Troubleshooting – Global Machinery Company ATI2K User Manual

Page 12

12

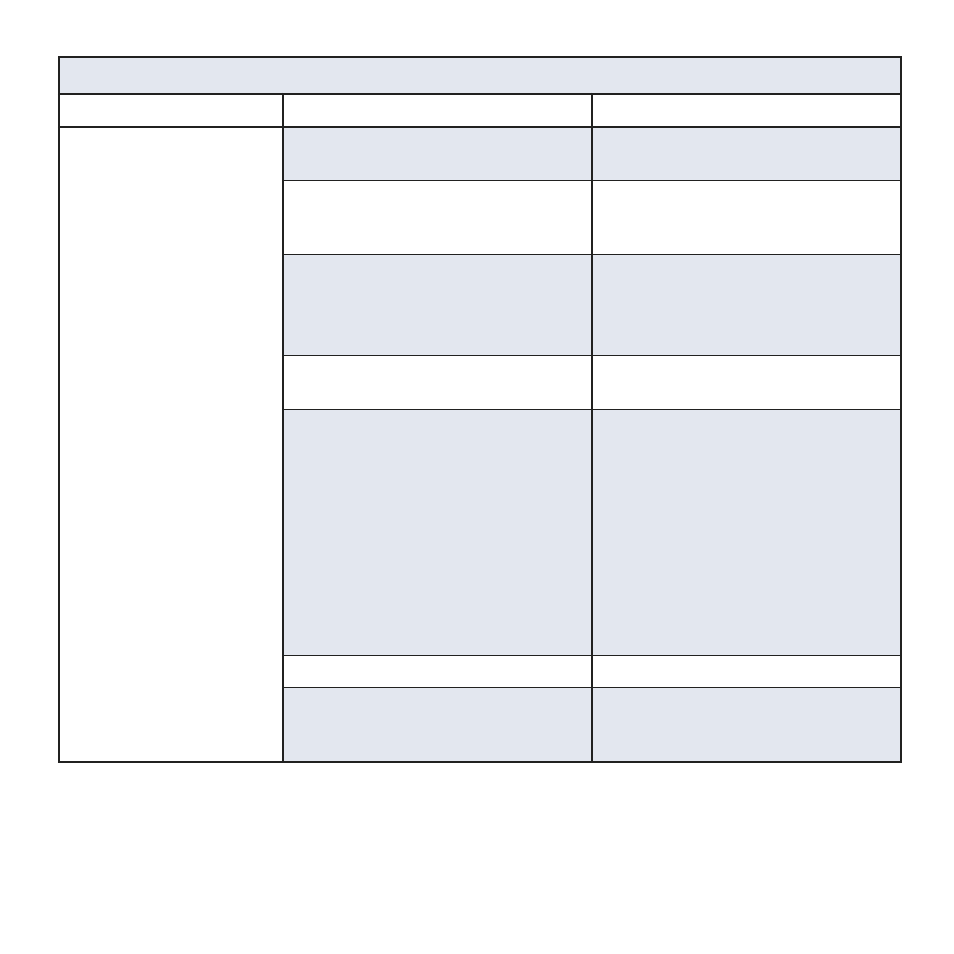

Troubleshooting

Trouble

Possible cause(s)

Suggested remedy(s)

Tool runs slowly or will not

operate.

1. No oil in tool.

1. Lubricate the tool according to the

lubrication instructions.

2. Grit or gum in tool.

2. Flush the tool with air tool oil, gum

solvent, or an equal mixture of motor

oil and kerosene.

3. Low air pressure.

3. a. Adjust the regulator on the tool to

the maximum setting.

b. Adjust the compressor regulator to tool

maximum the tool is running free.

4. Air hose leaks.

4. Tighten and seal hose fittings if leaks

are found.

5. Pressure drops.

5. a. Be sure the hose is the proper

size. Long hoses or tools using

large volumes of air may require

a hose with an I.D. of 1/2” or

larger depending on the total

length of the hose.

b. Do not use a multiple number of

hoses connected together with

quick connect fittings. This causes

additional pressure drops and

reduces the tool power.

6. Worn rotor blade.

6. Replace rotor blade.

7. Worn ball bearing.

7. Remove and inspect bearing for rust,

dirt and grit. Replace or clean and

regrease bearing with bearing grease.