Hammer

Fig. 5

Low

High

Selecting Hammer or Drill Action

(Fig. 6, 7 & 8)

MILWAUKEE Hammer-Drills are designed

for three operating modes: drilling with

hammering action, drilling only, and driving

screws. To set the operating mode, rotate

the hammer/drill selector collar and torque

selector collar to the desired symbols.

1. To use the hammer-drilling mode

(Fig. 6), rotate the hammer/drill selector

collar until the hammer symbol ap-

pears in line with the arrow. Then rotate

the Torque selector collar until the drill

symbol appears in line with the ar-

row. Apply pressure to the bit to engage

the hammering mechanism.

NOTE:

When using carbide bits, do not

use water to settle dust. Do not attempt

to drill through steel reinforcing rods.

This will damage the carbide bits.