Maintenance, Troubleshooting continued – Global Machinery Company AC30G User Manual

Page 14

Maintenance

1. After the first 10 hours of working, empty the crank

case of oil and refill with clean oil by removing the

crank case oil plug (left hand side of the crank case at

the bottom)

NOTE.

Use good quality compressor lubricating oil.

•

SAE30 or L-DAB 100 over 10°C

•

SAE10 or L-DAB 68 under 10°C

2. After each subsequent 500 hours of operation, again

drain the oil and refill the crank case with clean oil.

3. After each day of

operation, use the drain

cock (11) under the

tank to drain off any

condensate.

4. Regularly check the air

filter cartridge inside the

air filter assembly (17)

and replace the cartridge

when necessary.

14

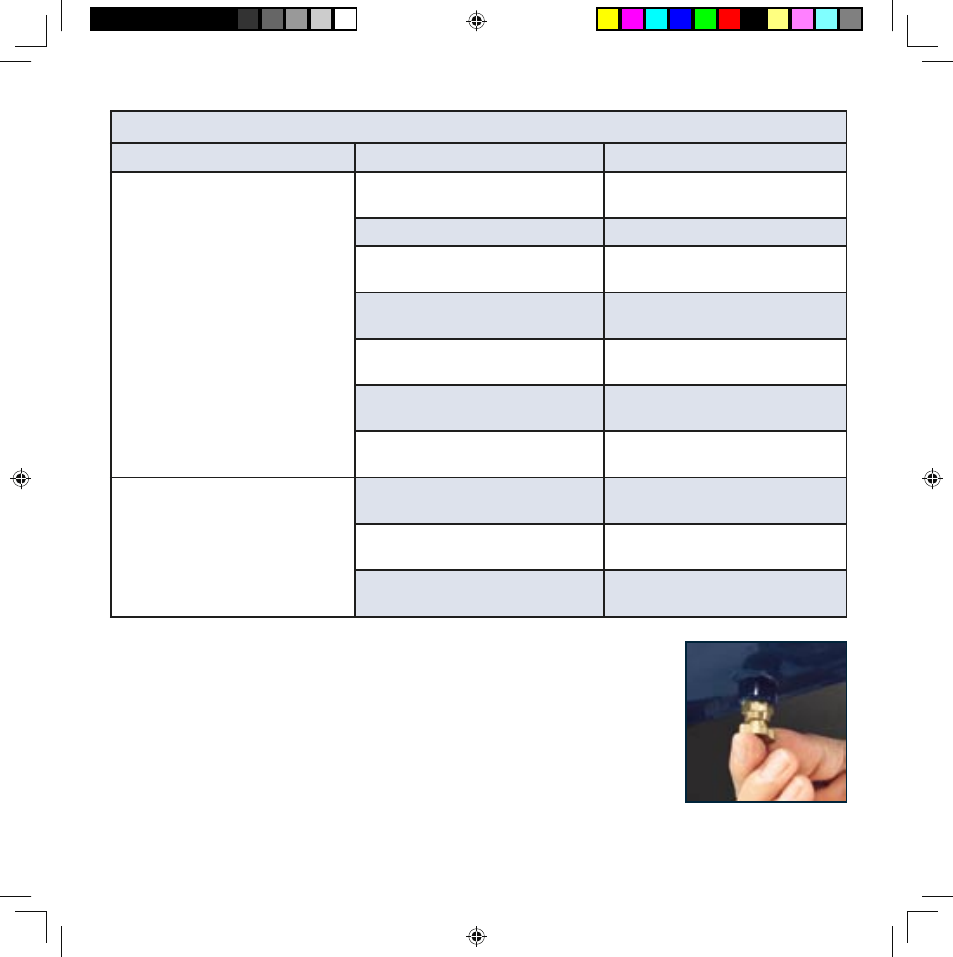

Troubleshooting continued

Trouble

Possible cause

Suggested Remedy

Insufficient pressure or decreased

outlet capacity

Motor running too slow

Use authorised service centre to check

and repair if necessary

Dirty air filter cartridge

Clean or replace the filter cartridge

Leaking safety valve

Use authorised service centre to repair

or replace the switch

Leaking pipe

Use authorised service centre to check

and repair if necessary

Damaged gasket

Use authorised service centre to check

and repair if necessary

Damaged or carbon coated valve seat

Use authorised service centre to check

and repair if necessary

Damaged piston ring or cylinder

Use authorised service centre to check

and repair if necessary

Excessive oil consumption

Oil level too high

Maintain the oil at the correct level

Hole in oil filling cap (14) blocked

Check and clean

Piston ring and/or cylinder worn or

damaged

Use authorised service centre to check

and repair if necessary

AC30G_AC40G

12/8/05, 4:49 PM

14