Garland MCO-GS-10E User Manual

Page 9

9

ELECTRONIC CONTROL FAILURE CODES

The GARLAND digital control has a self-diagnostic program. If a problem occurs within the digital controller, you may

see one of the "F" codes.

Below is a listing of the "F" codes with explanations:

-F1-

Relay output is enabled when not cooking. If this failure code appears in the display, the cook relay may be on

even if the control is not cooking. The control should be replaced.

-F2-

Over temperature alarm. If this failure code appears in the display the control is sensing an oven temperature

50° or more above the maximum set temperature (500°). This failure may be caused by a faulty sensor.

Check the sensor connection for loose wires.

Replace the sensor and check for proper operation.

If failure continues replace the control.

-F3-

Open sensor circuit. If this failure appears in the display, the control is sensing an open circuit at the sensor

input. This failure is most often caused by a poor connection or broken sensor.

Check sensor connection and leads for broken wires of loose connections. Replace sensor and check for

proper operation. If failure continues replace control.

-F4-

Shorted sensor circuit. If this failure appears in the display, the control is sensing a short circuit at the sensor

input. This failure is most often caused by loose wires at the connection of shorted sensor leads.

Check sensor connection and leads for loose wires. Replace sensor and check for proper operation. If failure

continues replace control.

-F5-

Relay outputs not enabled when cooking. If this failure appears in the display the control cannot turn the

relays on even when cooking. The control should be replaced.

-F6-

No 60 Hz input. The control does not sense the input power. This failure mode is most often the result of a

failed component in the control. However, this failure may also be the result of a very noisy power line. Look

for any large electrical noise producing machinery (such as mixers, compressors, dishwashers etc.). If

possible, turn these machines off. Reapply power to the oven. If the failure repeats, replace the control. If

the failure does not repeat, an electronic control may not work in this application because of noise. You must

isolate the supply circuit.

-F7-

The control has detected that calculated EEPROM check sum is not the same as the expected check sum

retrieved from the EEPROM. When the control detects this error code, it will disable outputs before the alarm

sounds.

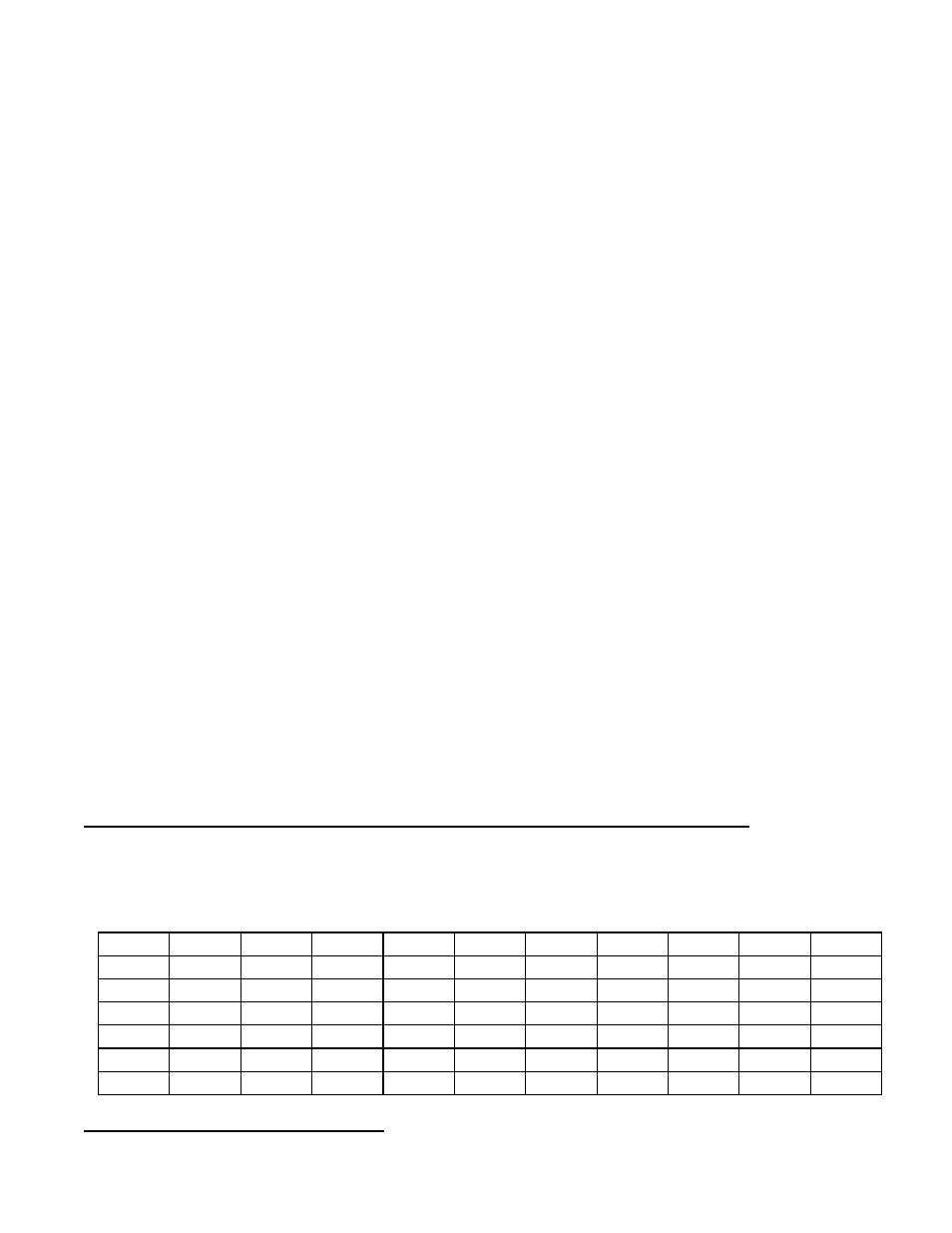

RESISTANCE vs. TEMPERATURE CHART FOR INTERNAL OVEN TEMPERATURE SENSOR

The chart below will provide the Ohms at various temperatures. This will enable you to determine if the temperature

probe is operable.

The chart is in Degrees Fahrenheit. How to use chart, for 350

°

, read down to 300 then across to 50, answer is

1654Ohms of resistance.

TEMP

0°

10°

20°

30°

40°

50°

60°

70°

80°

90°

0°

932

953

974

995

1016

1038

1059

1080

1101

1122

100°

1143

1163

1184

1205

1226

1247

1267

1288

1309

1329

200°

1350

1370

1391

1411

1432

1452

1472

1493

1513

1533

300°

1553

1574

1594

1614

1634

1654

1674

1694

1714

1733

400°

1753

1773

1793

1813

1832

1852

1871

1981

1911

1930

500°

1949

1969

1988

2008

2027

2046

2065

2085

2104

2123

ROBERTSHAW COM6000 CONTROLLER