Graco HUSKY 312877C User Manual

Page 23

Technical Data

312877G

23

* Sound power measured per ISO-9614-2.

** Sound pressure was tested 3.28 ft (1 m) from equipment.

All trademarks mentioned in this manual are the property of their respective owners.

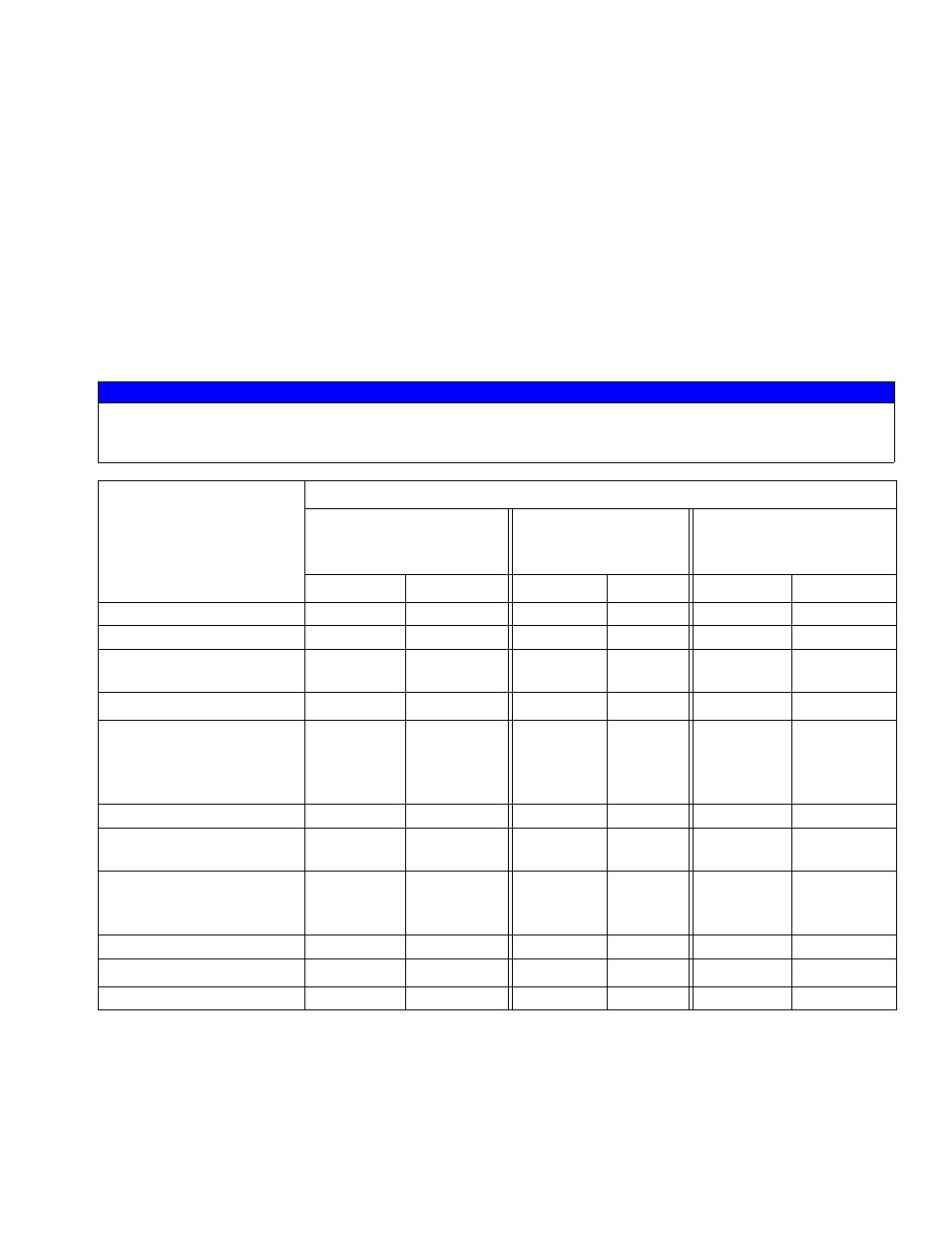

Fluid Temperature Range

* The maximum temperature listed is based on the ATEX standard for T4 temperature classification. If you are

operating in a non-explosive environment, FKM fluoroelastomer’s maximum fluid temperature in aluminum or

stainless steel pumps is 320°F (160°C).

Non-wetted external parts

Aluminum (

1050A

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hastelloy (

1050H

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plastic (

1050P

,

1050C,

and

1050F

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stainless Steel (

1050S

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

aluminum, coated carbon steel

hastelloy, stainless steel, polypropylene

or aluminum (if used in center section)

stainless steel, polypropylene

stainless steel, polypropylene or alumi-

num (if used in center section)

NOTICE

Temperature limits are based on mechanical stress only. Certain chemicals will further limit the fluid temperature

range. Stay within the temperature range of the most-restricted wetted component. Operating at a fluid temperature

that is too high or too low for the components of your pump may cause equipment damage.

Diaphragm/Ball/Seat

Material

Fluid Temperature Range

Aluminum, Hastelloy, or

Stainless Steel Pumps

Polypropylene or

Conductive

Polypropylene Pumps

PVDF Pumps

Fahrenheit

Celsius

Fahrenheit

Celsius

Fahrenheit

Celsius

Acetal (

AC

)

10° to 180°F -12° to 82°C 32° to 150°F 0° to 66°C 10° to 180°F -12° to 82°C

Buna-N (

BN

)

10° to 180°F -12° to 82°C 32° to 150°F 0° to 66°C 10° to 180°F -12° to 82°C

FKM Fluoroelastomer

(

FK

)*

-40° to 275°F -40° to 135°C 32° to 150°F 0° to 66°C 10° to 225°F -12° to 107°C

Geolast

®

(

GE

)

-40° to 150°F -40° to 66°C 32° to 150°F 0° to 66°C 10° to 150°F -12° to 66°C

Neoprene overmolded

diaphragm (

CO

) or

Neoprene check balls

(

CR

or

CW

)

0° to 180°F

-18° to 82°C 32° to 150°F 0° to 66°C 10° to 180°F -12° to 82°C

Polypropylene (

PP

)

32° to 150°F

0° to 66°C

32° to 150°F 0° to 66°C 32° to 150°F

0° to 66°C

PTFE overmolded

diaphragm (

PO

)

40° to 180°F

4° to 82°C

40° to 150°F 4° to 66°C 40° to 180°F 4.0° to 82°C

PTFE check balls or

two-piece PTFE/EPDM

diaphragm (

PT

)

40° to 220°F 4° to 104°C 40° to 150°F 4° to 66°C 40° to 220°F 4° to 104°C

PVDF (

PV

)

10° to 225°F -12° to 107°C 32° to 150°F 0° to 66°C 10° to 225°F -12° to 107°C

Santoprene

®

(

SP

)

-40° to 180°F -40° to 82°C 32° to 150°F 0° to 66°C 10° to 180°F -12° to 82°C

TPE (

TP

)

-20° to 150°F -29° to 66°C 32° to 150°F 0° to 66°C 10° to 150°F -12° to 66°C