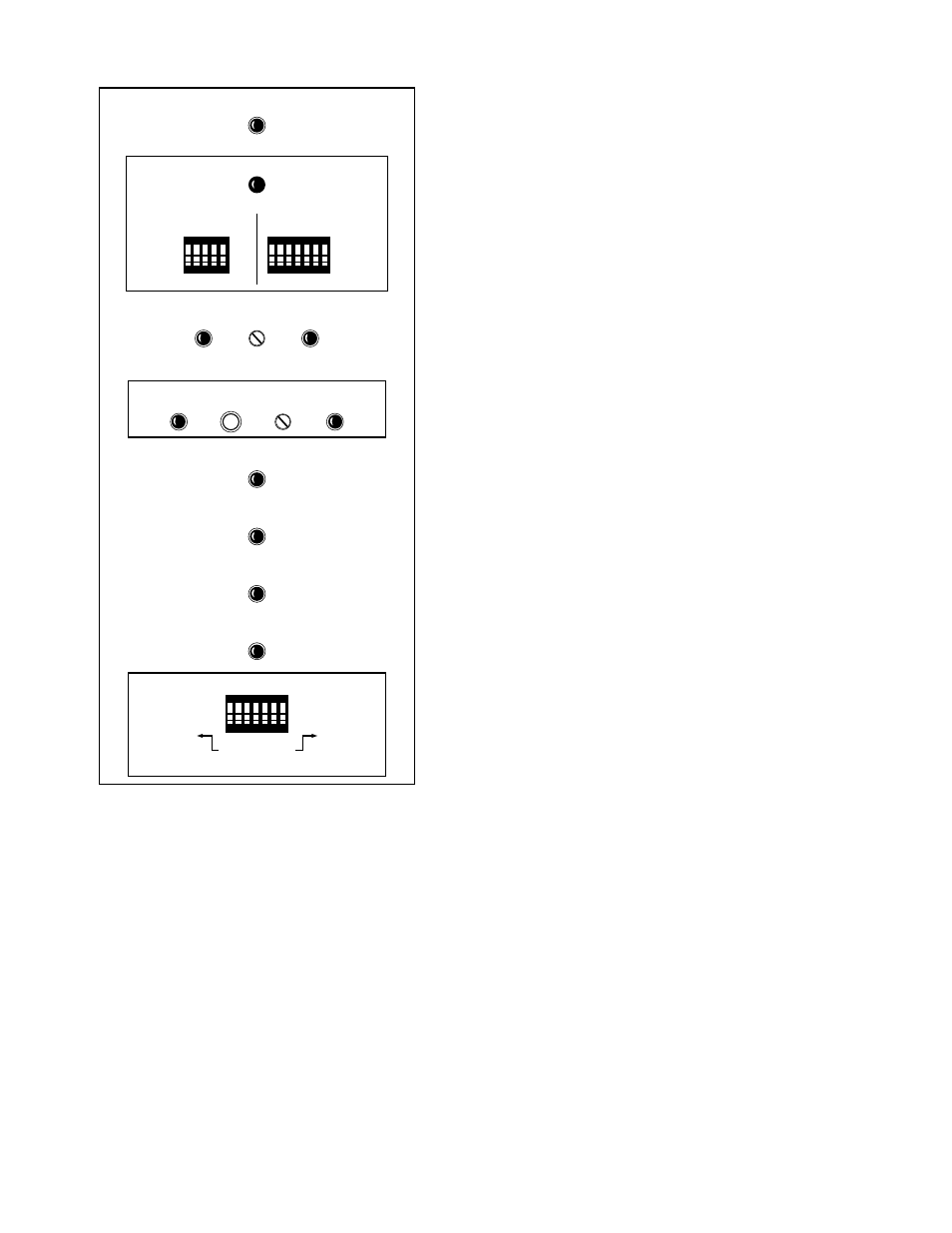

Figure 4-4.1.3 – Murphy A900 Series User Manual

Page 23

6. While engine is cranking, turn crank disconnect

adjustment counter clockwise slowly until “Crank

Disconnect Speed” light turns on and cranking stops.

7. Turn crank disconnect adjustment clockwise 1/4 turn.

This sets crank disconnect speed at approximately 125

RPM above cranking speed.

8. Turn Mode Selector switch OFF.

(f) Reconnect the run solenoid wire at terminal 6 on Relay

Module.

4-4.3 Start and Stop Engine; to test the start and stop function,

proceed as follows:

(a) Double check all wiring to be sure it is connected.

(b) Turn Mode Selector switch to the TEST position. This

gives the A900 Controller a start signal.

(c) Engine should crank, start and come up to governor speed.

1. Check “Crank Disconnect Speed” light; it should be on

and “Crank Relay” light should be off.

2. If lights are not correct, turn Mode Selector switch

OFF and review paragraph 4-4.2.

(d) When engine has come up to speed and governor has been

adjusted for proper running speed, turn Mode Selector

switch OFF. This gives the A900 Controller a stop signal.

(e) All lights on the back of the A900 should go off and the

engine stop. If engine does not stop, check run solenoid

to be sure it has returned to the stop position.

4-4.4 Automatic Start and Stop; to test the automatic-start and

stop function, proceed as follows:

(a) Turn Mode Selector switch to the AUTO position. Short

terminal 28 to 4 on the Control / Display module. This

gives the A900 Controller a start signal.

(b) Engine will crank, start and come up to governor speed.

(c) When engine has come up to speed, open the circuit

between terminal 28 and 4. This gives the A900

Controller a stop signal.

(d) All lights on the back of the A900 should go off and the

engine stop.

4-4.5 Overspeed Switch Setting; To set the speed switch,

proceed as follows:

(a) Turn Mode Selector switch to the TEST position.

(b) Engine will crank, start and come up to governor speed.

(c) With engine running, adjust governor to bring engine speed

to normal RPM.

(d) Depress and hold the Overspeed Test pushbutton.

(e) Slowly turn the Overspeed Set adjustment counter-

clockwise until the “Overspeed” and “Overspeed Relay”

lights on the A900 come on and the engine shuts down.

(f) Release pushbutton; check “Overspeed” light on front

panel to be sure it is on.

(g) Turn Mode Selector switch OFF to reset shutdown circuits;

then back to TEST.

(h) When engine starts, increase governor speed setting slowly

until engine shuts down on overspeed. This should occur

about 10% above governor speed.

(i) Turn Mode Selector switch OFF.

4-4.6 Overcrank setting; to test number of cranks before system

shuts down on overcrank;

(a) Disconnect the run solenoid wire from terminal 6 of the

Relay Module.

(b) Check number set on the “Number Of Cranks” switch on

A900 back panel. It is factory set at 3.

(c) Turn Mode Selector switch to TEST.

1. Engine will crank for 15 seconds.

2. Then rest for 15 seconds

3. This should repeat 3 times and then the “Overcrank”

light on the A900 will come on and engine will not

crank again.

(d) Turn Mode Selector switch OFF.

(e) Reconnect the run solenoid wire at terminal 6 of the Relay

Module.

4-4.7 Oil Pressure; to test oil pressure shutdown circuit:

(a) Turn Mode Selector switch to TEST. When engine starts,

wait 30 seconds then,

(b) Use a jumper wire and short from terminal 30 to 4.

(c) “Oil Pressure” light will come on and engine will stop.

(d) Turn Mode Selector switch OFF.

4-4.8 Water Temperature; to test the water temperature

shutdown circuit:

(a) Turn Mode Selector switch to TEST. When engine starts,

wait 30 seconds then,

(b) Use a jumper wire and short from terminal 32 to 4.

20

Fuel Relay

Crank Relay

Crank/Rest

Time

Number

of Cranks

Close Only One Switch

Close Only One Switch

Pickup

Present

Crank

Disconnect

Set

Crank

Disconnect

Speed

SW1 = 10 s.

SW2 = 15 s.

SW3 = 20 s.

SW4 = 25 s.

SW5 = 30 s.

Torque

Scews to

12 In./lb.

15

26

04

27

28

04

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

53

54

55

56

57

58

47

48

49

50

51

52

Overspeed Overspeed

Test

Overspeed

Set

Overspeed

Relay

Shutdown

Relay

Local Audible Alarm

Relay

Remote Visual Alarm

Relay

Remote Audible Alarm

Relay

Miscellaneous Program Switches

5 min. Cooldown

Unused Switches

SW1 = Open

SW2

Alarm

SW3 = Closed

SW4 = Open

SW5 = Open

SW6 = Closed

Shutdown

SW3 = Open

SW4 = Closed

SW5 = Closed

SW6 = Open

Air Damper Closed

Light ON With

Overspeed Shutdown

SW7= Closed

Loss of Speed Circuit

Torque

Scews to

12 In./lb.

40-05-0400

SW1 = 1

SW2 = 2

SW3 = 3

SW4 = 4

SW5 = 5

SW6

SW7 = None

Unused

Switch

SW6

1 2 3 4 5 6 7

1 2 3 4 5 6 7

1 2 3 4 5

Figure 4-4.1.3