Positioning belt bed, Surface sanding on the sanding belt, End sanding on the sanding belt – Global Machinery Company BD1500 User Manual

Page 12: Sanding curved edges

12

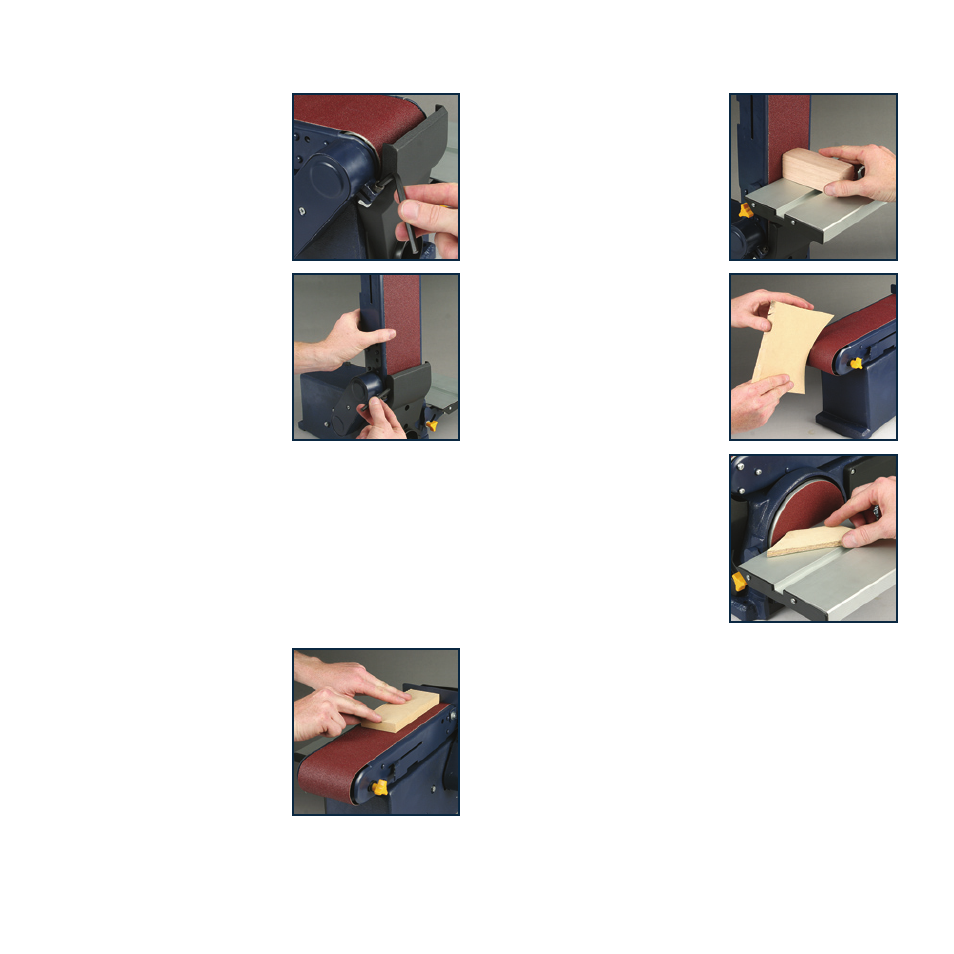

Positioning belt bed

The belt bed locking hex screw

locks the belt bed (12) in a

vertical or horizontal position.

To adjust vertical position:

1. Remove work support (9)

2. Loosen the hex head locking

screw (15) using a 6 mm hex

wrench.

3. Position belt bed and retighten

the hex head locking screw.

Surface sanding on the sanding belt

WARNING:

To avoid injury from slips, jams or thrown

pieces, adjust the backstop to clear the sanding surface by

no more than 1-2 mm.

When checking clearance between the belt and work

support, press the belt flat against the metal beneath it.

1. Hold the work piece firmly with both hands, keeping

fingers away from the sanding belt.

2. Keep the end butted against

the backstop and move

the work evenly across the

sanding belt. Use extra caution

when sanding very thin pieces.

3. When sanding long pieces,

remove the work support.

4. Apply only enough pressure

to allow the sanding belt to

remove any material.

End sanding on the sanding belt

1. It is more convenient to sand

the ends of long workpieces

with the sanding belt in a

vertical position.

2. Move the work evenly across

the sanding belt. For accuracy,

use the mitre gauge.

Sanding curved edges

1. Always sand inside curves on

idler drum as shown.

WARNING:

Never attempt to

sand the ends of a workpiece on

the idler drum. Applying the end

of the workpiece to the idler drum

could cause the work piece to fly

up and result in an injury.

2. Always sand outside curves

on the left hand side of the

sanding disc.

WARNING:

Applying the

workpiece to the right side of the

disc could cause workpiece to fly

up (kickback) and result in injury.