5. control board pc1 test point values – Miller Electric SYNCROWAVE 250 TM-353E User Manual

Page 35

TM-353 Page 31

Syncrowave 250

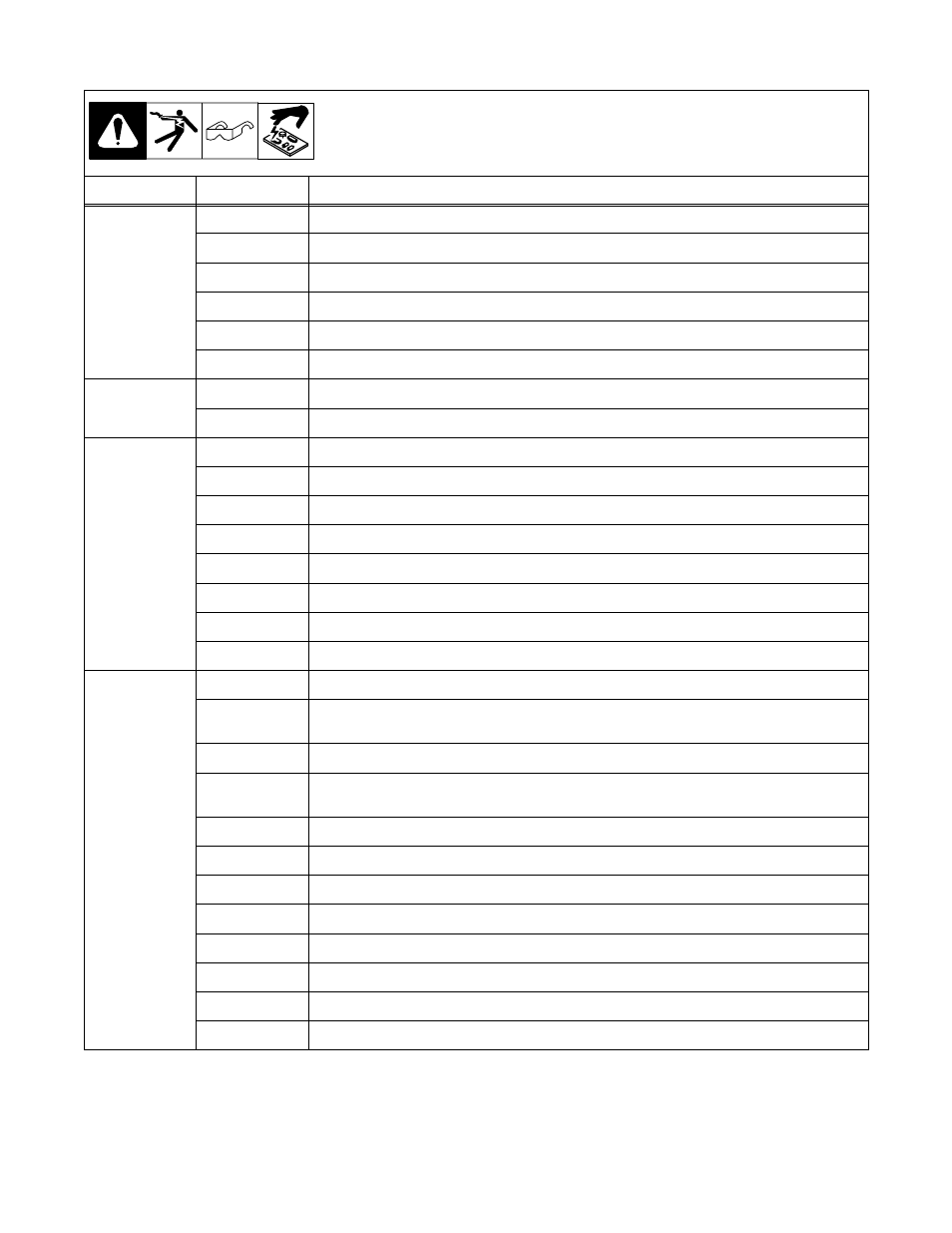

6-5.

Control Board PC1 Test Point Values

PC1 Voltage Readings

a) Tolerance –

±

10% unless

specified

b) Reference – to circuit common

(lead 42) unless noted

Receptacle

Pin

Value

RC51

1

18 volts ac input

2

18 volts ac input

3

+10 volts dc output

4

Circuit common

5

Not used

6

Not used

RC52

1

Circuit common

2

+1 millivolt dc per 3 ampere of weld output

RC53

1

Gate pulse for SCR1 with respect to pin 2 (see Section 6-3)

2

Reference for gate pulse to SCR1

3

Gate pulse for SCR3 with respect to pin 4 (see Section 6-3)

4

Reference for gate pulse to SCR3

5

Gate pulse for SCR2 with respect to pin 6 (see Section 6-3)

6

Reference for gate pulse to SCR2

7

Gate pulse for SCR4 with respect to pin 8 (see Section 6-3)

8

Reference for gate pulse to SCR4

RC54

1

Not used

2

0 to +10 volts dc input from min. to max. of Amperage Adjustment control R1 with Amperage Control

switch S5 in Panel position, and contactor on

3

0 volts with Output (Contactor) switch S3 in On position or +7.8 volts dc with S3 in Remote position

4

0 to +10 volts dc input from min. to max. of Crater Control R11 with Crater Fill switch S7 in On posi-

tion, or +10 volts dc with S7 in Off position

5

+10 volts dc output with Output (Contactor) switch S3 in On position

6

–24 volts dc

7

–24 volts dc with contactor on or off

8

0 to +10 volts dc input from min. to max. of Amperage Adjustment control R1 with contactor on

9

0 to +10 volts dc input from min. to max. of Amperage Adjustment control R1 with contactor on

10

Circuit common

11

+24 volts dc

12

0 volts during open-circuit voltage condition; +24 volts with arc on or contactor off