Electrical – Goodman Mfg Split Type Room Air Conditioner and Heat Pump 000 &12 User Manual

Page 7

7

2.

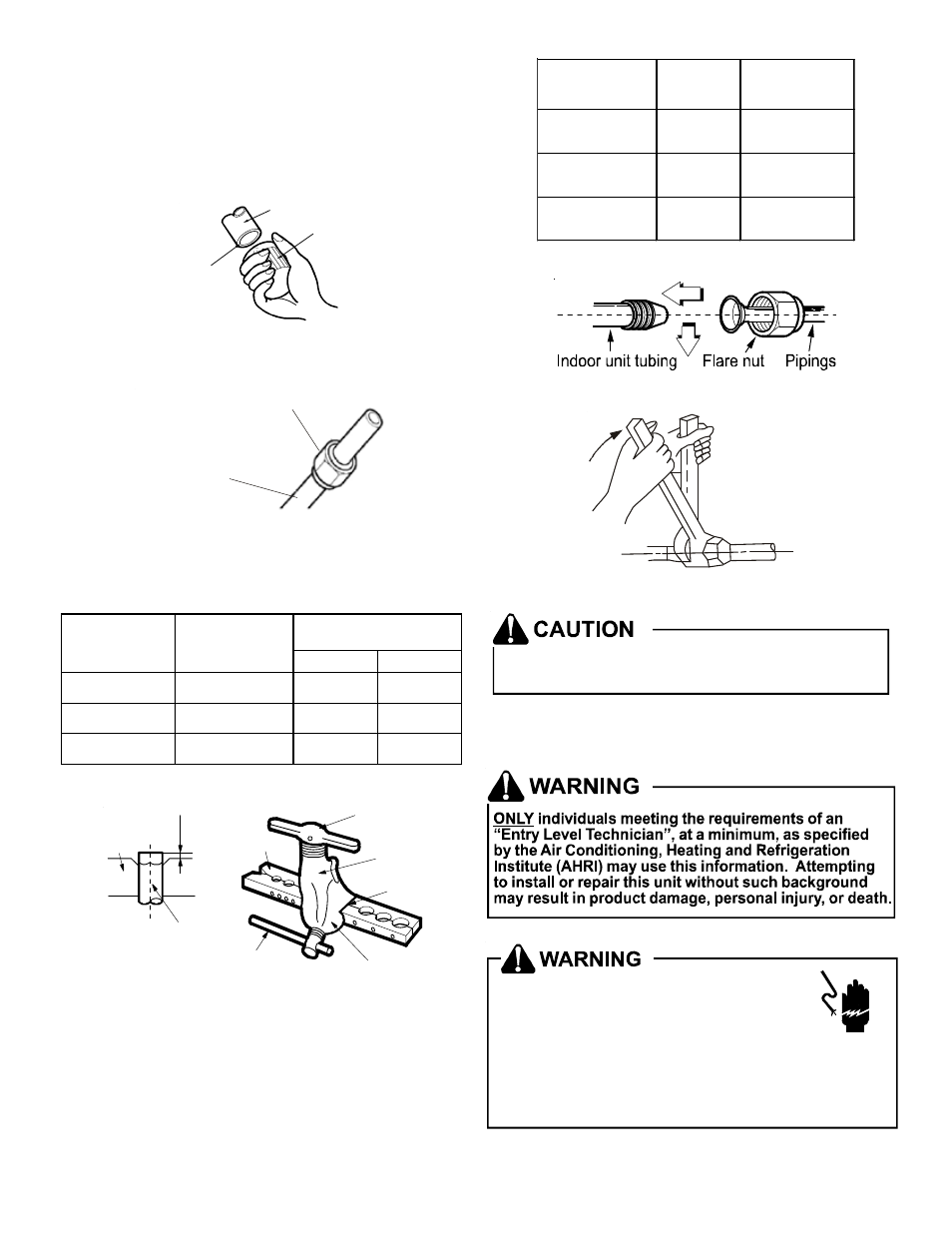

Insert tube in flare tool to measurement “A” in chart.

Flare tubing as shown in Figure 19. Make sure flare is

free of burrs and completely formed to make a leak proof

joint.

NOTE:

In order to avoid dropping burrs into the tubing,

angle the end of the copper tube/pipe in a downward

direction as you remove the burrs.

Pipe

Reamer

Point down

Figure 17

Flare nut

Copper tube

Figure 18

4. Flare Connections: Firmly hold the copper pipe in a die

with the dimensions as in the following table.

Max.

Min.

MS* 09 & 12

1/4" (Φ 6.35)

3/64" (1.3)

1/32" (0.7)

MS*09

3/8" (Φ 9.52)

1/16" (1.6)

3/64" (1.0)

MS*12

1/2" (Φ12.7)

1/16" (1.8)

3/64" (1.0)

A (inches & mm)

Outdoor

Diameter

(inches & mm)

Model

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A

"

Figure 19

5. Tightening the connection:

•

Align the center of the pipes and finger-tighten the flare

nut. Using a spanner and torque wrench (Figures 20 &

21) continue tightening the flare nut until the nut is firmly

on the pipe.

1/4" (Φ 6.35)

1500

(153kgf.cm)

1600

(163kgf.cm)

3/8" (Φ 9.52)

2500

(255kgf.cm)

2500

(265kgf.cm)

1/2" (Φ12.7)

2500

(255kgf.cm)

3600

(367kgf.cm)

Outdoor

Diameter (mm)

Tightening

Torque

(N. cm)

Additional

Tightening

Torque (N. cm)

Figure 20

Figure 21

Do not over-tighten. Excessive torque can

break the nut and/or crimp the pipe.

Electrical

HIGH VOLTAGE!

Disconnect ALL power before servicing or

installing this unit. Multiple power sources

may be present. Failure to do so may cause property

damage, personal injury or death due to electric shock.

Wiring must conform with NEC or CEC and all local

codes. Undersized wires could cause poor equipment

performance, equipment damage or fire.