Figure 3-2.2 – Murphy A900 Series User Manual

Page 7

(d) Overcrank circuit; will stop automatic cranking and

indicate overcrank if engine fails to start after 3 attempts.

The number of cranks are selectable for 1, 2, 3, 4 or 5

cycles before shutdown. The overcrank circuit may also

be turned off so no overcrank shutdown occurs.

(e) Shutdown Time Delay Bypass; this delay prevents the oil

pressure, water temperature and loss of speed signal

shutdown circuits from operating for 15 seconds after the

engine starts as detected by the crank disconnect circuit.

This same delay also locks out the Low Oil Pressure Pre-

alarm and High Water Temperature Pre-alarm circuits

when the engine is not running.

(f) Overspeed Speed Switch;

1. Provides a signal to the overspeed shutdown circuit if

the engine exceeds the preset speed. The factory

setting is approximately 3894 Hz, or 1980 RPM on an

engine with 118 teeth on the flywheel ring gear. The

adjustment range is 300 Hz to 10,000 Hz.

2. A push-to-test switch is provided to allow testing of the

overspeed circuit without overspeeding the engine.

When switch is depressed, the set point of the speed

switch is lowered approximately 10%.

3. The push-to-test switch can also be used to set the

overspeed switch at approximately 110% of running

speed. Hold the switch depressed while adjusting the

setting until the overspeed trips. When switch is

released, the set point will be 10% above normal running

speed. This is the method used to make the factory

setting. With engine speed at 1800 RPM or 3540 Hz.

(g) Cooldown circuit; this circuit keeps the engine running

for five minutes after the transfer switch has removed

the load from the generator and signaled the A901 to

stop the engine. This feature may be selected (turned

On, standard setting is Off) with a switch on the back of

the Control / Display Module.

3-2.1.5 Seven (7) First-out Shutdown Circuits; provide first-out

indication of cause of shutdown. These circuits deactivate the

fuel relay and lockout the A901 until reset. Shutdown circuits

are activated by the crank disconnect circuit and are not active

when the engine is stopped. Six (6) Red Shutdown Indicating

Lights are provided. The Remote Shutdown circuit does not

have an indicator light.

(a) Overcrank; tripped by the overcrank sensing circuit which

counts the number of cranking attempts.

(b) Overspeed; tripped by overspeed switch when engine

exceeds a preset speed.

(c) Oil Pressure; tripped by the oil pressure SWICHGAGE

®

if pressure drops below preset point while the engine is

running.

(d) Water Temperature; tripped by the water temperature

SWICHGAGE

®

if engine coolant temperature exceeds the

switch setting.

(e) Spare Shutdown; tripped by an external switch. This

circuit is provided for an additional shutdown that may be

recommended by the engine supplier.

(f) Loss of Speed Signal; tripped by an internal sensing

circuit that detects the loss of the Magnetic Pickup

frequency signal for the speed switches while the engine

is still running. Since the Overspeed shutdown circuit is

activated by the frequency input, it prevents the engine

from running without overspeed protection.

(g) Remote Shutdown; this circuit is provided to shutdown

the engine generator from a remote location. No

indicating light is provided.

3-2.1.6 Nine (9) Alarm Indicating Circuits; provide indication of

cause of alarm. These circuits activate the alarm relays. Alarm

circuits are active as long as power is applied to the A901. All are

active when the engine is running, shutdown or on standby except

Low Oil Pressure Pre- alarm and High Water Temperature Pre-

alarm. Nine (9) Amber Alarm Indicating Lights are provided.

(a) Low Water Temperature; operated by low water temp-

erature SWICHGAGE

®

.

(b) Spare Alarm; operated by an external switch. This circuit

is provided for an additional alarm that may be required by

the user.

(c) Switch Not In Automatic; operated by the OFF-AUTO-

TEST mode selector switch.

(d) Low Fuel Level; operated by level switch on fuel tank.

(e) High Battery Voltage; operated by relay contact in

battery charger.

(f) Low Battery Voltage; operated by low voltage sensing

device in battery charger.

(g) Low Oil Pressure Pre-alarm; operated by pre-alarm

switch in oil pressure SWICHGAGE

®

.

(h) High Water Temperature Pre-alarm; operated by pre

alarm switch in water temperature SWICHGAGE

®

.

(i) Battery Charger AC Failure: operated by a relay contact in

the Battery Charger.

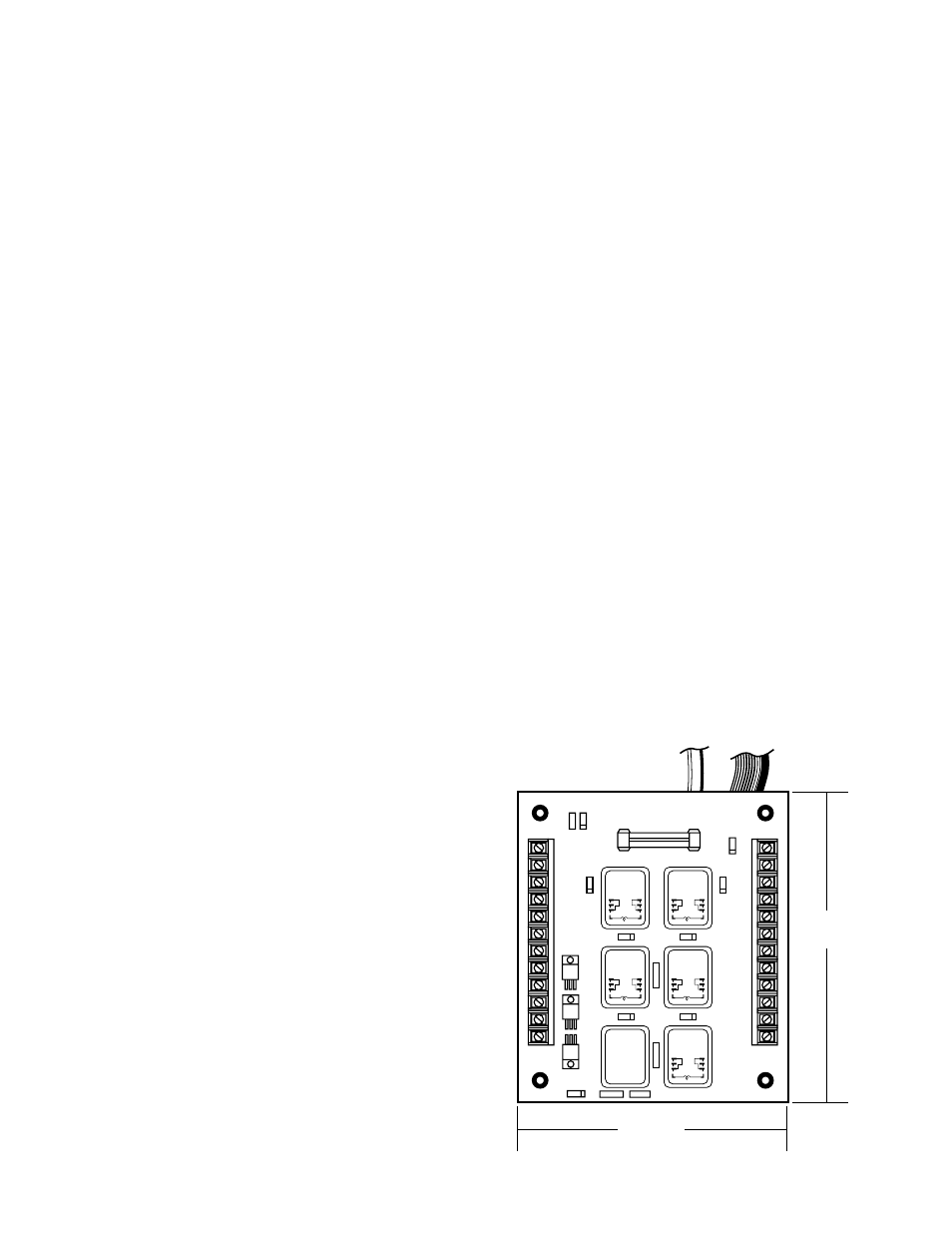

3-2.2 Relay Module. The Relay Module, figure 3-2.2, includes

all of the control, alarm and shutdown relays that are required to

make up the generator engine control. Relays are available for

operation on either 12 or 24 volt battery systems. Five (5) relays

are included for:

3-2.2.1 Fuel Relay; this relay provides two outputs, one to

energize the engine fuel solenoid and a separate circuit to

4

DC12V

3A Fuse

1A

4

5

6

7

8

9

16

17

18

19

20

21

22

23

24

25

RH2V2

-U

DC12V

RH2V2

-U

DC12V

RH2V2

-U

DC12V

RH2V2

-U

DC12V

RH2V2

-U

6-1/4 in.

(159 mm)

4-1/2 in.

(114 mm)

Figure 3-2.2