Changing the friction wheel, Remove the wheels from the axle, Figure 22 – MTD 770-10278 993 User Manual

Page 13: Figure 23, Note, Caution, Section 10: off-season storage, Warning, Store in a clean, dry area

13

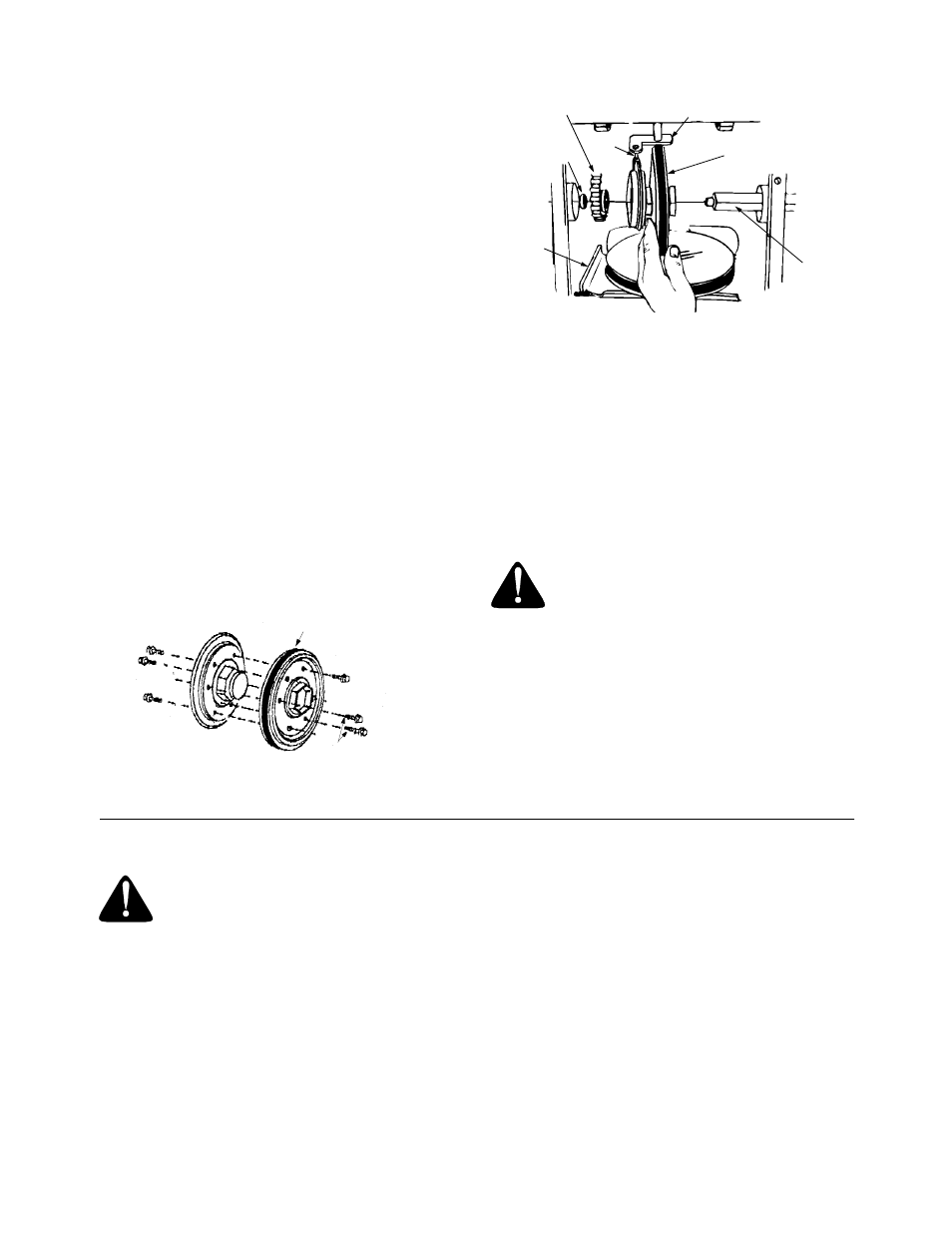

Changing the Friction Wheel

The rubber on the friction wheel is subject to wear

and should be checked after 25 hours of operation,

and periodically thereafter. Replace the friction

wheel rubber if signs of excessive wear or cracking

are found.

1.

Drain the gasoline from the snow thrower, or

place a piece of plastic under the gas cap.

2.

Tip the snow thrower up and forward, so that it

rests on the housing.

3.

Remove six self-tapping screws from the frame

cover underneath the snow thrower.

4.

Remove the wheels from the axle.

5.

Using a 7/8” wrench hold the hex shaft and

remove the hex bolts and cupped washer and

bearing from left side of the frame. See Figure

15. Hold the friction wheel assembly, and slide

the hex shaft out of the unit toward the right

hand side.

6.

Remove the six screws from the friction wheel

assembly (three from each side).

7.

Reassemble new bonded friction wheel rubber

to the friction wheel assembly, tighten the six

screws in rotation and with equal force. See

Figure 22.

Figure 22

Figure 23

8.

Position the friction wheel assembly up onto the

pin of the shift rod assembly and slide the shaft

through the friction wheel. See Figure 23.

9.

Slide the hex shaft into the hex I.D. of the

sprocket, the spacer and the left ball bearing and

secure with the bell washer and hex bolt.

NOTE:

Make sure the pin from the shift arm

assembly is assembled to the new friction wheel

assembly.

CAUTION:

Check engine and snow

thrower frequently for loose nuts, bolts, etc.

and keep these items tightened.

SECTION 10: OFF-SEASON STORAGE

WARNING:

Never store engine with fuel

in tank indoors or in poorly ventilated areas

where fuel fumes may reach an open

flame, spark or pilot light as on a furnace,

water heater, clothes dryer or other gas

appliance.

1.

If unit is to be stored over 30 days, prepare

engine for storage as instructed in the separate

engine manual included with your unit.

2.

Remove all dirt from exterior of engine and

equipment.

3.

Follow lubrication recommendations on page 10.

4.

Store in a clean, dry area.

NOTE:

When storing any type of power equipment

in an unventilated or metal storage shed, care

should be taken to rust proof the equipment. Using a

light oil or silicone, coat the equipment, especially

any chains, springs, bearings and cables.

Bonded Friction

Wheel Rubber

Hex Self-tapping

Screws

Spacer

Sprocket

Support

Pin

Bracket

Shaft

Shift Rod

Friction Wheel

Assembly

Assembly