Troubleshooting – Greenheck Fan PVF User Manual

Page 7

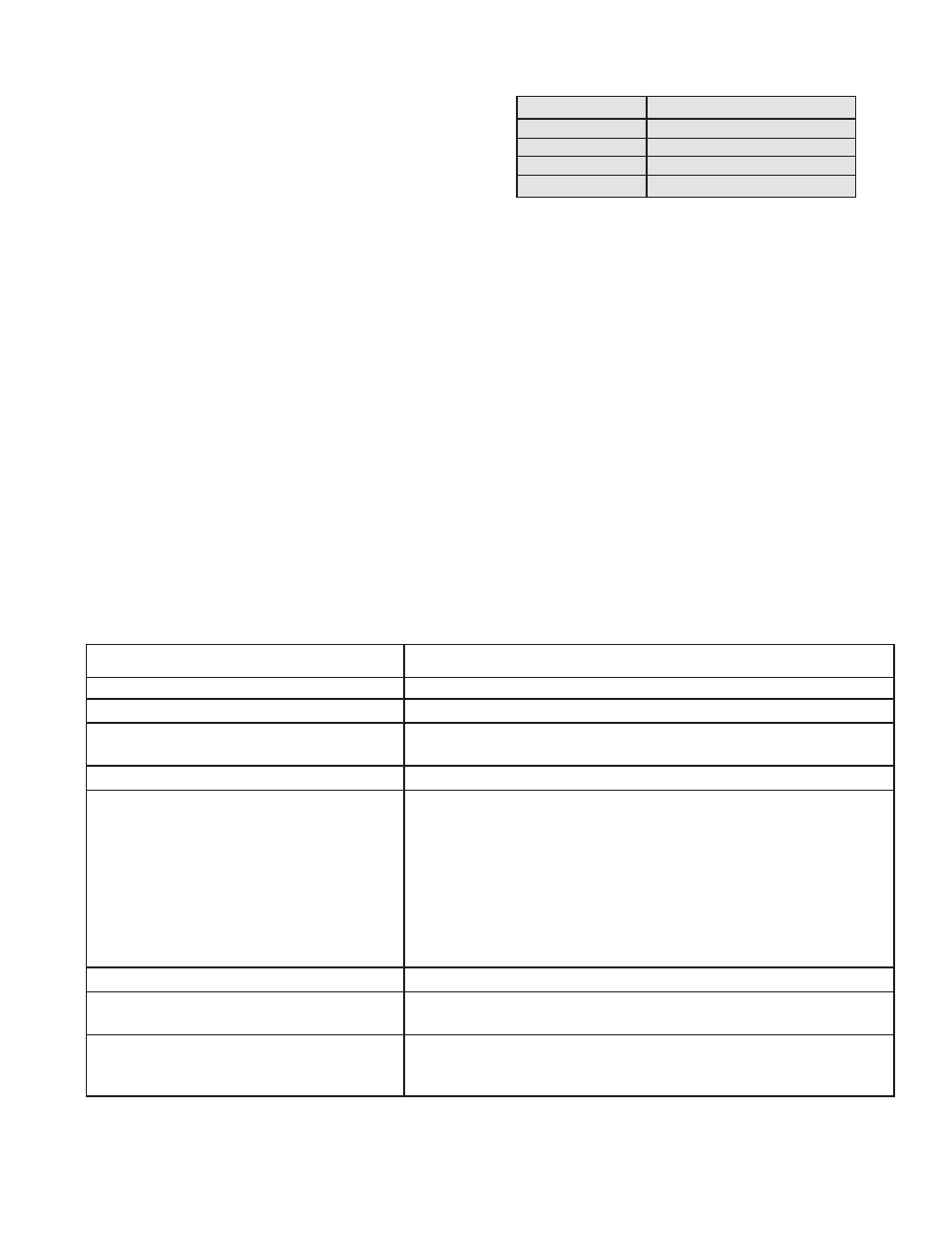

Ignition Control Diagnostic LED

During normal operation, the LED is shut off. The LED

will be on or flashing during a fault condition. If a fault

condition is occurring, turn the unit off and on again. If

the LED is still flashing, refer to the following

troubleshooting section.

LED Indication

Error Mode

Steady on

Internal control failure

1 flash

Air flow fault

2 flashes

Flame with no call for heat

3 flashes

Ignition lockout

Troubleshooting

Possible Cause

Solution

Manual gas valve not open

Open manual valve

Air in the gas line

Bleed gas line

Supply gas pressure too high or too low

Check that supply pressure is between 6 in. wg and 14 in. wg for

natural gas and 11 in. wg and 14 in. wg for LP.

Loose wire connections

Check for tight wire connections.

No spark:

a. Transformer failure

a. Check primary and secondary voltages of transformer. Replace

if necessary.

b. Spark electrode

b. Ensure spark gap is

1

⁄

8

in. and ceramic insulator is not cracked.

Replace if necessary. Electrode is NOT field-adjustable.

c. Spark cable shorted to ground

c. Replace spark cable

d. Ignition controller not grounded

d. Check that the ignition controller is grounded to the furnace

control center.

High limit control tripped

Check unit airflow and manifold pressure.

Faulty combination gas valve

If 24 volts is measured between terminals MV and common, but

valve remains closed, replace valve.

Faulty ignition control

Check diagnostic LED for steady on and for voltage between V1

and V2. If no voltage is present, replace ignition control.

Airflow Fault (1 Flash)

An airflow fault may occur for the following reasons:

• An airflow switch continually monitors the combustion airflow during an ignition sequence. During the initial

call for heat, if the pressure switch contacts are in the closed position for 30 seconds without an output to

the combustion blower, an airflow fault will be declared. The control will remain in this mode with the

combustion blower off.

• After the combustion blower output (L1 and IND) is energized and the airflow switch remains open for more

than 30 seconds, an airflow fault will be declared. The control will stay in this mode with the combustion

blower on, waiting for the airflow switch to close.

• If the airflow signal is lost while the burner is firing, the control will immediately de-energize the gas valve

and the combustion blower will remain on. If the call for heat remains, the control will wait for proper airflow

to return. If proper airflow is not detected after 30 seconds, an airflow fault will be declared. If proper airflow

is detected at any time, a normal ignition sequence will begin.

Once proper airflow is detected, the normal Sequence Of Operation for ignition will follow (see page 4).

Flame Fault (2 Flashes)

If the main valve fails to close completely and maintains a flame, the full-time flame sense circuit will detect it and

energize the combustion blower. Should the main valve later close completely and remove the flame signal, the

combustion blower will be de-energized.

Ignition Lockout (3 Flashes)

7