GSW Electric Water Heater P/N 61515 REV. G (05-03) User Manual

Page 5

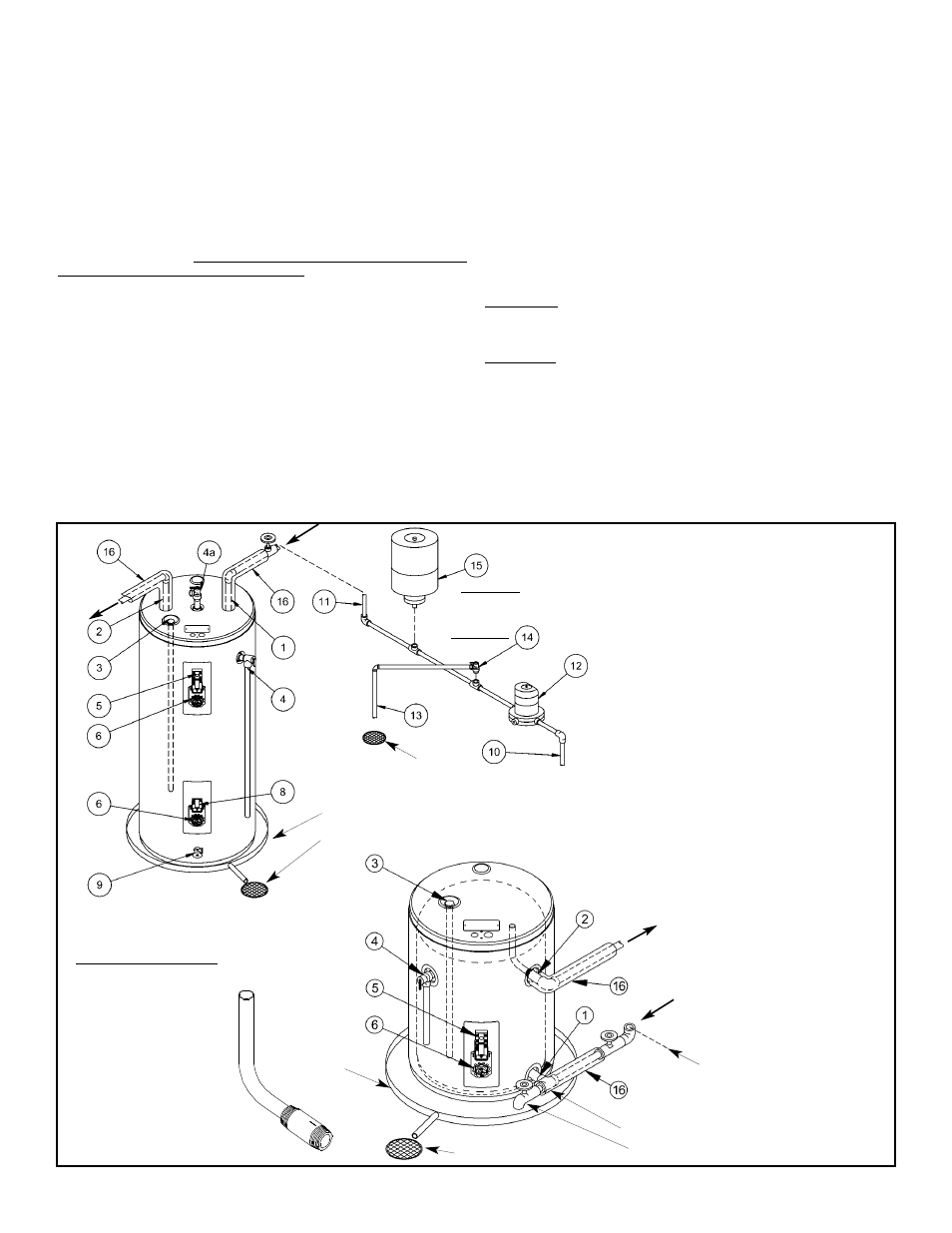

Tee fitting

Refer to pressure relief/expansion

tank schematic above.

OPTION 2

OPTION 1

A bent tube (as shown) is

installed for the hot water

outlet on side outlet water

heaters to ensure a maxi-

mum of hot water supply.

This fitting must be aligned

properly. The 'line' on the

fitting must be oriented

pointing up. When in correct

position, the hot water is

drawn from the highest

point in the tank.

SPACESAVER™ MODELS

(SIDE OUTLET) ONLY

NOTE TO INSTALLERS:

1. Cold water inlet

2. Hot water outlet

3. Anode(s)

4. Temperature and pressure (T&P) relief valve*

4a. Alternate location of T&P relief valve*

5. Thermostat with High-limit switch

6. Element

7. Access door - not illustrated

8. Thermostat

9. Drain valve

10. Water supply to meter

11. Water supply to water heater

12. Water meter with backflow preventer

13. Overflow

14. Pressure relief valve

15. Expansion tank

16. Pipe Insulation (mandatory if supplied with

heater)

*Items to be supplied by installer.

Options 1 and 2 show the location of pressure relief

and/or expansion tank if a check valve or pressure

reducing valve is in the cold water supply to the

house. Use option 1 or 2 as convenient. If a pressure

relief valve is used (OPTION 1) select one with a set-

ting 25 psi below the relief valve rating used on the

heater.

Also see

'Hot Water Odour' section.

·

A sudden appearance of rusty water can indicate the anode rod has been

depleted. The remaining steel core wire may be corroding, releasing

iron particles into the water. Inspect and replace as necessary. Also see

'Cathodic Protection: Anode Maintenance' section.

Water Heater Makes Noise

Sediment, sand or scale can accumulate resulting in "rumbling" or a

"hissing" noise. Water heaters need to be flushed regularly to minimize

buildup. Severe accumulations can cause premature failure of the water

heater elements.

Extended Non Use Service

Caution:

Hydrogen gas can be produced in a hot water system served

by this heater that has not been used for a long period of time (generally

two (2) weeks or more).

Hydrogen gas is extremely flammable and can

ignite when exposed to a spark or flame. To reduce the risk of injury

under these conditions, it is recommended that the hot water faucet be

opened for several minutes at the kitchen sink before using any electrical

appliance connected to the hot water system. Use caution in opening

faucets. When hydrogen is present, there will probably be an unusual

sound such as air escaping through the pipe as the water begins to flow.

There should be no smoking or open flame near the faucet at the time it

is open.

Pressure Build-Up (Thermal Expansion)

During the heating cycle of the water heater, the water expands creating

a pressure build-up in the plumbing system. If the pressure exceeds 150

PSI, water will come out of the valve. This is a normal safety function of

the T&P valve. The water supply meter may have a check valve or back

flow preventer inside. This can increase the possibility of pressure build-

up. Causes of discharge can be thermal expansion, excess system pres-

sure, too high a temperature setting on the thermostat or something in the

water heater causing excess temperatures in the heater.

Thermal Expansion: When water is heated it expands. For example, in

a 40-gallon water heater, water being heated to its thermostat setting will

end up expanding by approximately 1/2 gallon. This extra volume creat-

ed by the expansion has to go somewhere or pressure will dramatically

increase, such as when water is heated in a closed system. A good indi-

cation of thermal expansion is when the T&P valve releases about one

cup of water for every 10 gallons of heater capacity with each heating

cycle. The T&P valve is functioning properly when it relieves pressure

caused by thermal expansion, but frequent relief can result in a build up

of natural mineral deposits on the valve seat, rendering the valve inoper-

ative. Should this happen, the T&P valve needs to be replaced. To prevent

this 'T & P VALVE' from discharging hot water, the loss of energy and

reduce the possible build-up of lime in the 'T & P VALVE' there are two

(2) recommendations:

OPTION 1: Install a 125 PSI Pressure Relief (only) valve in the cold

water supply line. Make sure that the discharge of this valve is directed

to a drain to prevent water damage and it is protected from freezing,

OR

OPTION 2: Install an expansion tank on the cold water supply line. For

every 50 U.S. gallons of stored water, the expansion tank must have a

minimum capacity of 1.5 U.S. gallons.

Temperature Relief: The T&P valve will discharge varying amounts of

water, but typically more than you would experience from thermal expan-

sion. Check the temperature in relation to the setting on the thermostat

dial. A malfunctioning thermostat could cause the water to get too hot.

5

Drain pan*

Floor drain

Floor Drain

Drain pan*

Floor drain

Drain valve*

Cold in

Hot out

Cold in

Hot out