3 manual transfer and start-up, 4 engine governor adjustments, 3 15 amp fuse – Generac Power Systems 005012-1 User Manual

Page 16: 4 4.0 amp inline fuse, 5 set exercise time switch, 6 system ready led, Figure 3.2 — engine governor adjustment, Stability differential dip switch

14

3.2.3 15 AMP FUSE

This fuse protects the control console’s DC control

circuit against electrical overload. If the fuse has

melted open because of an overload, engine crank-

ing and startup cannot occur. If the fuse needs to be

replaced, use only an identical 15-amp replacement

fuse. (Type AGC)

3.2.4 4.0 AMP INLINE FUSE

This fuse protects the battery charger against electri-

cal overload. If the fuse needs to be replaced, use only

an identical 4-amp replacement fuse (type AG).

NOTE:

This fuse will not remove the + battery input

power from the PCB when it opens. This means

the exercise timer will not be reset.

3.2.5 SET EXERCISE TIME SWITCH

This switch allows programming the generator to

start and exercise automatically. “See Weekly Exercise

Cycle.”

3.2.6 SYSTEM READY LED

The System Ready LED (green) has two main pro-

poses. First, the LED will be ON when the AUTO/

OFF/MANUAL switch is in the AUTO position, utility

is present, and there are no system alarms. This ON

state indicates the system is fully ready for automatic

operation.

The system ready LED will be OFF when the switch

is in the MANUAL or OFF positions.

The system ready LED is also used to indicate the

presence of utility sensing at the PCB when the switch

is either in the AUTO or MANUAL modes. The LED

will flash at the rate of 1/2 second on, 1/2 second off

if the utility sensing level is below the transfer back

threshold.

This secondary function is only available with dip

switch two in the OFF position (standard ATS appli-

cation).

3.3

MANUAL TRANSFER AND

START-UP

To transfer electrical loads to the Standby

(EMERGENCY) power source side and start the

engine manually, refer to the Owner’s Manual of the

particular transfer switch.

3.4

ENGINE GOVERNOR

ADJUSTMENTS

Engine speed governing is also controlled by the

engine control board. Connector J2 on the engine

control board interfaces with a governor driver mod-

ule and the Bosch throttle body. The engine gover-

nor has been set by the factory during final testing

of the generator and, in most cases, should not be

adjusted.

If, however, adjustments are necessary, or a new

engine control board is installed in the generator, the

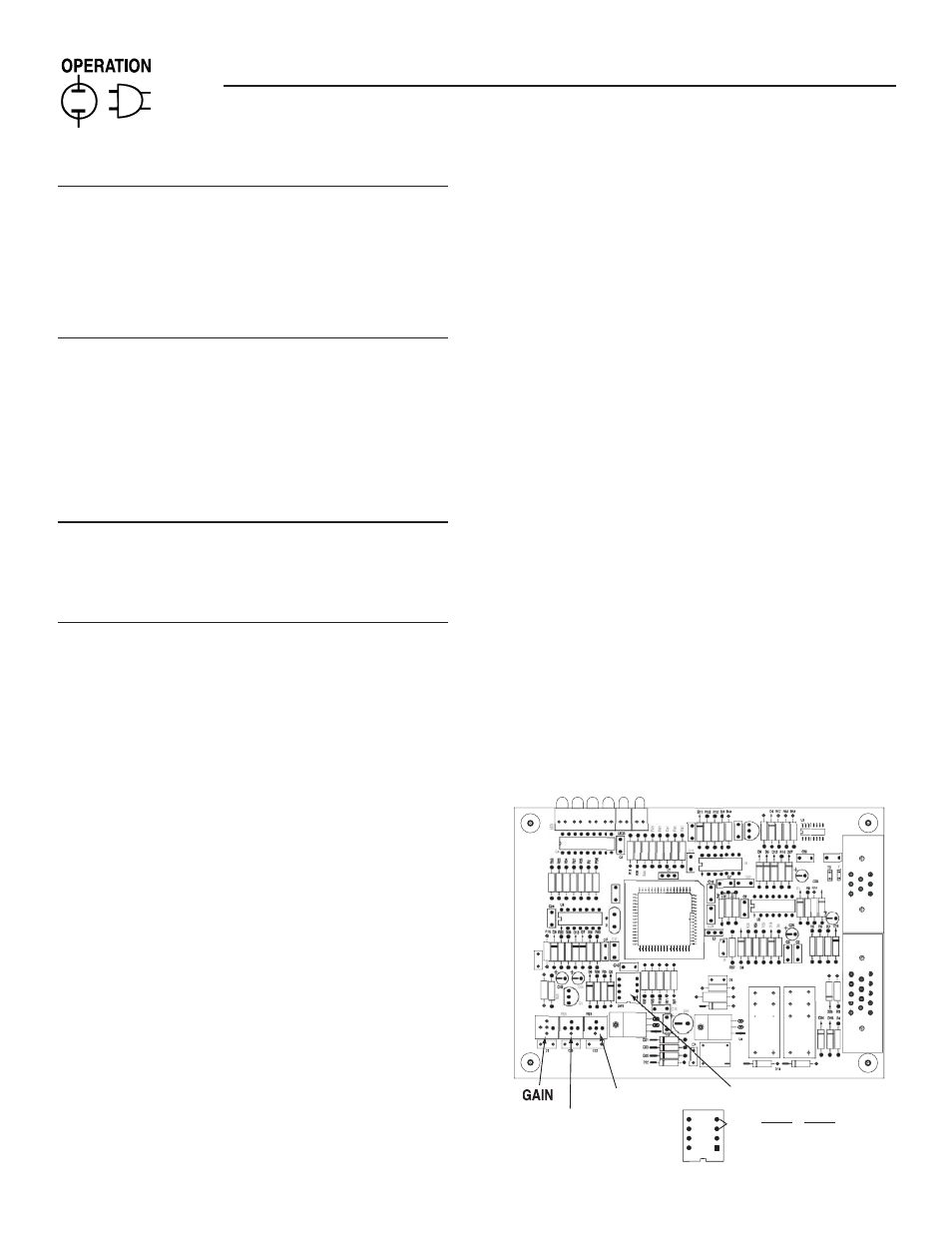

following procedure should be followed (Figure 3.2):

1. Set all three potentiometers (pots) fully counter-

clockwise.

2. Under no load condition, increase the GAIN pot

as much as possible without causing instability.

3. Apply 1/4, 1/2, 3/4 and full load to the unit.

Decrease the GAIN pot if there is instability at any

load point.

4. Under full load condition, increase the stability

pot until the unit returns to 60 Hertz (or 50 Hertz

in 50 Hertz applications).

5. Reduce load to 3/4, 1/2, 1/4 and no load. Decrease

the STABILITY pot if there is instability at any

load point.

6. Adjust differential pot to make the recovery to

load changes even faster and minimize load

change undershoot and overshoot. If it is set too

high, it may introduce oscillations at some load.

It can be set to zero (full CCW) if a small amount

causes oscillations at some load.

Figure 3.2 — Engine Governor Adjustment

PCB# 0E4906 REV.

R49

D17

J2

C2

C26

U7

C27

R44

Q2

D19

C30

RL1

2

L3

LED1

C4

R

25

C9

C21

D10

J1

R48

R1

U1

RL2

1

2

3

4

UNUSED

GTS/ATS

50/60 HZ

POSITION 1

50/60 HZ

ON = 50 HZ

OFF = 60 HZ

POSITION 2

GTS/ATS Select

ON = GTS

OFF = ATS (standard mode)

STABILITY

DIFFERENTIAL

DIP SWITCH

0 0

Section 3 — Operation

40kW Liquid-cooled Generators